👨🏭welding Safety Welder Uses Improper Ppe

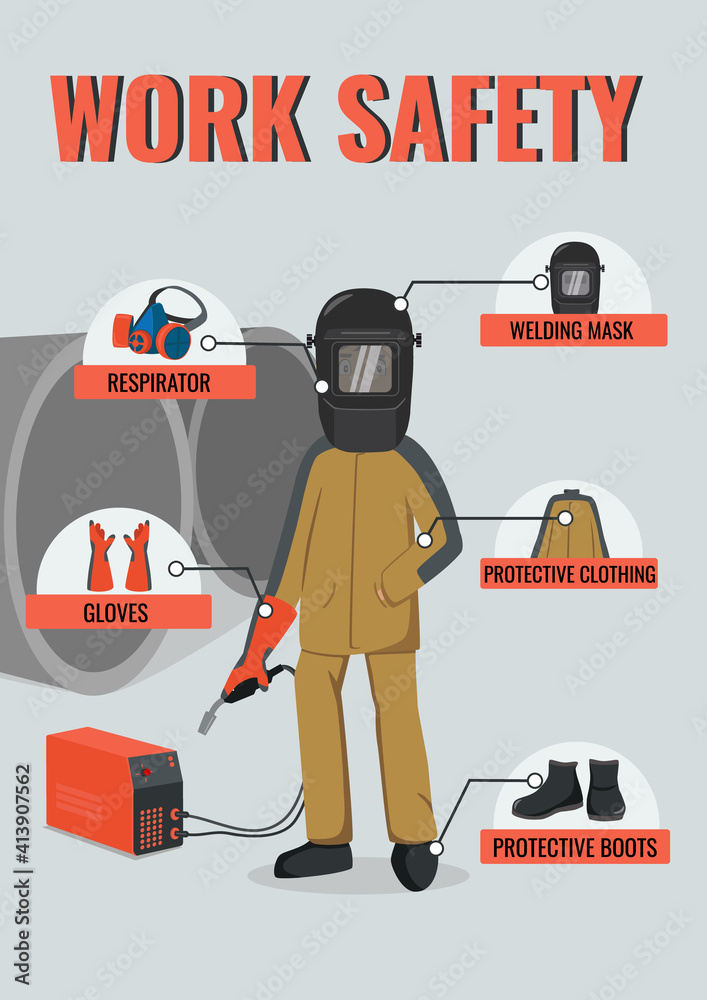

Welder Wearing Welding Mask Respirator Gloves Protective Clothing 👨🏭welder safety: welding related incidents such as burns, eye injuries, and other skin injuries and even deaths due to explosions, electrocutions, and asp. Ppe forms a protective barrier between the welder and the various health and safety risks associated with welding. ensuring that the right ppe is used correctly can significantly reduce accidents and injuries, creating a safer and more productive work environment. personal protective equipment for welders is not a one size fits all category. it.

Welding Safety Tips And Guide For Beginners Welding Judge When welding goes awry: common pitfalls. welding, while essential for construction and fabrication, can also lead to mishaps if safety precautions are overlooked. here are a few scenarios where things can take an unfortunate turn: arc flash burns: an arc flash occurs when intense light and heat are emitted during welding. if a welder isn’t. Eye and face protectors should have distinctive markings to identify the manufacturer and their class. classifications of common protectors for welding operations are listed below: class 2c – direct non ventilated goggles with non ionizing radiation protection. class 3 – welding helmets. class 4 welding hand shields. Wearing appropriate ppe like welding helmets and eye protection gear like goggles to protect workers’ eyes and head from hot slag, sparks, intense light, and chemical burns. welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure there are no smoldering fires. consider applying the top 10. The following is an overview of the different types of safety equipment, including personal protective equipment (ppe) like helmets, gloves, aprons, and respirators. 1. welding helmets. welding helmets are essential for protecting your eyes and face from the intense light and heat of welding.

Work Safety Isometric Welder Wearing Welding Mask Respirator Gloves Wearing appropriate ppe like welding helmets and eye protection gear like goggles to protect workers’ eyes and head from hot slag, sparks, intense light, and chemical burns. welding workers should remain in the work area for at least 30 minutes after finishing welding to ensure there are no smoldering fires. consider applying the top 10. The following is an overview of the different types of safety equipment, including personal protective equipment (ppe) like helmets, gloves, aprons, and respirators. 1. welding helmets. welding helmets are essential for protecting your eyes and face from the intense light and heat of welding. Here’s a breakdown of essential welding ppe and their importance: 1. welding helmets. welding helmets serve as a welder’s first line of defense against many potential hazards. their primary purpose is safeguarding the eyes and face from harmful ultraviolet (uv) and infrared (ir) rays emitted during welding. Welding is a special process as defined in iso 9001 and dangerous too, and it requires the use of personal protective equipment (ppe) in order to maintain safety for those performing the task. ppe is used to protect welders from hazards associated with welding such as exposure to ultraviolet radiation, sparks, heat, fumes and other airborne particles.

Comments are closed.