Comparing Single And Double Acting Hydraulic And Pneumatic Cylinder

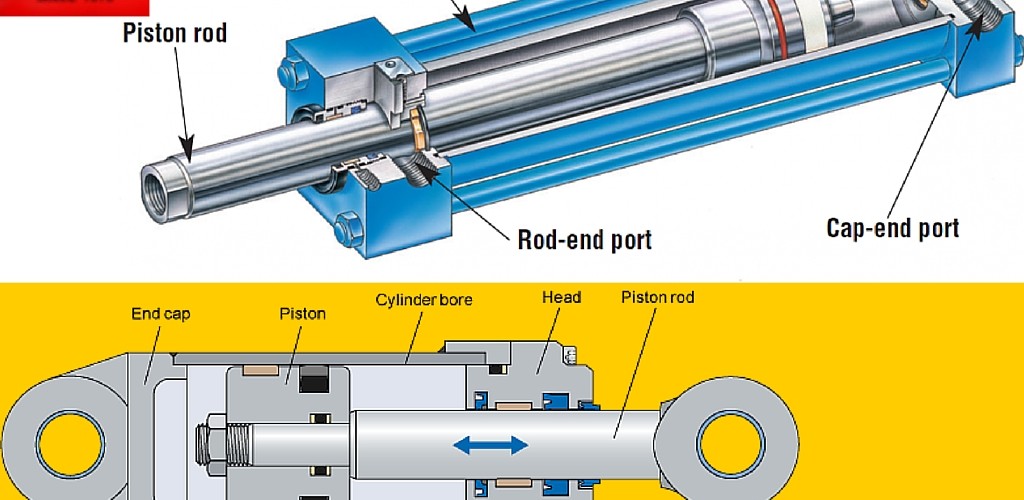

Comparing Single And Double Acting Hydraulic And Pneumatic Cylin Understanding the fundamental differences between single and double acting cylinders is essential for designing efficient systems. hydraulic cylinders (powered by fluid systems) are known for heavy lifting, while pneumatic cylinders (powered by air systems) are more cost effective and agile and are more widely used in industrial applications. 0. when comparing single acting vs double acting hydraulic cylinders, the most visible difference is the number of couplers or connection ports. a single acting hydraulic cylinder includes just one port. this is where the hydraulic fluid enters and forces the plunger out in one direction. a double acting cylinder includes two ports.

Single And Double Acting Hydraulic Cylinders Produced By Hydraulic Advantages of double acting cylinder. below are a few advantages of double acting cylinder: they use less energy while being faster and stronger. there is more movement control because the air moves two ways. they’re more likely to be iso compliant than single acting hydraulic cylinders. stroke and bore size variation. Usually, these external forces are spring force, diaphragm tension, gravity, etc. the spring recovery speed of the single acting cylinder is stable and is not affected by changes in air pressure. single acting is more functional than double acting. the single acting cylinder functions reliably and stably. the medium can only be pushed in one. Potential for leaks: the presence of more seals and connection points in double acting cylinders heightens the risk of hydraulic fluid leaks in comparison to single acting cylinders. reduced retraction force : some designs feature a reduced effective piston area on the rod side, resulting in less force available during retraction than during. When it comes to choosing the right hydraulic cylinder for your specific needs, one key decision you’ll need to make is whether to go with a single acting or double acting cylinder. in this blog post, we’ll compare single acting and double acting hydraulic cylinders, outlining their differences, advantages, and limitations to help you.

Comments are closed.