A Production Line In A Factory With Large Hooks Carrying Materials

A Production Line In A Factory With Large Hooks Carrying Materials “a production line in a factory with large hooks carrying materials” by ant rozetsky on unsplash you probably use git multiple times a day, even multiple times an hour. Production line. a production line is a set of sequential operations established in a factory where components are assembled to make a finished article or where materials are put through a refining process to produce an end product that is suitable for onward consumption. typically, raw materials such as metal ores or agricultural products such.

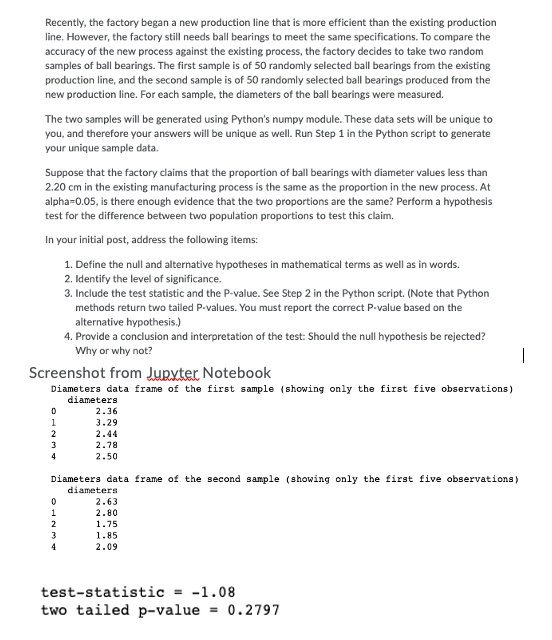

Solved Recently The Factory Began A New Production Line Chegg Line layout strategies – part 1: the big picture. in flow shops, you have a production line of some sort. this may be an assembly line or a manufacturing line; this may be automatic or manual. in lean, you often hear about the famous u line. while this is a great solution, it may not fit all problems. depending on the surrounding conditions. Main consideration for production line layout design. two of the most basic elements of lean manufacturing rely on you optimising workflow and minimising waste. the way manufacturing workstations, machinery, and tools are arranged can affect everything from productivity and throughput to ergonomics. The first step in improving a production line’s efficiency is to evaluate its current state, and below are the key things to consider. 1. identifying bottlenecks via observation. a ‘bottleneck” is any point in the manufacturing process that experiences a slowdown or a complete halt. Principle 4: optimize material flow through the plant. one of the most important principles in production layout planning is optimizing material flow through the facility. this means that you need to ensure that materials move through production in the most efficient way possible. to achieve this, you need to consider the layout of the facility.

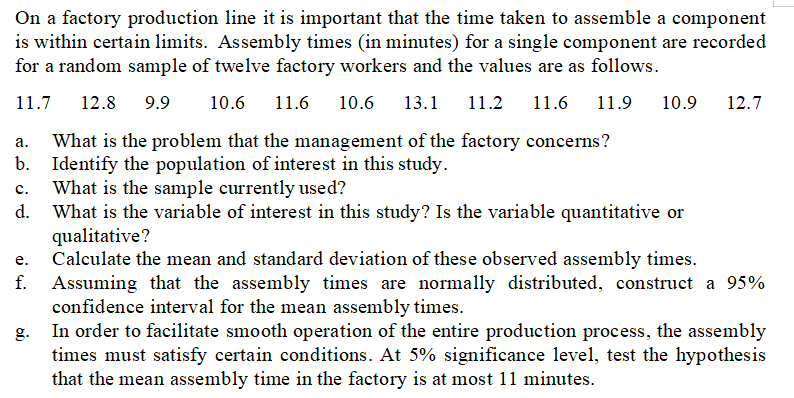

On A Factory Production Line It Is Important That The Chegg The first step in improving a production line’s efficiency is to evaluate its current state, and below are the key things to consider. 1. identifying bottlenecks via observation. a ‘bottleneck” is any point in the manufacturing process that experiences a slowdown or a complete halt. Principle 4: optimize material flow through the plant. one of the most important principles in production layout planning is optimizing material flow through the facility. this means that you need to ensure that materials move through production in the most efficient way possible. to achieve this, you need to consider the layout of the facility. The best way of keeping every order on target is to track milestones at key stages, including: 1. pre production. a lot of things must come together before a production line can run. details depend on industry and product, but common examples include: material must be of the required standard. colors must match. This project features a simulated production line using factory io and siemens tia portal, controlled by a simatic s7 1500 plc. it automates machining, sorting, and assembly from raw materials to finished products. the custom hmi interface provides monitoring and control, with alarms for fault detection to ensure efficient operation.

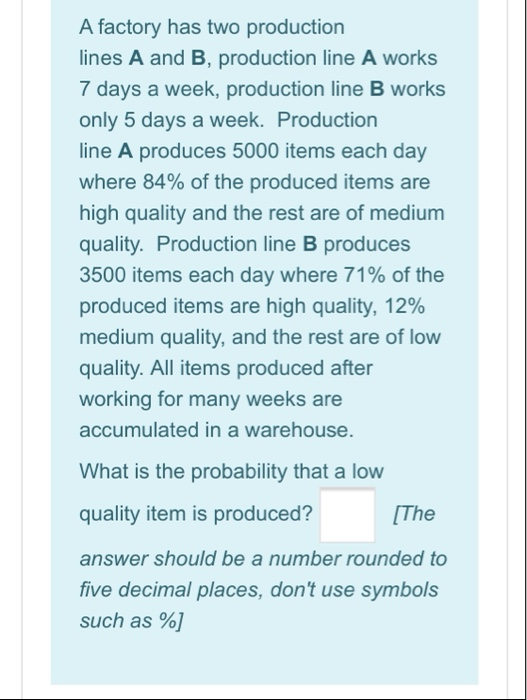

Solved A Factory Uses Three Production Lines To Manufacture Chegg The best way of keeping every order on target is to track milestones at key stages, including: 1. pre production. a lot of things must come together before a production line can run. details depend on industry and product, but common examples include: material must be of the required standard. colors must match. This project features a simulated production line using factory io and siemens tia portal, controlled by a simatic s7 1500 plc. it automates machining, sorting, and assembly from raw materials to finished products. the custom hmi interface provides monitoring and control, with alarms for fault detection to ensure efficient operation.

Solved A Factory Has Two Production Lines A And B Chegg

Comments are closed.