Conversion Of Ethylbenzene To Styrene In The Presence Of Steam

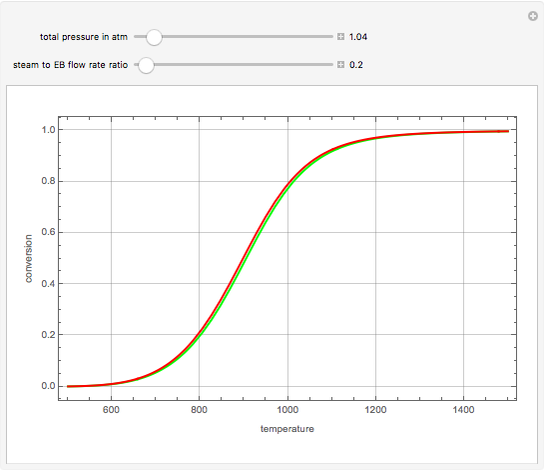

Conversion Of Ethylbenzene To Styrene In The Presence Of Steam Conversion of ethylbenzene to styrene in the presence of steam. t o t a l p r e s s u r e i n a t m. 1. 3 7. Dehydrogenation of ethylbenzene is carried out in the presence of steam, which has a threefold role: 1) it lowers the partial pressure of ethylbenzene, shifting the equilibrium toward styrene and minimizing the loss to thermal cracking 2) it supplies the necessary heat of reaction.

Conversion Of Ethylbenzene To Styrene In The Presence Of Steam Demonstrations.wolfram conversionofethylbenzenetostyreneinthepresenceofsteamthe wolfram demonstrations project contains thousands of free interact. An increase in the steam to ethylbenzene ratio means a decrease in the feed rate (f1) keeping the stem rate (f2) constant, figure 5 shows that when the steam to ethylbenzene ratio was increased. A particular emphasis is given to the preparation of styrene from ethylbenzene dehydrogenation using co 2 as a soft oxidant because this method consumes co 2 (one of the greenhouse gases) and emerges as a green chemistry process. the detailed mechanism of ethylbenzene dehydrogenation into styrene using co 2 is studied. The paper deals with conceptual design and simulation of an energy efficient process for manufacturing styrene by ethylbenzene dehydrogenation in adiabatic reactors using superheated steam as inert. a high performance catalyst is employed with selectivity of 95% at conversion of 70%. an innovative solution leads to a spectacular energy saving. the idea is running the steam generation under.

Conversion Of Ethylbenzene To Styrene In The Presence Of Steam Youtube A particular emphasis is given to the preparation of styrene from ethylbenzene dehydrogenation using co 2 as a soft oxidant because this method consumes co 2 (one of the greenhouse gases) and emerges as a green chemistry process. the detailed mechanism of ethylbenzene dehydrogenation into styrene using co 2 is studied. The paper deals with conceptual design and simulation of an energy efficient process for manufacturing styrene by ethylbenzene dehydrogenation in adiabatic reactors using superheated steam as inert. a high performance catalyst is employed with selectivity of 95% at conversion of 70%. an innovative solution leads to a spectacular energy saving. the idea is running the steam generation under. Steam is mixed with the ethylbenzene (eb) fed to the reactors to lower the partial pressure of ethylbenzene and increase conversion. there are also several other side reactions that produce undesirable byproducts (benzene, toluene, ethylene and carbon dioxide), whose reaction rates increase with temperature and partial pressures. The effect of temperature and pressure on the ethylbenzene equilibrium conversion [14]. (reproduced with permission) an excess of superheated steam of 720°c is added with steam:eb molar ratios of 6 13:1 for the styrene production before entering the dehydrogenation reactor. main reasons are listed below:.

Comments are closed.