Built Up Wood Beam Construction

How To Build Wooden Beams Image To U The bottom line, though, is that if all the pieces deflect together and equally, the beam should perform as designed. at a minimum, i recommend pairs of 16d nails every 12 inches along the beam, with the top row of nails 1 1 2 inches or so from the top of the beam, and the bottom row 1 1 2 inches or so up from the bottom. use the same nailing. How to build a three ply laminated 2x10 beam and what fasteners to use. by patrick. (long island, ny) i am building a ground level deck (max 24" of the ground). it is l shaped and will have 2 long beams (27.5' and 31'). the beams will be 3 ply pt sp#2 2x12's using 12' long lumber cut to fit the distances between the supporting posts.

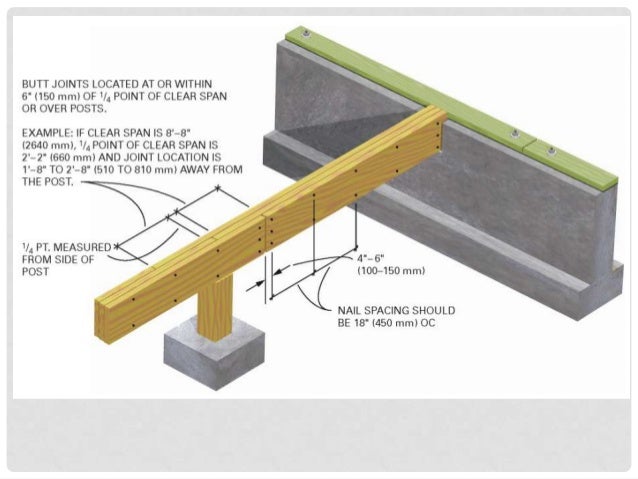

Built Up Wood Beam Construction Youtube Construction details for a 4 ply built up beam according to the ontario (canada) building code. Note how the beam sags near the centers of the spans, while the deflection curve turns upward over the post. the points where the curvature of the beam transitions from concave down over the post to concave up between the posts are the inflection points. at those points, stresses in the wood due to bending are lowest — in fact, they are zero. Built up beams are not as strong as laminated, steel or flitch beams (a steel plate sandwiched between two boards). but built up beams can be extended to span almost any distance and are the least expensive in terms of materials. the simplest type of built up beam can be constructed by following three easy steps. step 1 cut the individual boards. To compare built up wood beams, i multiply beam width by beam depth squared, and then i divide the product by 6. a triple 2×10 beam has a bending resistance factor of 64.2; add plywood between the 2x10s, and the factor increases 15% to 73.7. a beam of four 2x10s and no plywood has 18% more bending resistance than three 2x10s with plywood, but.

Built Up Wood Beams Built up beams are not as strong as laminated, steel or flitch beams (a steel plate sandwiched between two boards). but built up beams can be extended to span almost any distance and are the least expensive in terms of materials. the simplest type of built up beam can be constructed by following three easy steps. step 1 cut the individual boards. To compare built up wood beams, i multiply beam width by beam depth squared, and then i divide the product by 6. a triple 2×10 beam has a bending resistance factor of 64.2; add plywood between the 2x10s, and the factor increases 15% to 73.7. a beam of four 2x10s and no plywood has 18% more bending resistance than three 2x10s with plywood, but. In the simplest terms, a built up center beam provides a straight, level surface that supports the floor joists between the walls of the foundation. like most, the beam we installed for the project in this article was even with the mudsills and was carried by columns set on footings at regular intervals. a built up beam is made of several. Consideration of how a beam will be loaded and how the beam will be braced by the surrounding structure will help determine the appropriate product for the application. if you should have questions on your next design, feel free to contact our technical support team at 888 453 8358 or email techsupport@weyerhaeuser .

Comments are closed.