3 Main Types Of Pneumatic Cylinders With Application Linquip

3 Main Types Of Pneumatic Cylinders With Application Linquip Single acting pneumatic cylinders. double acting pneumatic cylinders. telescoping pneumatic cylinders. the functions of these three common pneumatic cylinders are discussed below. each of these cylinders has a distinct application and thus the best one for the job will be determined by the current project. Applications. read more on linquip 3 main types of pneumatic cylinders with application what are pneumatic pipes, tubes, and hoses it is essential to distinguish what type of vessels are being used in the system to determine. what fittings are suitable.

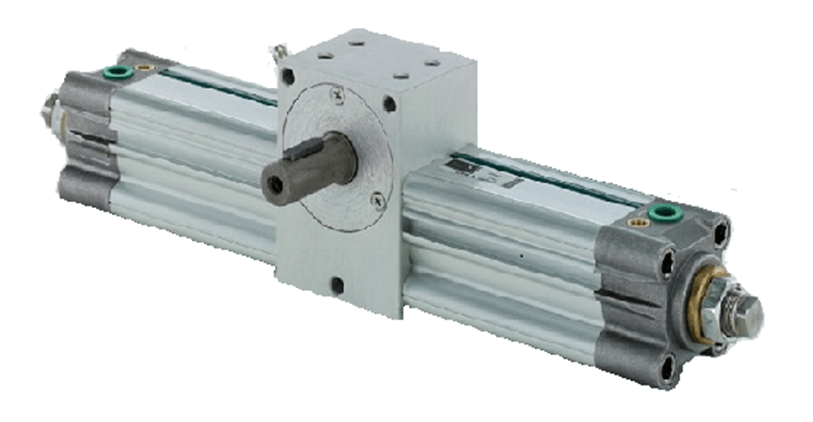

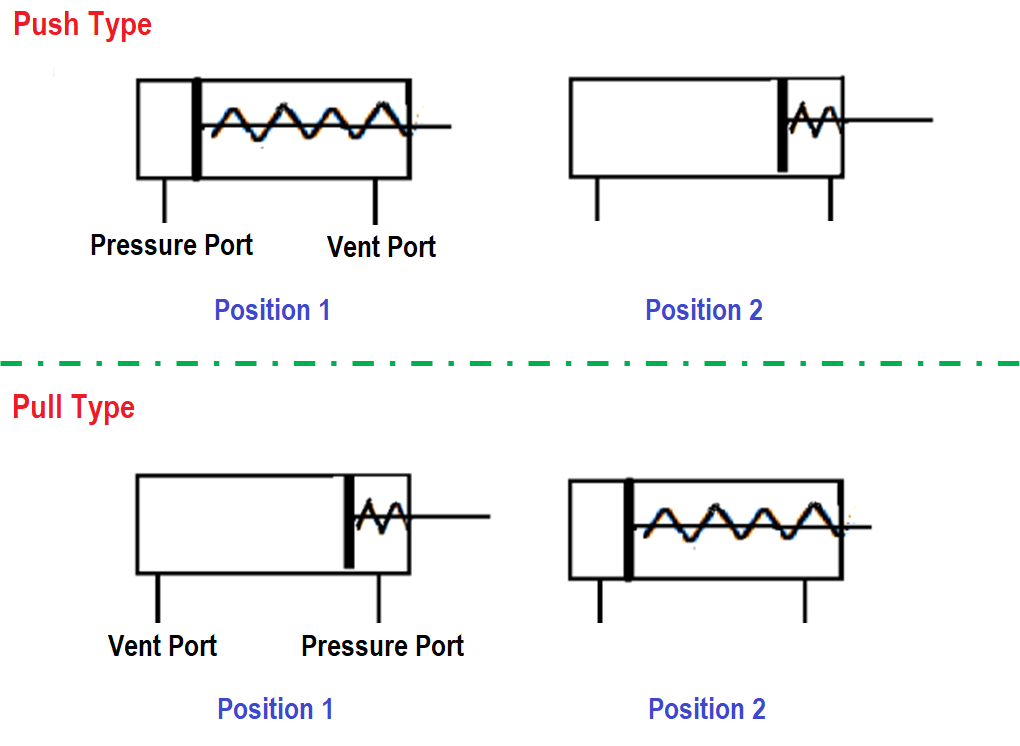

3 Main Types Of Pneumatic Cylinders With Application Linquip Pneumatic cylinder. a pneumatic cylinder is a special type device that uses the energy created by compressed gas to create a force for alternating linear motion. since that “pneuma” is the greek word for air, a pneumatic cylinder may also be called an air cylinder. a force is applied into the piston, pushing it in the desired direction. A pneumatic cylinder may also be known as an air cylinder or a pneumatic actuator. they are mechanical components that are used to produce power or movement from the air or compressed gas. they are a cheap, cost effective way to produce linear or rotary motion. pneumatic cylinders can also be known as pneumatic actuators or pneumatic drives. This guide has explored various aspects of pneumatic cylinders, from their basic functioning and types to the considerations necessary for appropriate selection. we’ve seen how different types of cylinders, such as single acting, double acting, and rodless cylinders, cater to specific application needs. additionally, the importance of. This type controls the piston’s motions and works in both directions. the only downside of double acting is that it consumes more energy and does a complicated operation that is unsuitable for applications needing a cylinder to remain in a particular position. additionally, it has more stroke length and force. 5 types of pneumatic cylinder.

