Have A Watch Of This Full Tube Bending Manufacturing Cell

Innovative Automated Tube Bending Cell Allows Wheelbarrow Manufacturer To find out more about how we can help your team, get in touch now.sales@unisonltd unisonltd make sure you subscribe to our channel.#tubebending #p. The tube form solutions blog. automated bending cells. automated tube fabrication manufacturing cells offer manufacturers increased productivity without increasing labor. automated bending cells also offer unparalleled repeatability, making them an often ideal solution for large volume production.

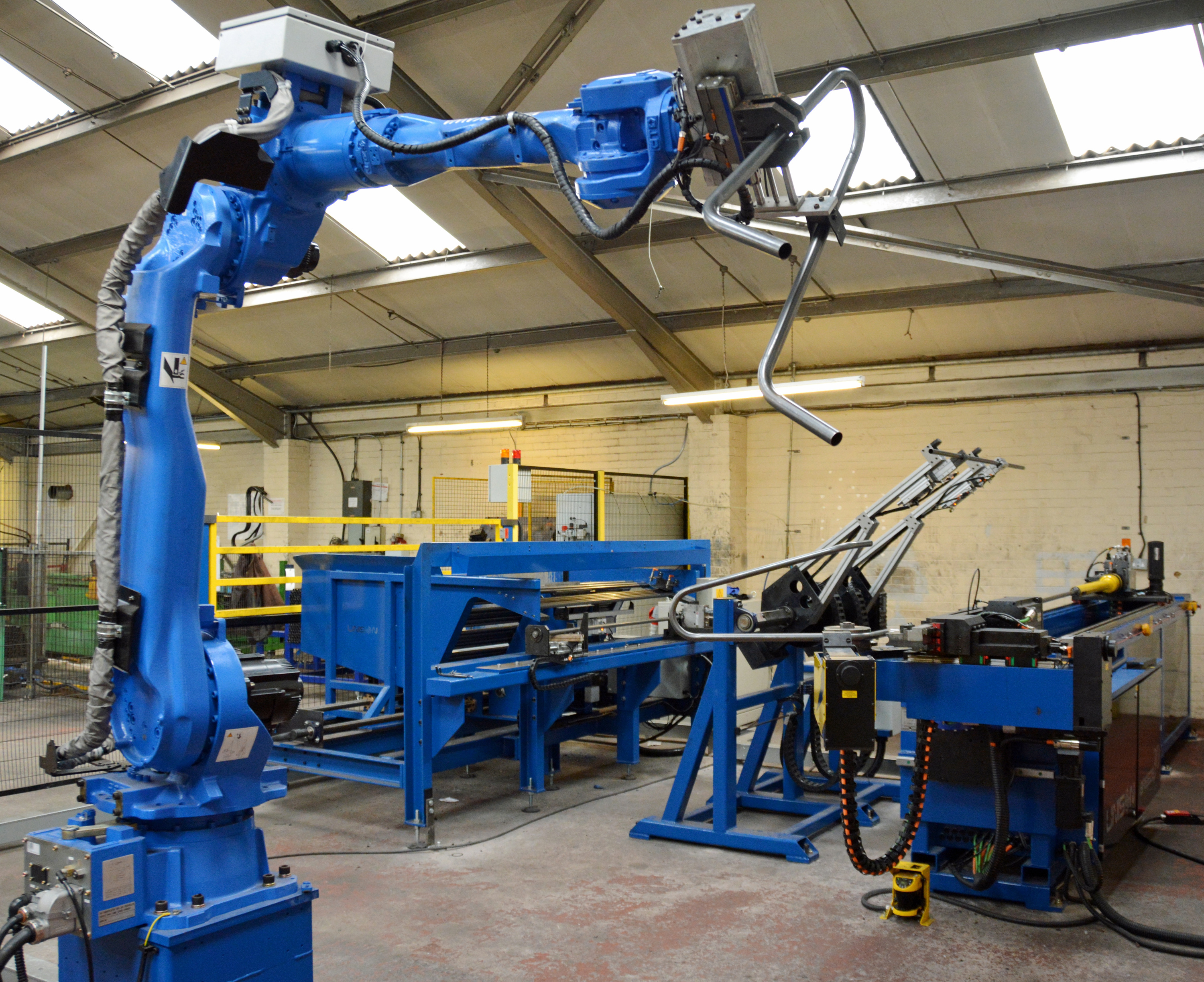

Miic T Win22l Cnc Robotic Tube Bending Cell Fh Machinery Inc Fully automated, efficient and reliable – our bending cells for series production. users who want a fully automated production process have the option of expanding any cnc bending machine to create a bending cell. a highly complex, fully automated bending cell gives you the advantage of a very consistent and reliable manufacturing process. Further information: trumpf en int products machines systems bending machines the video shows the fully automated trubend cell 5000 bending c. Fischer has made automation central at its factories worldwide. at two of its plants—waterloo (near toronto), ont., and manchester, tenn.—19 of the 20 tube bending machines in use are integrated into fully automated bending cells. thomas prell, vice president of the fischer group’s business in the u.s. and canada, can tell you why. The new production cell comprises a tube bundle loader, tube orientation station, intermediate dual arm loader, bending machine and a 5 axis articulated robotic handler. all five stages are controlled by a central pc. the tube bender is based on a customized 30 mm (1.25 inch) single stack all electric model from unison’s breeze range.

Csm Tube Bending Cell Quality Metal Products Blog Fischer has made automation central at its factories worldwide. at two of its plants—waterloo (near toronto), ont., and manchester, tenn.—19 of the 20 tube bending machines in use are integrated into fully automated bending cells. thomas prell, vice president of the fischer group’s business in the u.s. and canada, can tell you why. The new production cell comprises a tube bundle loader, tube orientation station, intermediate dual arm loader, bending machine and a 5 axis articulated robotic handler. all five stages are controlled by a central pc. the tube bender is based on a customized 30 mm (1.25 inch) single stack all electric model from unison’s breeze range. December 11, 2007. product release. bending and forming. unison has developed uni vercell, an automated tube bending cell suitable for high volume applications such as automotive. available in north america through horn machine tools, the cell is designed to provide a complete loading, end forming, bending, and vision inspection process in the. However, the cell is programmable and can also be configured for a variety of tube bending tasks to help handle peak production of other products. each barrow in a box frame comprises three separate parts (to facilitate compact packaging) and is fabricated from 30 mm diameter steel tubing in up to two metre lengths.

Csm Tube Bending Cell Quality Metal Products Blog December 11, 2007. product release. bending and forming. unison has developed uni vercell, an automated tube bending cell suitable for high volume applications such as automotive. available in north america through horn machine tools, the cell is designed to provide a complete loading, end forming, bending, and vision inspection process in the. However, the cell is programmable and can also be configured for a variety of tube bending tasks to help handle peak production of other products. each barrow in a box frame comprises three separate parts (to facilitate compact packaging) and is fabricated from 30 mm diameter steel tubing in up to two metre lengths.

High Tech Tube Bending Cell Hansa Flex Youtube

Comments are closed.