Difference Between Single Acting And Double Acting Hydraulicо

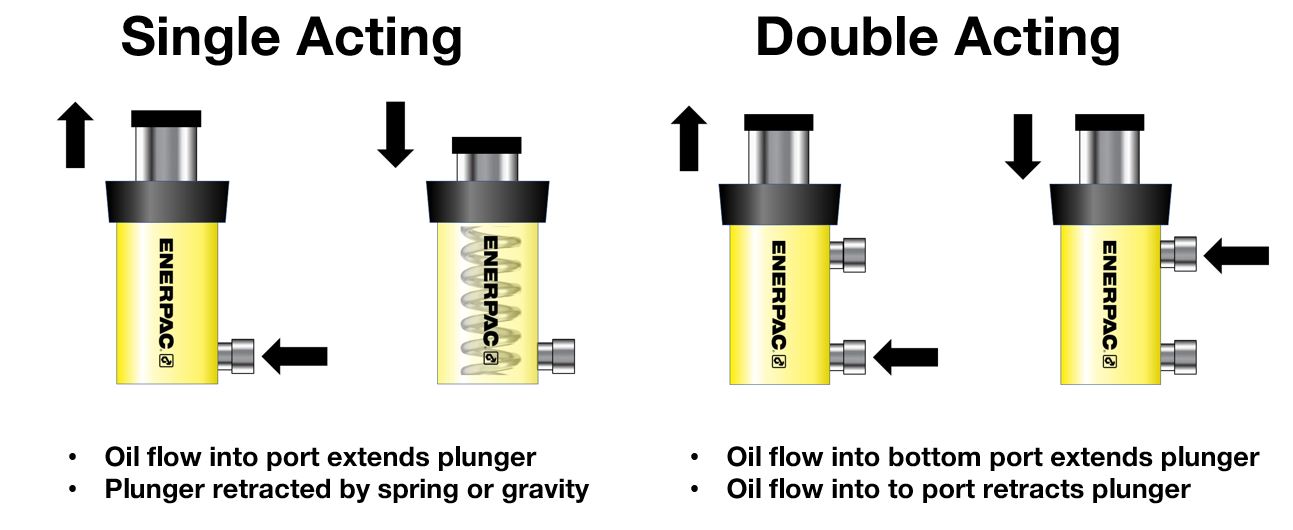

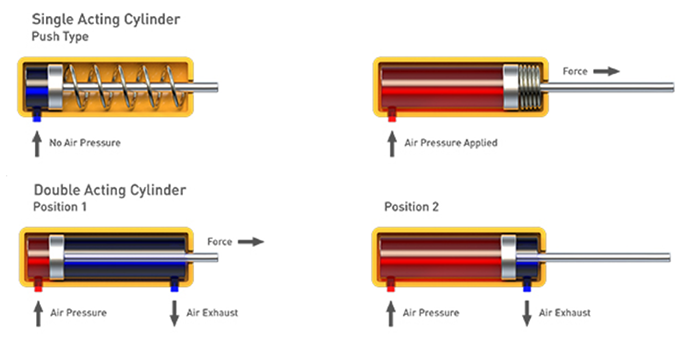

Single Acting Vs Double Acting Hydraulic Cylinders Enerpac Blog 0. when comparing single acting vs double acting hydraulic cylinders, the most visible difference is the number of couplers or connection ports. a single acting hydraulic cylinder includes just one port. this is where the hydraulic fluid enters and forces the plunger out in one direction. a double acting cylinder includes two ports. Single acting vs double acting cylinder: differences in work. when considering a single acting vs double acting cylinder, their function and purpose play the biggest role. the single acting cylinder function is simple, moving in one direction due to a force applied by compressed air or a plunger. it moves back using a spring or even just gravity.

How Can You Achieve Cylinder Flow Reduction Single acting cylinders have power up and gravity down capabilities, whereas double acting cylinders have power up and power down options. two directional power provides double acting cylinders more control and versatility. double acting cylinders offer more precise stroke movements and increased flexibility. Single acting vs. double acting . single acting cylinders are economical and the simplest design. hydraulic fluid enters through a port at one end of the cylinder, which extends the rod by means of area difference. an external force, internal retraction spring or gravity returns the piston rod. Double acting cylinders offer greater complexity. unlike single acting cylinders, they can transfer hydraulic fluids or output forces in extending and retracting directions. in addition, double acting cylinders can cater to more unique industrial systems, thanks to their pressing and pulling power without the aid of external power sources. The main difference between single and double acting hydraulic cylinders is that a double acting hydraulic cylinder uses hydraulic pressure to move a piston in two directions, while a single acting hydraulic cylinder relies on a spring or gravity to return to its original position. to help outline the differences in these fairly similar.

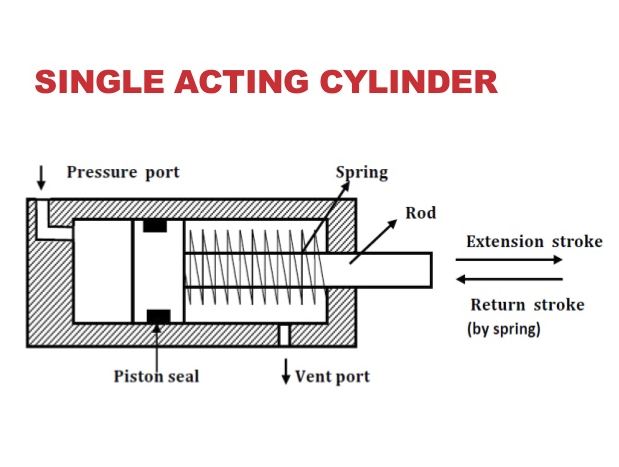

What Are Single Acting Double Acting Hydraulic Cylinders By Vcomp Double acting cylinders offer greater complexity. unlike single acting cylinders, they can transfer hydraulic fluids or output forces in extending and retracting directions. in addition, double acting cylinders can cater to more unique industrial systems, thanks to their pressing and pulling power without the aid of external power sources. The main difference between single and double acting hydraulic cylinders is that a double acting hydraulic cylinder uses hydraulic pressure to move a piston in two directions, while a single acting hydraulic cylinder relies on a spring or gravity to return to its original position. to help outline the differences in these fairly similar. Single acting vs. double acting cylinders single acting hydraulic cylinders. definition: a single acting hydraulic cylinder operates with hydraulic fluid pressure applied to one side of the piston, creating movement in one direction only. the return movement is achieved through an external force, such as a spring, gravity, or load weight. key. In contrast, a single acting cylinder has an a port for running the piston down by pressure from the pump but is retracted with an internal spring. see the image below as an example. a double acting cylinder has pressing and pulling power and is generally controlled with a joy stick control. a single acting cylinder only has pressing power.

Whats The Difference Between Single Acting And Double Acting Hyd Single acting vs. double acting cylinders single acting hydraulic cylinders. definition: a single acting hydraulic cylinder operates with hydraulic fluid pressure applied to one side of the piston, creating movement in one direction only. the return movement is achieved through an external force, such as a spring, gravity, or load weight. key. In contrast, a single acting cylinder has an a port for running the piston down by pressure from the pump but is retracted with an internal spring. see the image below as an example. a double acting cylinder has pressing and pulling power and is generally controlled with a joy stick control. a single acting cylinder only has pressing power.

Comments are closed.