Flexible Pin Clamping System Produces Form Fit The Fabricator

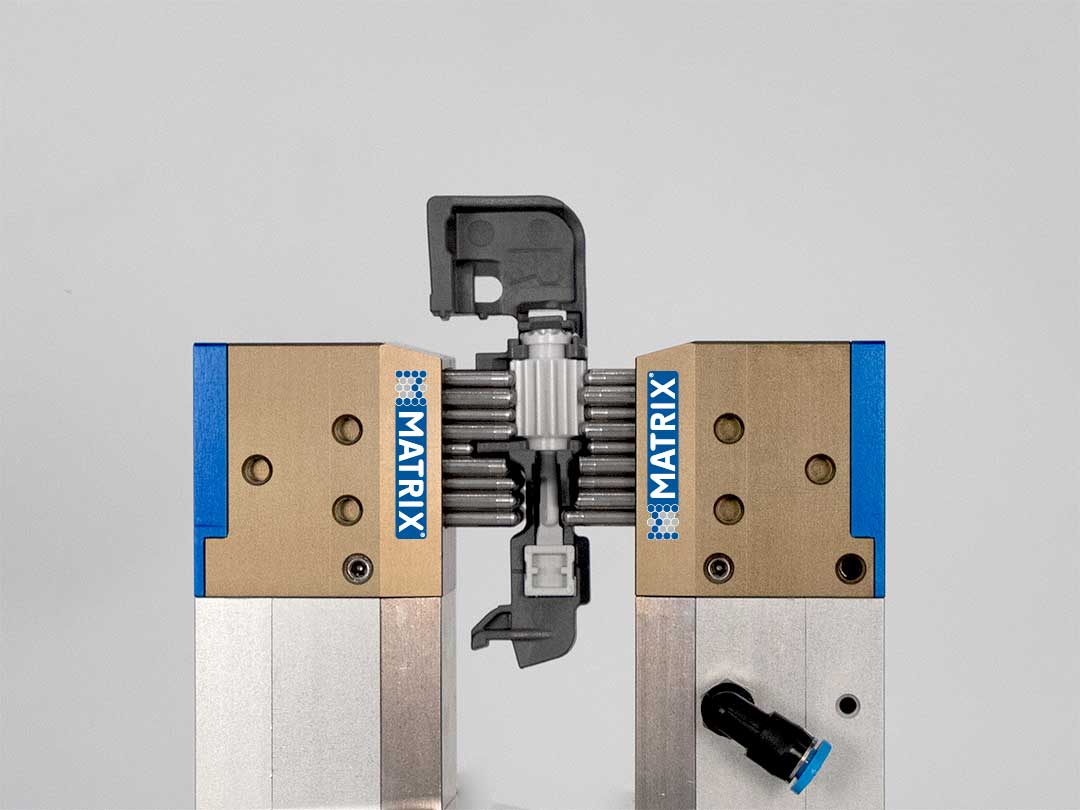

Flex Clamp ù ùïê Matrix Gmbh ççclamping çü Technology Flexible pin clamping system produces form fit. april 14, 2015. product release. machining. euro tech corp. offers the jaw flexible pin clamping element. within seconds, it molds a part specific outline, readying the workpiece for machining and inspection, the company reports. each pin is locked hydraulically by a separate internal clamping sleeve. The jaw clamping system. june 19, 2015. product release. management. euro tech corp. has released the jaw clamping system, which enables partspecific outline creation with a flexible pin clamping element. each pin is locked by a separate clamping sleeve. axial movable pins contact the part and generate a form fit between the element and the part.

Flexible Pin Clamping System Produces Form Fit The Fabricator The advantages of the matrix® clamping systems are perfectly obvious: an individual form fit, and a secure hold are 100% guaranteed even on tolerance affected surfaces. the flexible pins offer minimal clamping force on complex and sensitive workpieces. in the workflow, a matrix® device can be quickly and easily rearranged. Matrix clamping fixtures with flexible pins that adapt precisely to any shape. in a matter of seconds, you can safely and absolutely form fittingly fix, grip and clamp the most different workpieces. the set up of the machining and assembly system for parts with changed workpiece geometry, as well as a pallet and tool handling. June 22, 2015. menomonee falls, wisconsin – a part specific outline is molded within seconds with this new flexible pin clamping system, making your piece ready for machining, inspection, or numerous other applications. each pin is locked hydraulically using separate, internal kostyrka clamping sleeves with no axial or radial pin movement. 262 781 6777. fax. 262 781 2822. view website. send email. view buyers guide. april 01, 2015. within seconds, a part specific outline is molded with this new flexible pin clamping element from euro tech corp., making a workpiece ready for machining, inspection or numerous other applications; with each pin locked by a separate clamping sleeve.

Rhs Flexible Tooling Fixture 125x90x114 5mm June 22, 2015. menomonee falls, wisconsin – a part specific outline is molded within seconds with this new flexible pin clamping system, making your piece ready for machining, inspection, or numerous other applications. each pin is locked hydraulically using separate, internal kostyrka clamping sleeves with no axial or radial pin movement. 262 781 6777. fax. 262 781 2822. view website. send email. view buyers guide. april 01, 2015. within seconds, a part specific outline is molded with this new flexible pin clamping element from euro tech corp., making a workpiece ready for machining, inspection or numerous other applications; with each pin locked by a separate clamping sleeve. Ast & precise clamping. any geometry.the pin elements by kostyrka® provide fast and precise molding of the outline of the part. to be clamped into a clamping element. within seconds, a. art specific element is being created. axially movable pins contact the part and generate a for. fit between the element and the part. in this position the. The holder with the clamping pins and a the clamping force is achieved by turning a hand lever or allen wrench, the system remains virtually free of wear. pressure spots on the workpieces are non existent because of the form fit. the pins, which less steel and the modules are made of aluminum alloy. the result: a high degree.

Comments are closed.