A Tip For Taking Static Pressure Readings

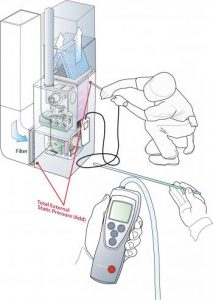

A Tip For Taking Static Pressure Readings Youtube Commercial testing can have a range of 0 to 10”, although a 0” to 5” scale will do for most systems. you’ll want a minimum accuracy of ±3% with a minimum resolution of .01” water column. larger scale manometers lack the accuracy you need. be sure the manometer has at least two pressure ports, one positive and one negative. An hvac technician taking a static pressure measurement. step 2: drill test ports using a 3 8′ drill bit with a metal piercing tip. a bullet tip drill makes a clean round port. so make sure to use your drill bit sheath (described above) to help prevent you from drilling into the coil.

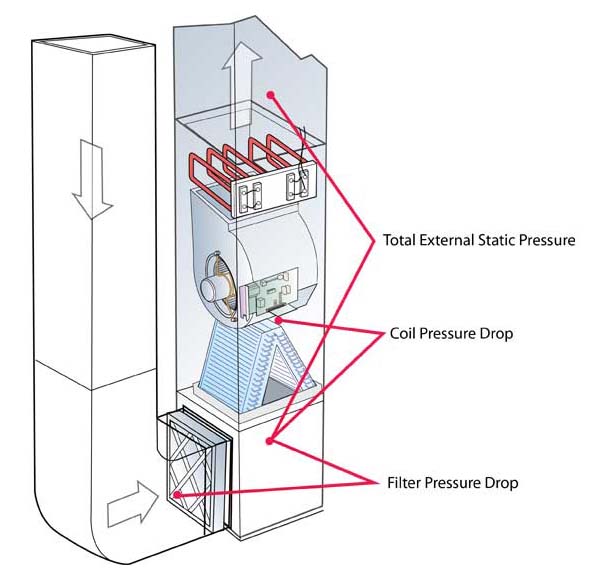

Static Pressure Measurements In Six Easy Steps Hvac Today Step 4: read the supply or positive ( ) static pressure by inserting the static pressure tip into the test port with the tip facing into the airflow. the magnet on the tip will hold it in place while the value is read and recorded. this measurement is the pressure the fan is “seeing” on the supply side of the system. 1. plug your pressure probes into the digital manometer and turn it on. generally, a manometer will have 2 inputs for pressure probes: channel a and channel b. pressure hoses look like long, rubber tubes, and the probes look like small metal hooks. attach your pressure hoses to each input point and then attach the static pressure probes to each. Find and record equipment maximum rated total external static pressure (tesp) from the indoor nameplate. hook up your manometer, tubing, and static pressure tip. turn on the equipment so it operates at the highest blower speed. measure and record your four static pressure readings. calculate tesp and pressure drops. Mistake #2 – measuring in the wrong location. one mistake made when measuring static pressure is to assume the condition of the blower wheel. a dirty blower wheel makes static pressure readings look awesome, because the fan isn’t moving the proper airflow. this is the second most common mistake. there are multiple ways to measure static.

Six Tips To Improve Static Pressure Measurements 2020 09 20 Achr News Find and record equipment maximum rated total external static pressure (tesp) from the indoor nameplate. hook up your manometer, tubing, and static pressure tip. turn on the equipment so it operates at the highest blower speed. measure and record your four static pressure readings. calculate tesp and pressure drops. Mistake #2 – measuring in the wrong location. one mistake made when measuring static pressure is to assume the condition of the blower wheel. a dirty blower wheel makes static pressure readings look awesome, because the fan isn’t moving the proper airflow. this is the second most common mistake. there are multiple ways to measure static. A static pressure tip is a small metal tube about four inches long. it costs around $10 to $15 and is available across the industry. pressure in the duct system called velocity pressure and diverts it away from the small holes near the tip. this action allows only static pressure to enter the tip and display on the manometer. Begin with installing test ports in the proper locations and interpreting nameplate information. then show them how to take the individual readings and calculate the different static pressure measurements. don’t assume a technician’s knowledge level at this point, and keep it simple for best success. step two: support.

Total External Static Pressure Testing T E S P вђ Johnstone Supply A static pressure tip is a small metal tube about four inches long. it costs around $10 to $15 and is available across the industry. pressure in the duct system called velocity pressure and diverts it away from the small holes near the tip. this action allows only static pressure to enter the tip and display on the manometer. Begin with installing test ports in the proper locations and interpreting nameplate information. then show them how to take the individual readings and calculate the different static pressure measurements. don’t assume a technician’s knowledge level at this point, and keep it simple for best success. step two: support.

Comments are closed.