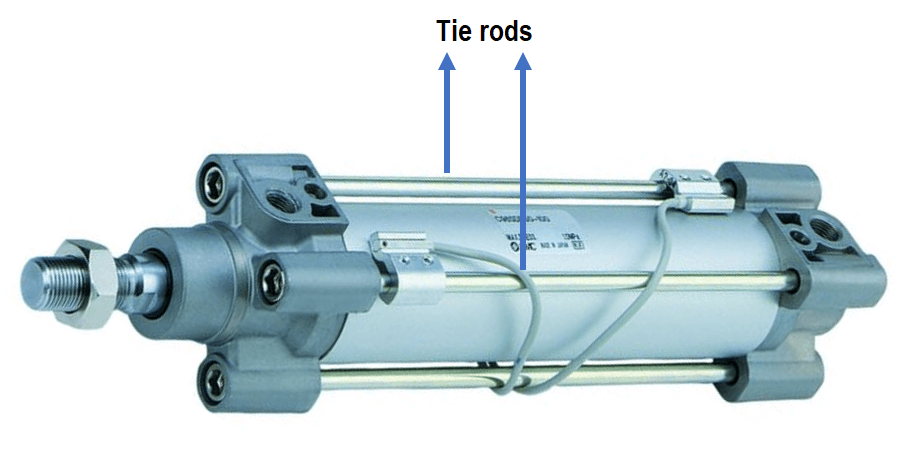

3 Main Types Of Pneumatic Cylinders With Application Linquip This guide has explored various aspects of pneumatic cylinders, from their basic functioning and types to the considerations necessary for appropriate selection. we’ve seen how different types of cylinders, such as single acting, double acting, and rodless cylinders, cater to specific application needs. additionally, the importance of. This type controls the piston’s motions and works in both directions. the only downside of double acting is that it consumes more energy and does a complicated operation that is unsuitable for applications needing a cylinder to remain in a particular position. additionally, it has more stroke length and force. 5 types of pneumatic cylinder. Pneumatic cylinders also called air cylinders are the final component of the pneumatic or compressed air control mechanical device. air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. the mechanical energy produces linear or rotary motion. the pneumatic air cylinder functions as the actuator in the. January 10, 2018 by charles kolstad. figure 1: pneumatic cylinder. a pneumatic cylinder converts compressed air energy into a reciprocating linear motion. they are simple to use and are a cost efficient solution to move loads linearly, making them commonly used in the automation of machines and industrial processes.

Pneumatic вђ Hidraulika Lasko Co Pneumatic cylinders also called air cylinders are the final component of the pneumatic or compressed air control mechanical device. air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. the mechanical energy produces linear or rotary motion. the pneumatic air cylinder functions as the actuator in the. January 10, 2018 by charles kolstad. figure 1: pneumatic cylinder. a pneumatic cylinder converts compressed air energy into a reciprocating linear motion. they are simple to use and are a cost efficient solution to move loads linearly, making them commonly used in the automation of machines and industrial processes.

3 Main Types Of Pneumatic Cylinders With Application Linquip

Comments are closed.