9 Ways Companies Are Safeguarding Against Future Supply Chain Disruptions

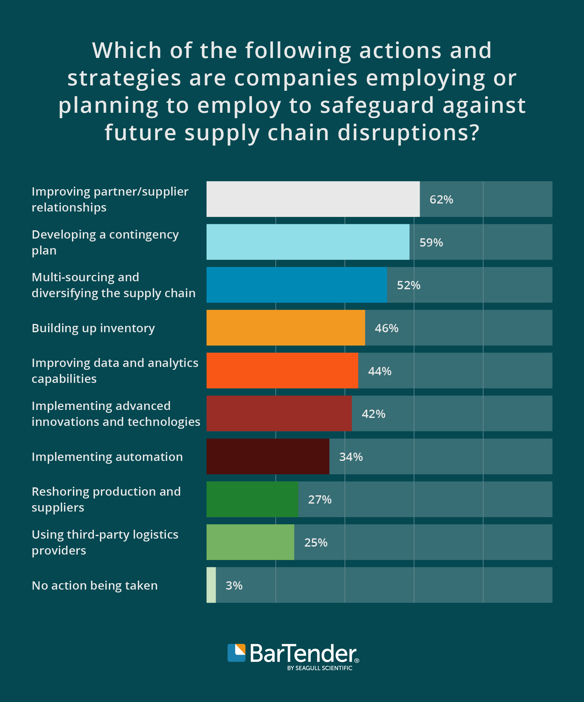

Survey How Companies Are Safeguarding Against Future Supply Chainођ 1. improving partner and supplier relationships. regarding strategies companies are employing or planning to employ to safeguard against future supply chain disruptions, our survey uncovered that improving partner and supplier relationships is the most common, followed by developing a contingency plan. Organizations around the world are still dealing with disruptions placed on global supply chains as a result of the covid 19 pandemic.to understand how compa.

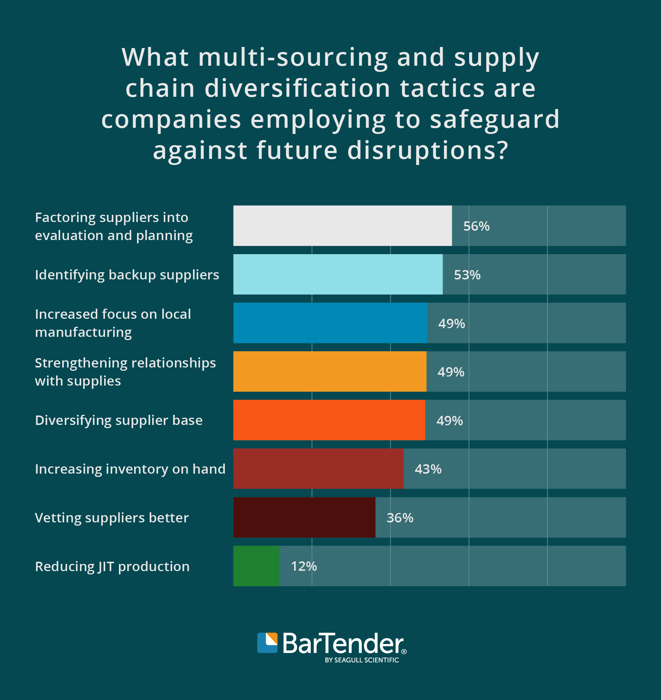

Survey How Companies Are Safeguarding Against Future Supply Chainођ Most respondents expect this momentum to continue. sixty nine percent of supply chain leaders told us that dual sourcing will continue to be relevant in 2022 and beyond, and 51 percent think the same about regionalization. 2. overall, our survey shows that disruption has reshaped almost every supply chain. ninety seven percent of respondents. The first of these new priorities, resilience, addresses the challenges that have made supply chain a widespread topic of conversation. the second, agility, will equip companies with the ability to meet rapidly evolving, and increasingly volatile, customer and consumer needs. the third, sustainability, recognizes the key role that supply chains. They’ll have supply chains that are more resilient to future disruptions. five key logistics actions. improve visibility: use an integrated logistics control tower to get real time visibility into operations. increase flexibility: repurpose assets, inventory and capabilities to balance supply and demand. Designing an integrated nerve center. in this stage, three actions can be critical to building resilient supply chains: creating a nerve center for the supply chain, simulating and planning for extreme disruptions, and reevaluating just in time strategies. create a nerve center to consolidate organizational responses.

Survey How Companies Are Safeguarding Against Future Supply Chainођ They’ll have supply chains that are more resilient to future disruptions. five key logistics actions. improve visibility: use an integrated logistics control tower to get real time visibility into operations. increase flexibility: repurpose assets, inventory and capabilities to balance supply and demand. Designing an integrated nerve center. in this stage, three actions can be critical to building resilient supply chains: creating a nerve center for the supply chain, simulating and planning for extreme disruptions, and reevaluating just in time strategies. create a nerve center to consolidate organizational responses. Companies are sufficiently protected against future disruptions in supply chains and operations, with the remaining 88% urgently needing additional measures aimed at building resilience. leaders from across the public and private sectors need to build on recent experience and stress test production systems if both the global economy and companies. Most supply chain disruptions, after all, have limited geographical extent and conform to the standard single trough, limited duration profile outlined by sheffi and rice back in 2005. in sharp contrast, the impact of the pandemic on supply chains has been global, prolonged, and comprised a series of major shocks to companies’ logistical systems.

Comments are closed.