Cylinder Selection The Key To Better Hydraulic Systems

Pneumatic Cylinder Output Force Calculations Pneumatic Cylinder Bosch rexroth provides tips and insights into selecting hydraulic cylinders. in this how to video you will learn about the different types of cylinders (tie. Cylinder selection is key to better hydraulics. april 15, 2013 by admin. correctly choosing your actuator will save you money and headaches. there has been a lot of talk about efficiency in fluid power systems lately. both component manufacturers and system designers are focusing on cranking a few more percent out of their products, whether due.

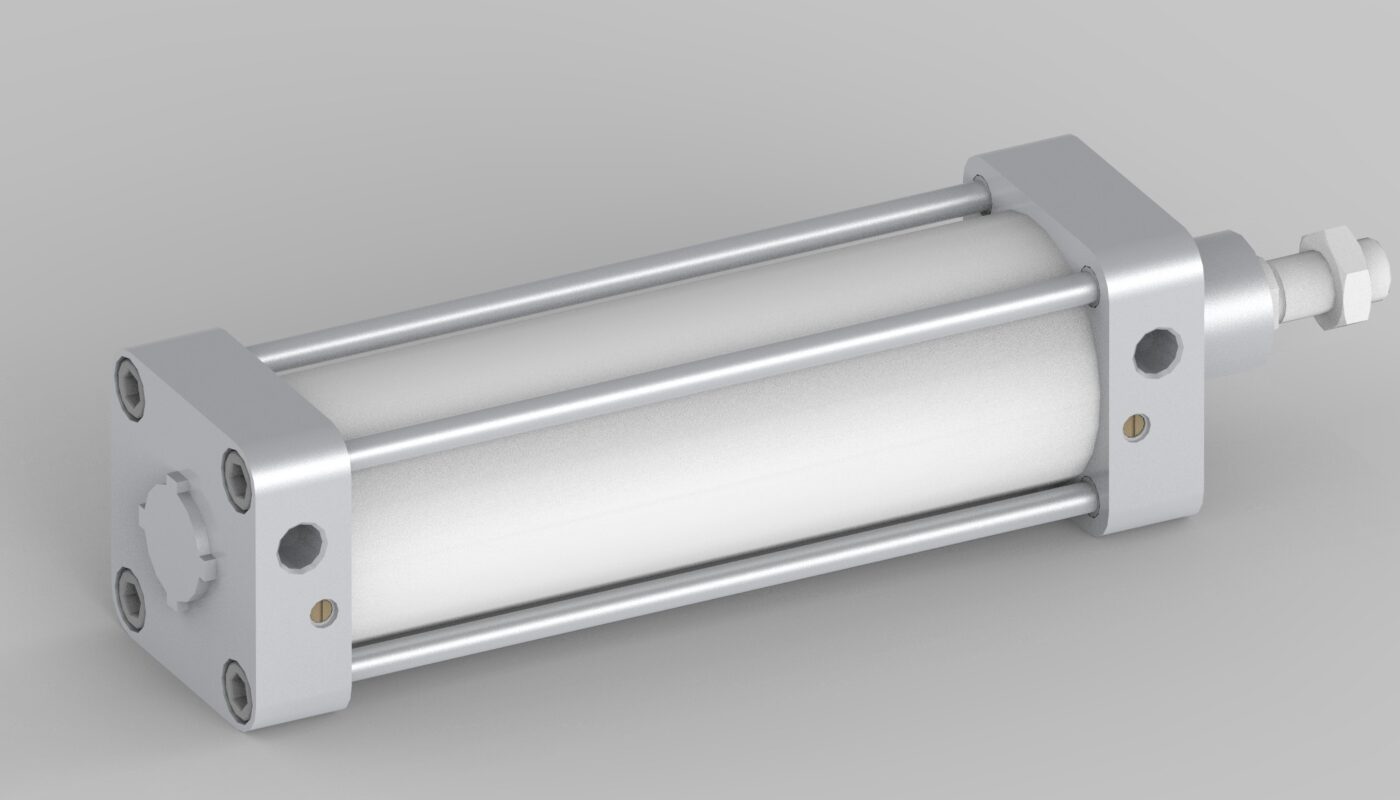

Filtertec Cuándo Es El Momento De Cambiar El Elemento Filtrante En Mi Style h (nfpa mf2) for mounting cylinders, the best practice is to use a mounting style that absorbs forces on the cylinder’s centerline. if the piston is rod is primarily loaded in tension. 4. welded cylinders. welded cylinders get their name from their end caps that are welded at the end of the barrel. the ports are also welded to the cylinder’s barrel. the rod gland at the front is threaded into the barrel cylinder. this provides an allowance for the rod assembly and seals to be easily removed. Selection considerations. 1. choose the right cylinder type. two basic hydraulic cylinder designs for industrial applications are tie rod and welded cylinders. tie rod cylinders use high strength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability. in the u.s., this is the most common cylinder type. Selection considerations. 1. choose the right cylinder type. two basic hydraulic cylinder designs for industrial applications are tie rod and welded cylinders. tie rod cylinders use high strength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability. in the u.s., this is the most common cylinder type.

Cylinder Selection The Key To Better Hydraulic Systems Youtube Selection considerations. 1. choose the right cylinder type. two basic hydraulic cylinder designs for industrial applications are tie rod and welded cylinders. tie rod cylinders use high strength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability. in the u.s., this is the most common cylinder type. Selection considerations. 1. choose the right cylinder type. two basic hydraulic cylinder designs for industrial applications are tie rod and welded cylinders. tie rod cylinders use high strength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability. in the u.s., this is the most common cylinder type. Our hydraulic cylinders are made in the usa and built to last. contact us or call our hydraulic cylinder experts at 1 866 817 9958 to request a quote and get the hydraulic cylinder you need fast. learn what factors to consider when choosing the right hydraulic cylinder. factors to consider include cylinder type, size, and operating environment. Each hydraulic cylinder is built to lift a certain capacity. there are general purpose designs, which are your “basic” options, and also high tonnage cylinders that have a capacity of up to 1000 tons. like cylinder stroke, the 80% rule also applies to tonnage. manufacturers always list their maximum weight capacity as a safe limit.

Comments are closed.