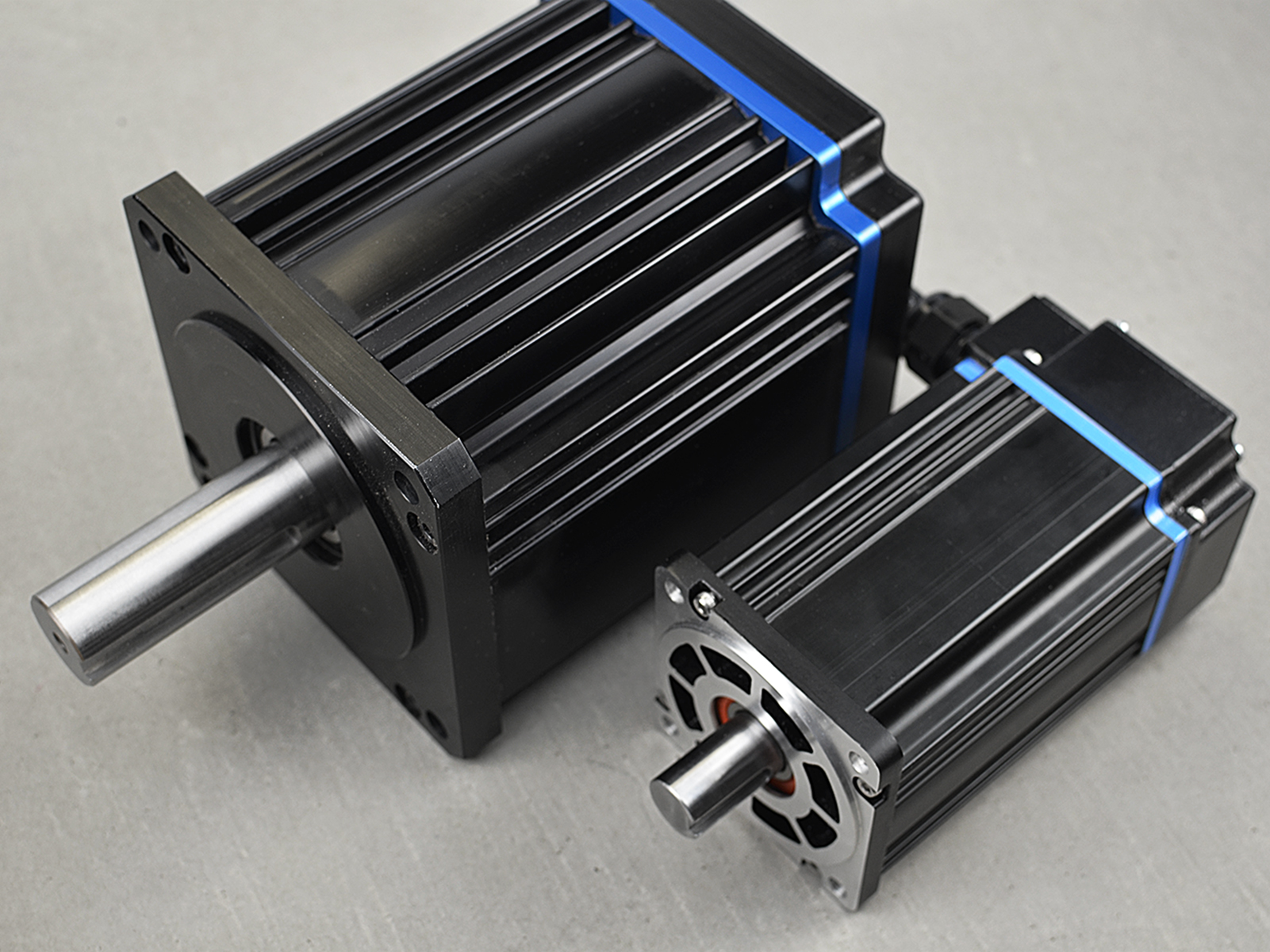

Direct Drive Motors

Direct Drive Motor Technology Reduces Energy Costs Several cars from the late 19th century used direct drive wheel hub motors, as did some concept cars in the early 2000s; however, most modern electric cars use inboard motor(s), where drive is transferred to the wheels, via the axles. [17] [18]. Direct drive motors refer to any linear or rotary motor that directly drives a load. these motors eliminate mechanical transmission components (like gearboxes and belts) to simplify the system, improve efficiency, and maximize lifetime. direct drive motors provide exceptional speed control and power for their size and weight and are suitable.

Components Roundup Direct Drive Motor Cybersecure Lvdt Signal Conditioner Direct drive motors are permanent magnet synchronous motors that drive the load directly without a transmission or gearbox. they are efficient, quiet, dynamic and suitable for high speed, acceleration and positioning applications. learn more about direct drive motors and their types by magnetic innovations. Energy conversion efficiency: direct drive motors are designed to convert electrical energy into mechanical energy with heightened efficiency. the absence of intermediary transmission components means there's less mechanical friction, leading to reduced energy losses. every watt of power supplied has a more direct impact on the motor's output. Direct drive motors also have lower noise production than conventional motors, which is important for noise sensitive applications, like those in the medical and laboratory industries. without additional transmission elements, direct drive motors tend to be more compact than traditional motors, making them easier to integrate into machines and systems with tight spaces. Direct drive motors operate in a manner largely similar to that of the majority of brushless dc motors. magnets are fixed to the motor's rotor, and windings are arranged on the motor's stator. as the windings are energized, they create electromagnetic fields which either attract or repel the rotor's magnets.

Direct Drive Motors Direct drive motors also have lower noise production than conventional motors, which is important for noise sensitive applications, like those in the medical and laboratory industries. without additional transmission elements, direct drive motors tend to be more compact than traditional motors, making them easier to integrate into machines and systems with tight spaces. Direct drive motors operate in a manner largely similar to that of the majority of brushless dc motors. magnets are fixed to the motor's rotor, and windings are arranged on the motor's stator. as the windings are energized, they create electromagnetic fields which either attract or repel the rotor's magnets. Direct drive – an engineer’s guide. direct drive has seen a re birth in awareness and new applications over the past 20 years. driving a shaft directly is really nothing new and has been done for over 100 years. what has changed is the types of motors used for the application and types of motor controllers that are available. Direct drive motors meet the high torque needs of large inertia rotary loads. increasing the pole count increases the rotor diameter, total flux, and torque moment arm which produces the higher.

Comments are closed.