Amica Chips Installs Elea Pef Systems For Yield And Quality Improvement

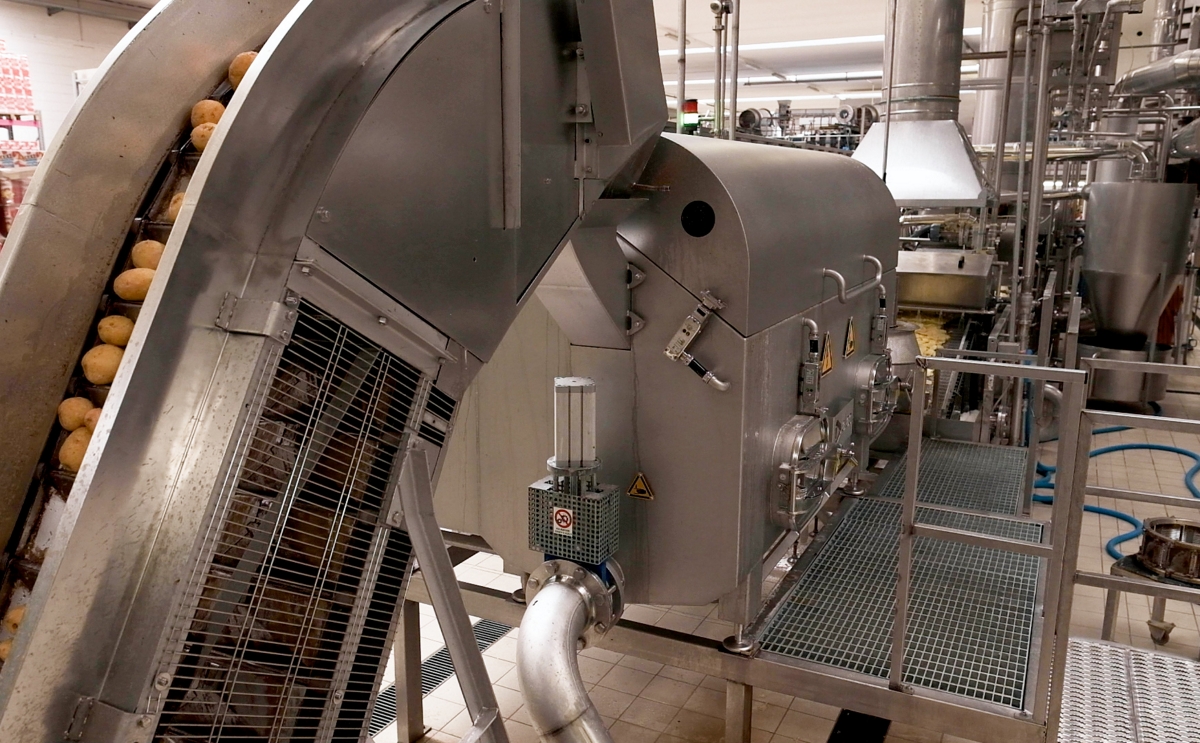

Amica Chips Installs Elea Pef Systems For Yield And Quality Improvement Product quality is improved, as a smoother slice surface causes less oil uptake, a better seasoning adhesion and a crunchier product. after successful testing in autumn 2020 the fourth elea pef advantage b 1 system has been installed at amica chips. the units have a capacity of up to 6 t h of tuber processing. Product quality was also improved because a smoother slice surface causes less oil uptake, a better seasoning adhesion and a crunchier product. after successful testing, in autumn 2020, the fourth elea pef advantage b 1 system has been installed at amica chips. the units have a capacity of up to 6 t h of tuber processing.

Amica Chips Installs Elea Pef Systems For Yield And Quality Improvement Amica spa is a potato chips manufacturer based in cistglioni delle stivere, italy. the company has been founded in 1990 by alfredo moratti and andrea romano and since then has grown to be a leader in the potato chips market with more than 250 employees and product export into more than 20 countries. Product quality was also improved because a smoother slice surface causes less oil uptake, a better seasoning adhesion and a crunchier product. after successful testing, in autumn 2020, the fourth elea pef advantage b 1 system has been installed at amica chips. the units have a capacity of up to 6 t h of tuber processing. Amica chips installs elea pef systems for yield and quality improvement. italian potato chips manufacturer amica has installed an elea pulsed electric field (pef) system following a series of tests earlier this year. italy. october 21, 2015. Elea pef advantage b 1000 850. the pef advantage b 1000 850 is our highest capacity belt system capable of processing up to 100 t h of roots, tubers and fruits. the feature packed new design improves capacity, flexibility, safety, process monitoring and optimisation, energy saving, installation, upgradeability. and more.

Amica Chips Installs Elea Pef Systems For Yield And Quality Improvement Amica chips installs elea pef systems for yield and quality improvement. italian potato chips manufacturer amica has installed an elea pulsed electric field (pef) system following a series of tests earlier this year. italy. october 21, 2015. Elea pef advantage b 1000 850. the pef advantage b 1000 850 is our highest capacity belt system capable of processing up to 100 t h of roots, tubers and fruits. the feature packed new design improves capacity, flexibility, safety, process monitoring and optimisation, energy saving, installation, upgradeability. and more. The first pulsed electric field (pef) system was installed in the potato processing industry in 2010. nowadays, over 100 machines are in use in the industry, most of them for french fries and potato chips (elea gmbh 2020 ). in the past, a preheater was applied to soften the raw potato making it processable for french fry production. For example, the elea pef advantage™ belt systems manufactured by the company german institute of food technologies (dil) elea (quakenbrück, germany) have been successfully used throughout the potato processing industry (e.g. chips and fries), and the processing capacity reaches up to 70 t h (dil elea, 2020). compared with these countries.

Comments are closed.