Ccporter Cu Cccable Cu Cccompressor Cu Ccpressure Cu Ccswitch Cu Fix Y Nyoauaeyan Yeyua Ccyoutube C

Porter Cable Air Compressor Parts Diagram Direct cu to cu bonding was achieved at temperatures of 150–250 °c using a compressive stress of 100 psi (0.69 mpa) held for 10–60 min at 10−3 torr. the key controlling parameter for direct. Further, when compared with a control sample in which ccs was incubated with cu to determine stoichiometry, we detected a reduction in ccs cu binding from typical 1:1 to either 0.5 cu atoms or 0.2 cu atoms per protomer when incubated with mek1 in either the presence or absence of bcs, respectively (fig. 1, i and j).

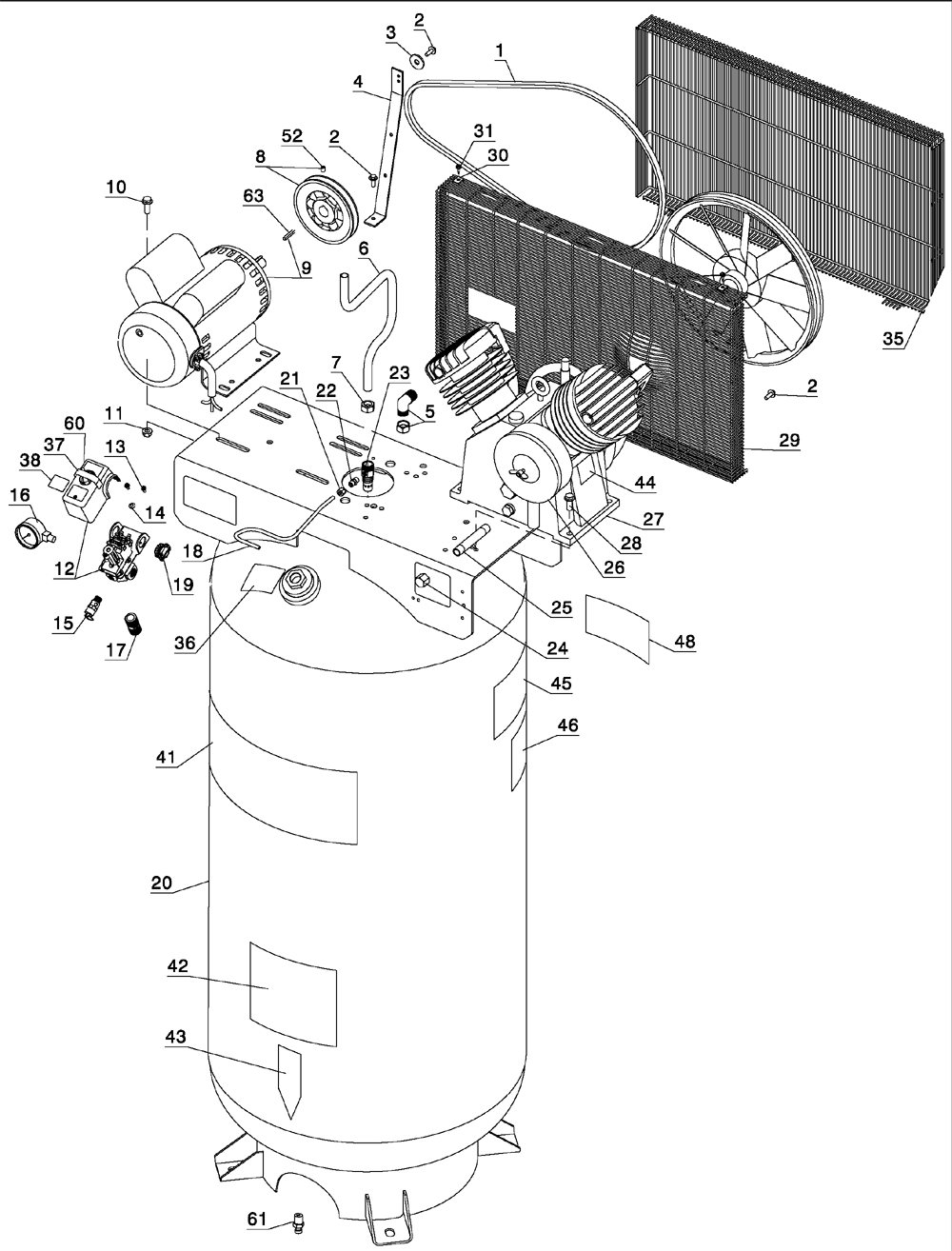

Porter Cable 60 Gallon Stationary Electric 135 Psi Vertical Air A reliable cu–cu bonding joint was achieved by using the highly sinterable cu nanoparticle paste. pure copper nanoparticles used in the preparation of nanoparticle paste were synthesized through simple routes, with an average size of 60.5 nm. under an ar h2 gas mixture atmosphere, the cu nanoparticle paste exhibited large areas of fusion after sintering at 300 °c and reached a low. Oil lubricated reciprocating compressors up to 480 bar (a) at work in the most demanding compressed air and gases applications, our cu gas compressors are a complete line of oil lubricated reciprocating compressors delivering high pressures up to 480 bar (a). cu heavy duty compressors, reliable compression for your high pressure gas applications. Moreover, the calculations are also done for cu and zno nps because their reduced size affects the thermodynamic calculations and the abundance of different cu surface sites. the formation of a cu zn bulk alloy by incorporation of zn atoms into cu nps can be described by reaction 1 or 2. zno (s) co = zn co 2. (1) zno (s) h 2 = zn h 2 o. Turn the regulator counterclock wise and set the outlet pressure to zero. remove the air tool or accessory. pull ring on safety valve allowing air to bleed from the tank until tank pressure is approximately 20 psi. release safety valve ring. drain water from air tank by open ing drain valve on bottom of tank.

Porter Cable C2002 Air Compressor Pressure Switch N003307s Moreover, the calculations are also done for cu and zno nps because their reduced size affects the thermodynamic calculations and the abundance of different cu surface sites. the formation of a cu zn bulk alloy by incorporation of zn atoms into cu nps can be described by reaction 1 or 2. zno (s) co = zn co 2. (1) zno (s) h 2 = zn h 2 o. Turn the regulator counterclock wise and set the outlet pressure to zero. remove the air tool or accessory. pull ring on safety valve allowing air to bleed from the tank until tank pressure is approximately 20 psi. release safety valve ring. drain water from air tank by open ing drain valve on bottom of tank. (a) lsv curves for c zif 8 1000, c–cu(oh) 2 @zif 8 10% 1000 and pt c in o 2 saturated 0.1 m koh solutions with a rotation speed of 1600 rpm and a sweep rate of 10 mv s −1; (b) percentage of peroxide and electron transfer numbers of c–cu(oh) 2 @zif 8 10% 1000 in o 2 saturated 0.1 m koh electrolyte; (c) polarization and corresponding power density curves of the primary zn–air battery. The cu–cu bonding performance of cu nanoparticle paste at 250 °c for different times was also studied, as shown in fig. 7. it can be seen that the sintered cu–cu joints maintain an average shear strength of more than 50 mpa after bonding for 1, 3, 5 min, indicating that sufficient diffusion of cu atoms has been basically achieved at this time.

Comments are closed.