Cold Welder Sampler Instructional Video

Andeli Tig Welder With Cold Welding Spot Welding Machines How to take crimped copper tube samples (dempsey lott and kevin cahill)© woods hole oceanographic institution. Cold welding vs. hot welding. welding in most processes involves the use of heat from either an electric arc, the flame of a torch, or a furnace to bring the base metal, filler metals, or wires to a molten state. with cold welding, since there is no heat, the metal is not heated to a molten state. there are many instances where the term “cold.

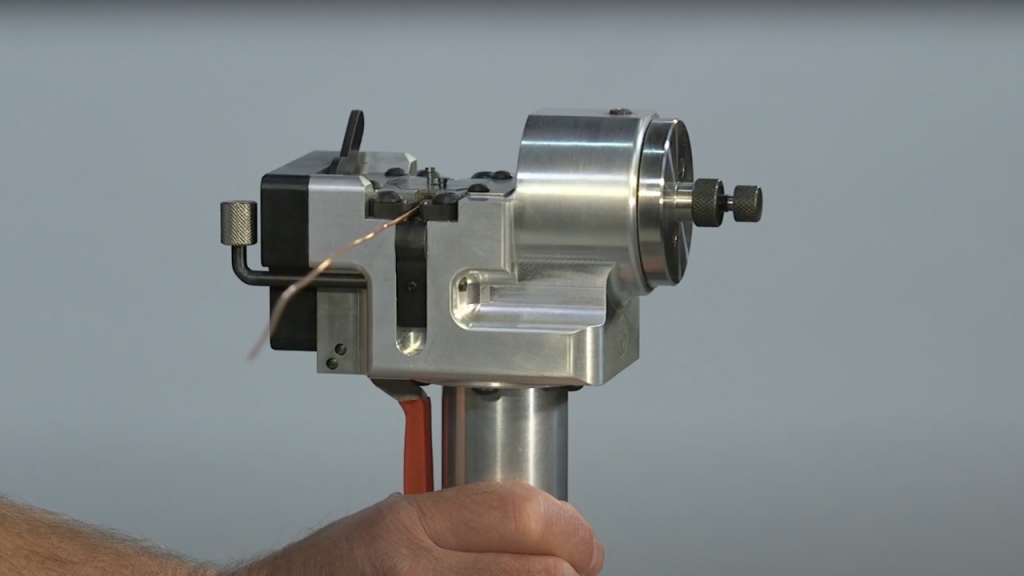

Best Cheap Cold Welding Machine For The Money I couldn't resist! once the so called "cold welding" videos went up, and everyone started messaging us about it, i had to go buy one to figure out what the r. The cold welding process requires no heat input to join metal pieces together. the metal remains in the solid phase, and it is not molten at any time. so, cold welding is considered to be a solid state welding process. instead, the energy necessary to bind the metal is applied in the form of pressure. The cold welding equipment. the equipment needed to take ~ 45 gram water samples in copper tubes is shown in the figures below. figure 1 shows the cold weld device used to seal the copper tubes. the cold weld is made by a hydraulically actuated crimper system (the jaws) activated by a foot pedal assembly shown in figure 2. Using a magnetic field to join parts together cold welding can be the most secure process and the fastest also.

Andeli Multi Function Welding Machine Mig Tig Pulse Mma And Cold The cold welding equipment. the equipment needed to take ~ 45 gram water samples in copper tubes is shown in the figures below. figure 1 shows the cold weld device used to seal the copper tubes. the cold weld is made by a hydraulically actuated crimper system (the jaws) activated by a foot pedal assembly shown in figure 2. Using a magnetic field to join parts together cold welding can be the most secure process and the fastest also. A cold weld is a weld defect in arc welding. it is also described as a lack of fusion. this is where the travel speed of the electrode is too slow. the weld starts to pile up and not fuse properly. the weld metal can also get in front of the arc while traveling. this is not related to the contact welding process. Cold welding is a solid state welding process that does not involve melting of metals. the two metal parts are joined together by pressing them together at high pressure. this is done by using a press to apply pressure to the two metals, which causes them to fuse together. cold welding is often used for repairs, as it is a quick and easy way to.

Cold Welding Explained What Is It How It Works A cold weld is a weld defect in arc welding. it is also described as a lack of fusion. this is where the travel speed of the electrode is too slow. the weld starts to pile up and not fuse properly. the weld metal can also get in front of the arc while traveling. this is not related to the contact welding process. Cold welding is a solid state welding process that does not involve melting of metals. the two metal parts are joined together by pressing them together at high pressure. this is done by using a press to apply pressure to the two metals, which causes them to fuse together. cold welding is often used for repairs, as it is a quick and easy way to.

Cold Welding Machine Metal Mold Repairing Machine

Comments are closed.