An Entire Guide Of Diaphragm Pump Shinjo Valve

Diaphragm Pump Manufacturers India Diaphragm Pump Suppliers Factor 3 when selecting a diaphragm pump materials the pump consists of diaphragm pumps can be found in a number of material builds. generally, the most typical options that are offered for diaphragm pump materials range from the material the ball and seat from the pump consist of, and also the material of the pump body consists of. China diaphragm pump manufacturer: flow rate 0 30 m3 h, lift head 0 50 m, size 1 2” ~4”, material stainless steel , cast iron,aluminium alloy,fluoroplastic, ptfe , pfa.

Pneumatic Diaphragm Control Valve Din 3202 F1 Dn80 Control Valves Capacity range 90 4900lph, 16 400bar jydr series hydraulic diaphragm pumps are rugged construction with dependable performance. the pump is designed with three automatic valves (internal relief valve, oil make up valve, position limit valve), to keep the entire system hydraulically balanced for trouble free dosing. Contact us. if you have any questions, please contact us by phone below, we will do our best to answer your questions. time 9:00 ~ 17:00. china diaphragm pump factory: flow rate 0 30 m3 h, lift head 0 50 m, size 1 2” ~4”, material stainless steel , cast iron,aluminium alloy,fluoroplastic, ptfe , pfa. Diaphragm pumps. material: stainless steel, cast iron,aluminium alloy, fluoroplastic, ptfe , pfa, etc. size: 1 2 inch 4 inch, dn10mm dn100mm. flow rate (q) : 0 30 (m3 h). lift head (h) : 0 50 (m). a diaphragm pump is also referred to as a membrane pump which is really a positive displacement pump that utilizes a mix of the reciprocating. Flapper vs. ball valve diaphragm pumps. due to the pumping action of diaphragm pumps, check valves are needed to ensure the liquid inside is pumped in a single direction preventing backflow and potential leaks and contamination. at wastecorp, our heavy duty mud sucker pumps come with two valve options: flapper or ball valves.

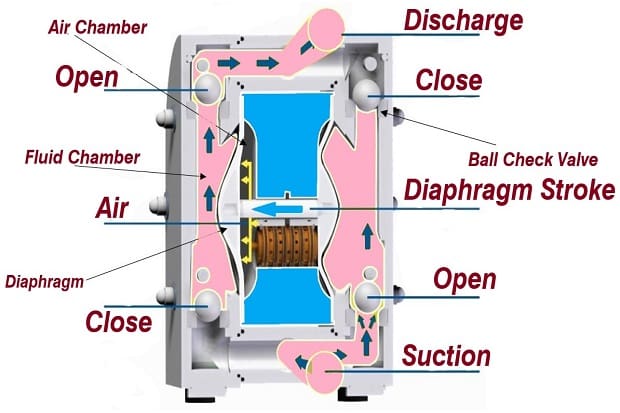

Diaphragm Pump Usages And Applications Shinjo Diaphragm pumps. material: stainless steel, cast iron,aluminium alloy, fluoroplastic, ptfe , pfa, etc. size: 1 2 inch 4 inch, dn10mm dn100mm. flow rate (q) : 0 30 (m3 h). lift head (h) : 0 50 (m). a diaphragm pump is also referred to as a membrane pump which is really a positive displacement pump that utilizes a mix of the reciprocating. Flapper vs. ball valve diaphragm pumps. due to the pumping action of diaphragm pumps, check valves are needed to ensure the liquid inside is pumped in a single direction preventing backflow and potential leaks and contamination. at wastecorp, our heavy duty mud sucker pumps come with two valve options: flapper or ball valves. With a 2:1 pump, the diaphragm pump is capable of producing close to 200 psi discharge pressure. these types of pumps are excellent for filter press applications. 14. no pressure relief or bypass needed due to the fact that discharge pressure cannot exceed air pressure or the pump simply stops, there is no need for pressure relief at the pump. Their core component, a flexible diaphragm, separates the fluid being pumped from the driving mechanism, allowing for the contamination free movement of various fluids. these pumps include a pump chamber, inlet and outlet valves, and a driving mechanism. the diaphragm flexes back and forth, creating a variable volume within the pump chamber.

An Entire Guide Of Diaphragm Pump Shinjo Valve With a 2:1 pump, the diaphragm pump is capable of producing close to 200 psi discharge pressure. these types of pumps are excellent for filter press applications. 14. no pressure relief or bypass needed due to the fact that discharge pressure cannot exceed air pressure or the pump simply stops, there is no need for pressure relief at the pump. Their core component, a flexible diaphragm, separates the fluid being pumped from the driving mechanism, allowing for the contamination free movement of various fluids. these pumps include a pump chamber, inlet and outlet valves, and a driving mechanism. the diaphragm flexes back and forth, creating a variable volume within the pump chamber.

Comments are closed.