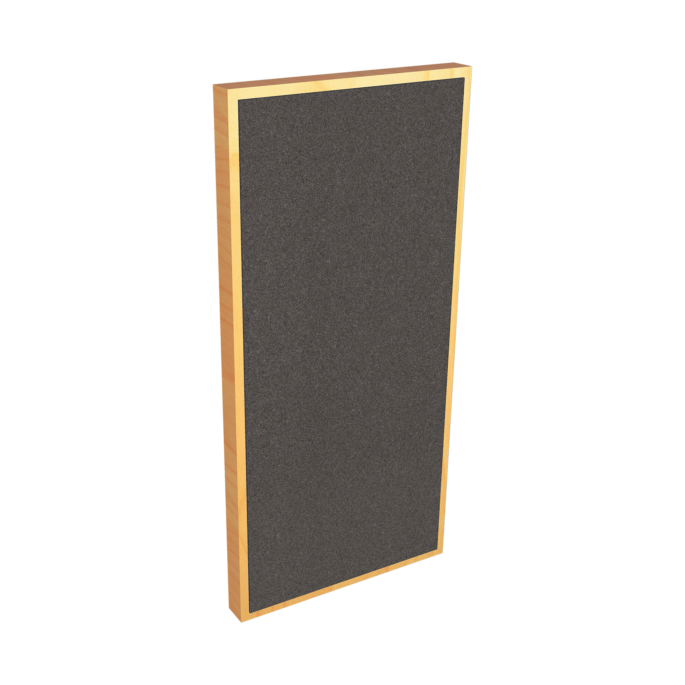

Foam Frame Panel Acoustic Treatment

Foam Frame Panel Acoustic Treatment Foam frame panel. $ 250.00 – $ 450.00. the most economical way to install our foam technology on your walls or ceiling is to use our foam and the mounts. this allows for airflow on both sides as the mount pushes the foam 2″ away from the surface to allow for air floor. foam and mounts are designed to work together. 4) mount your panels to the wall. there are an infinite number of ways to mount your panels to the wall, but will be limited by the way you build your frames. having a strip of wood across the back to hold in the treatment also gives you a surface to mount from if you want to use hooks or brackets.

Elgato Wave Panels Starter Set Black 6 Acoustic Treatment Panels They are commonly made from rigid fiberglass, mineral wool, acoustic foam, recycled cotton, or other absorbent materials. for most rooms, acoustic panels should cover 25 45% of the total wall surface area. bass traps are extra thick acoustic panels designed to absorb troublesome low frequency buildups, standing waves, and resonances. Acoustic foam, i.e. absorption, is a very popular method of acoustic treatment because it is both readily available and relatively inexpensive. this is great news! acoustic foam works by reducing the amount of sound energy within a room. the sound energy does not disappear, rather, it is converted into other forms of energy. Acoustic foam panels are measured based on their nrc, which stands for “noise reduction coefficient.”. this is how much of the ambient sound a panel can absorb. nrcs go from 0 to 1, with an nrc of 0 being an object that absorbs no sound and an object with an nrc of 1 being one that will absorb all sounds that hit it. Step 1: plan your build. having determined the surface area to cover, decide on the dimensions and number of panels you need. for a 10’x10’ room with an 8’ height, the wall surface is 320 ft² – 10% is 32 ft², 20% is 64 ft², and 35% is 112 ft². if using 2’x4’ (8 ft²) panels, you’ll need 4, 8 or 14 panels respectively.

Foam Frame Panel Acoustic Treatment Acoustic foam panels are measured based on their nrc, which stands for “noise reduction coefficient.”. this is how much of the ambient sound a panel can absorb. nrcs go from 0 to 1, with an nrc of 0 being an object that absorbs no sound and an object with an nrc of 1 being one that will absorb all sounds that hit it. Step 1: plan your build. having determined the surface area to cover, decide on the dimensions and number of panels you need. for a 10’x10’ room with an 8’ height, the wall surface is 320 ft² – 10% is 32 ft², 20% is 64 ft², and 35% is 112 ft². if using 2’x4’ (8 ft²) panels, you’ll need 4, 8 or 14 panels respectively. How to make an acoustic panel. acoustic panels can be made with basic diy skills. mineral wool is available in semi rigid 2 x 4 foot (or 600 x 1200mm) slabs. buy a four pack of around 45kg m3 density, 4 inch (or 100mm) thick. the slabs are actually fully functioning acoustic panels out of the box. but they’re delicate and need a frame around. A few of them include: acoustic foam panels: these are available in a range of sizes, thicknesses, and surface designs. they can be placed on walls and ceilings to help absorb sound. to maximize the effectiveness of your sound treatment, opt for thicker foam or surfaces such as wedge, pyramid, or eggcrate.

Comments are closed.