Cfd Modeling For Grow Room Hvac Design

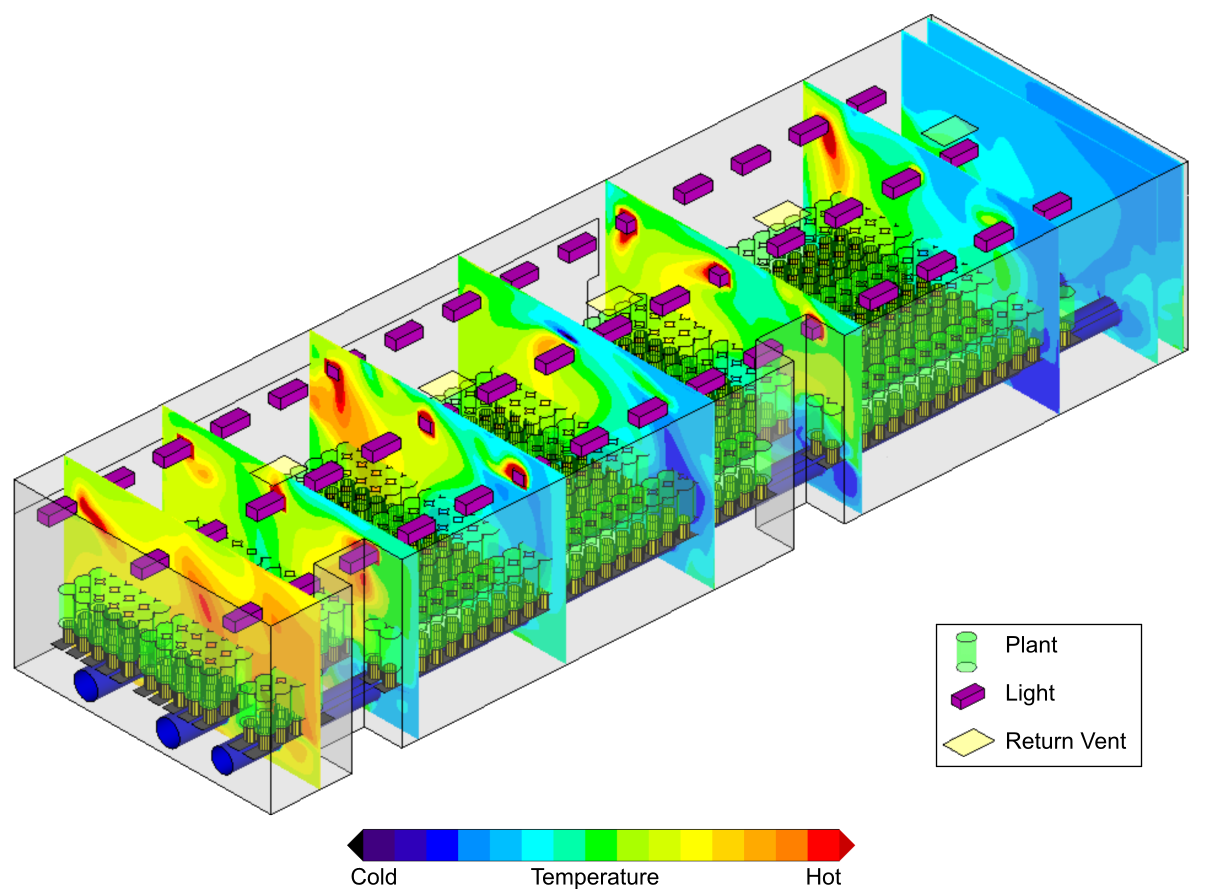

Cfd Modeling For Grow Room Environmental Control Azore Cfd Simulation Cfd modeling for grow room hvac design. a short video featuring dr. kevin linfield.this video is brought to you by airflow sciences corporation. for all yo. Cfd flow modeling of grow rooms or industrial warehouses is an effective tool for improving hvac systems and ventilation throughout the facility. cfd results can be used to develop an optimized, cost effective system that balances temperature and humidity profiles with minimal pressure losses and to confirm specification ranges for temperature or other attributes.

Case Study Grow Room Environmental Control Azore Cfd Simulation Software Therefore, 0.000035 kilograms. per second (0.000077 lb s) of water vapor is released to the grow room from the transpiration of each plant in the cfd mod el. setup. the supply air in the cfd model. Grow room environmental control. cfd flow modeling of grow rooms or industrial warehouses is an effective tool for improving hvac systems and ventilation throughout the facility. cfd results can be used to develop an optimized, cost effective system that balances temperature and humidity profiles with minimal pressure losses and to confirm. Cfd enables us to validate hvac designs before any components are purchased and installed. this technique optimizes grow room configurations by revealing any unobservable latent design problems, ultimately facilitating an optimized solution. cfd also enables systems designers to validate hvac designs before any components are purchased and. How to design grow room hvac in your cannabis cultivation facility. hvac impacts a wide variety of qualities in your cannabis grow house, including circulation, temperature, filtration humidity, and vapor pressure deficit. it can also help mitigate problems in the areas outside your facility, with noise and odor control measures.

Comments are closed.