An Introduction To Hydraulic Cylinders Types And Selection

A Guide To Hydraulic Cylinders Primary Fluid Power In most hydraulic cylinders, the barrel and the bottom are welded together; this can damage the inside of the barrel if done poorly. therefore, some hydraulic cylinder designs have a screwed or flanged connection from the cylinder end cap to the barrel. in this type the cylinder barrel can be disassembled and repaired in future. cylinder head. One type of hydraulic cylinder we offer at southern hydraulic cylinder is the welded cylinder. it is a smooth cylinder that uses heavy duty housing, which provides stability. this type of cylinder must have a barrel that is durable enough to withstand mechanical forces and features enough of the rigidity needed to support the actuator body loads.

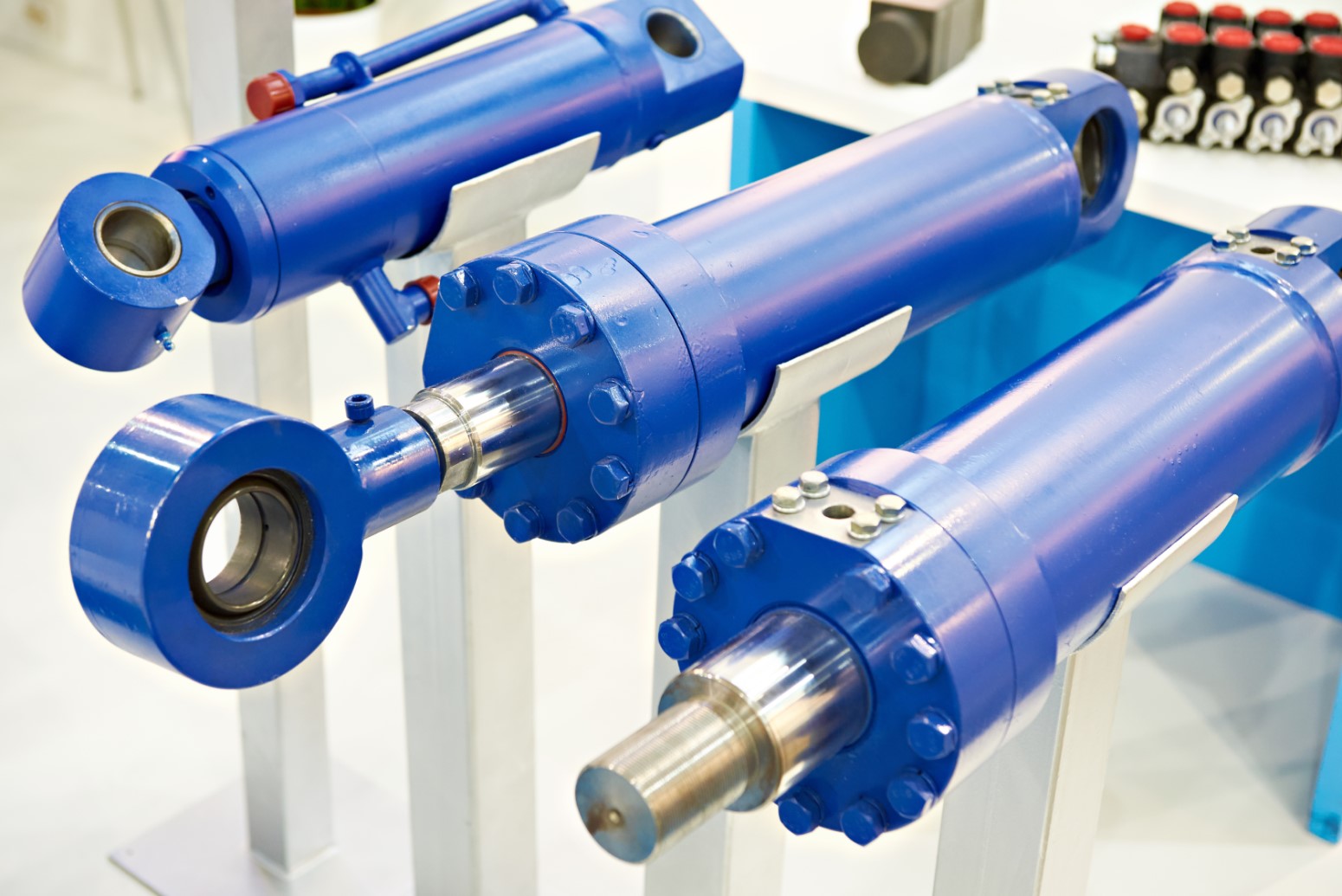

An Introduction To Hydraulic Cylinders Types And Selection вђ Artofit The three most common hydraulic piston configurations are ram style, tie rod, and welded. tie rod cylinders use strong, threaded steel rods on the outside of the cylinder to enhance stability. welded cylinders feature a robust housing with the barrel welded directly to the end caps, eliminating the need for tie rods. A hydraulic cylinder is a hydraulic actuator that transforms hydraulic energy into mechanical energy, performing linear reciprocating motions (or oscillating movements). its structure is simple, and its operation is reliable. when it is used to perform reciprocating motions, it can eliminate the need for deceleration devices, and there is no. Tie rod hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel. they are held together by four or more threaded tie bolts that run the length of the entire cylinder tube. these bolts hold the baseplate and head together. they usually have static seals to prevent leakage between the barrel and. 3. construction: hydraulic cylinders are utilized in heavy machinery such as excavators, bulldozers, and cranes for lifting and movement capabilities. 4. manufacturing: hydraulic cylinders are used in manufacturing and industrial applications to provide linear force for assembly, automation, and production line processes.

Comments are closed.