Different Types Of Structural Steel Shapes Steel Shapes Structures

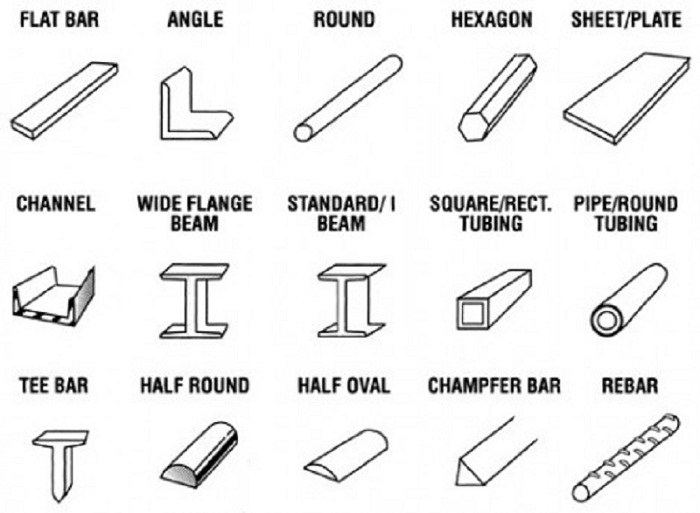

Steel Shapes And Sizes Ordinary steel includes round steel, square steel, flat steel, hexagonal steel, i beam steel, channel steel, equal and unequal angle steel, and threaded steel. according to size, these can be categorized into large, medium, and small types. a steel sheet with a thickness equal to or less than 4 millimeters. Broadly, structural steel is steel that is used in construction and architecture that usually comes in the form of elongated beams, piping, or channels. these shapes can be used to support the weight of a structure, in the ground to provide stability, strengthen materials like concrete, and more. structural steel is usually made from rolled.

Types Of Structural Steel Sections Advantages And Disadvantages Hollow structural section (hss) refers to high strength welded steel tubing. sometimes referred to as hollow steel sections, they are produced in round, square, and rectangular shapes that support multidirectional load bearing. as the name suggests, regardless of shape, the mid sections are hollow. tubes are a hollow steel shape that can be. Medium and high carbon structural steel requires from 0.31 to 1.50% carbon by weight, making this steel suitable for mechanical engineering applications. structural steel can also contain levels of manganese, phosphorus, sulfur, and silicone, among other materials. while manufacturers can add additional metals such as chromium, titanium, and. Here are some key physical properties of structural steel along with typical values: density, ρ: the density of structural steel is 7750 to 8100 kg m 3. young’s modulus of elasticity, e: typical values for structural steel range from 190 210 gpa. poission’s ratio: the acceptable value ranges from 0.27 to 0.3. Structural steel is a highly studied and widely used building material in construction, known for its predictable behavior. primarily made of carbon steel, it contains iron and up to 2.1% carbon, with higher carbon content increasing yield strength and reducing ductility. its main function is to reinforce structures, forming the skeletal.

Skoutaris Steel вђ Structural Steel Here are some key physical properties of structural steel along with typical values: density, ρ: the density of structural steel is 7750 to 8100 kg m 3. young’s modulus of elasticity, e: typical values for structural steel range from 190 210 gpa. poission’s ratio: the acceptable value ranges from 0.27 to 0.3. Structural steel is a highly studied and widely used building material in construction, known for its predictable behavior. primarily made of carbon steel, it contains iron and up to 2.1% carbon, with higher carbon content increasing yield strength and reducing ductility. its main function is to reinforce structures, forming the skeletal. Angles, or l shapes, are structural steel shapes characterized by their l shaped cross section. they consist of two legs of equal or unequal lengths, meeting at a 90 degree angle. angles are manufactured through hot rolling or cold forming, resulting in consistent dimensions and mechanical properties. typical applications of angles. The nomenclature for steel shapes follows two standards: for wide flange, bearing pile, s shapes, channels, and tees: the letter indicates the shape, the first number indicates the nominal height, and the second number indicates the weight per 1 foot of length. for instance, the w12x36 listed in the table below is a wide flange shape that has a.

Types Of Steel Structures Tension Members Compression Members Angles, or l shapes, are structural steel shapes characterized by their l shaped cross section. they consist of two legs of equal or unequal lengths, meeting at a 90 degree angle. angles are manufactured through hot rolling or cold forming, resulting in consistent dimensions and mechanical properties. typical applications of angles. The nomenclature for steel shapes follows two standards: for wide flange, bearing pile, s shapes, channels, and tees: the letter indicates the shape, the first number indicates the nominal height, and the second number indicates the weight per 1 foot of length. for instance, the w12x36 listed in the table below is a wide flange shape that has a.

Comments are closed.