Bga返修台 X Ray点料机 X Ray检测设备 Bga拆焊台 Bga焊台 Xray检测设备

備審自我介紹範例 備審資料撰寫錦囊 Utvos Jesuisphoenix High magnification for bga x ray inspection. achieve exceptional image quality with jewelbox 70t for laboratory and failure analysis. featuring a 10 micron microtech™ x ray source, it offers magnification from 7x to 2000x and remarkable resolution of 100 line pairs mm. Aug 16,2024. as one of the leading professional suppliers of bga rework station, x ray inspection machine, and x ray smd reel counter in china, seamark has specialized in research, development, production, and sells for more than 10 years. certification: iso 9001:2000, rohs, ce, fda. choose us now.

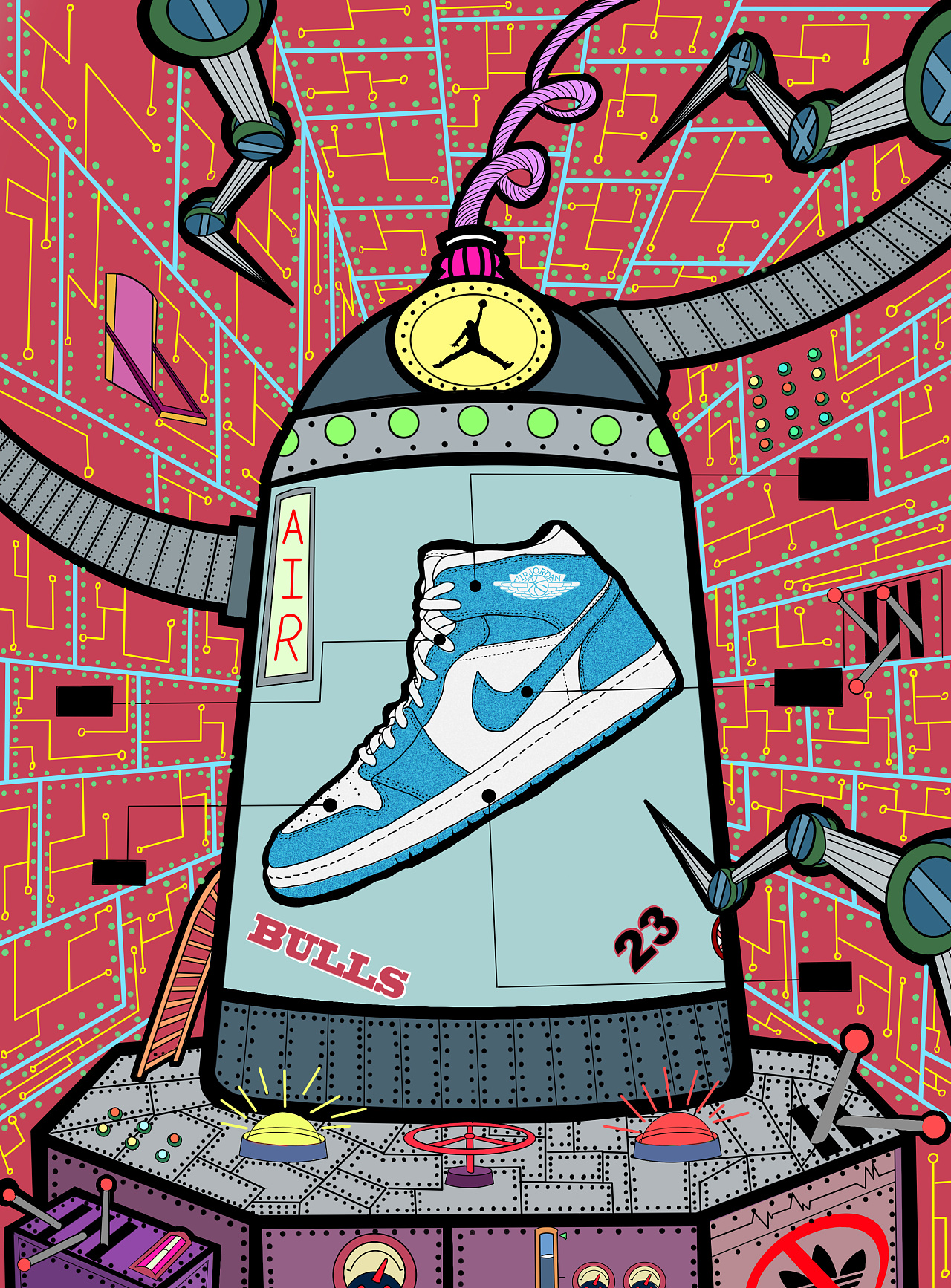

Aj1 插画 其他插画 Ctr1z 原创作品 站酷 Zcool Free Hot Nude Porn Pic Gallery Conclusions. modern 2d 3d x ray inspection systems are powerful tools for finding defects in bga, qfn and 3d packages and also provide fast and straightforward method for identifying counterfeit components. during the last several years, significant advancements in the x ray technology including sealed transmissive x ray sources, extremely high. 深圳市鼎华科技发展有限公司是一家集研发、生产、销售、服务于一体的国家级高新技术企业!. 是专业bga返修台、bga 焊台、x ray无损探伤检测设备 x ray 点料机、自动植球机等 smt 周边设备、非标自动化系统方案和工业装备提供商!. 公司以“研发为基础、品质为. Currently, bga soldering quality detection methods are very limited. common detection methods include: vision inspection, flying needle electron testing, x ray detection, dyeing detection and section detection. among them, dyeing and section detection are destructive detection, which can be used as failure analysis methods and are not suitable. Off axis compound angle capability with the gen x series systems can check for proper solder ball reflow by inspecting and measuring shape and size of the bga ball joints. sample x ray image of non eutectic solder ball and its attachments to the bottom board pad and top component joint. example of oblique angle image of bga solder ball joints.

推甄 攻略 04讀書 計畫 理工科系適用 Jesuisphoenix Currently, bga soldering quality detection methods are very limited. common detection methods include: vision inspection, flying needle electron testing, x ray detection, dyeing detection and section detection. among them, dyeing and section detection are destructive detection, which can be used as failure analysis methods and are not suitable. Off axis compound angle capability with the gen x series systems can check for proper solder ball reflow by inspecting and measuring shape and size of the bga ball joints. sample x ray image of non eutectic solder ball and its attachments to the bottom board pad and top component joint. example of oblique angle image of bga solder ball joints. Best's bga x ray inspection capabilities are shown as one of the x ray techs "drives around" the bga after bga rework. during bga x ray inspection the first. When a bga is installed on a circuit board in a factory, it is visually checked for proper alignment. if it passes this simple test some might assume all is.

數位帳戶 推薦 理財板 Dcard Jesuisphoenix Best's bga x ray inspection capabilities are shown as one of the x ray techs "drives around" the bga after bga rework. during bga x ray inspection the first. When a bga is installed on a circuit board in a factory, it is visually checked for proper alignment. if it passes this simple test some might assume all is.

アンジェリーナ ダニロヴァさんのインスタグラム写真 アンジェリーナ ダニロヴァinstagram Spill The Tea 2

Comments are closed.