How A Industrial Pneumatic Systems Works And The Five Most Common Elements Used

Mastering Pneumatic Systems Guidelines For Success Automation A pneumatic system is a collection of interconnected components using compressed air to do work for automated equipment. examples can be found in industrial. Contact us today for your pneumatic system solutions at 281 394 7177 or sales us@airtac . in the intricate world of industrial automation, pneumatic systems serve as the silent force behind.

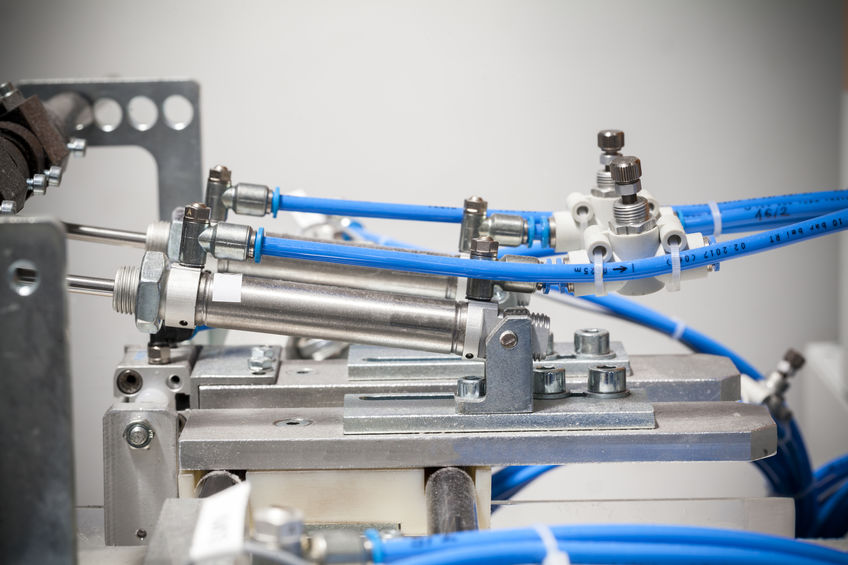

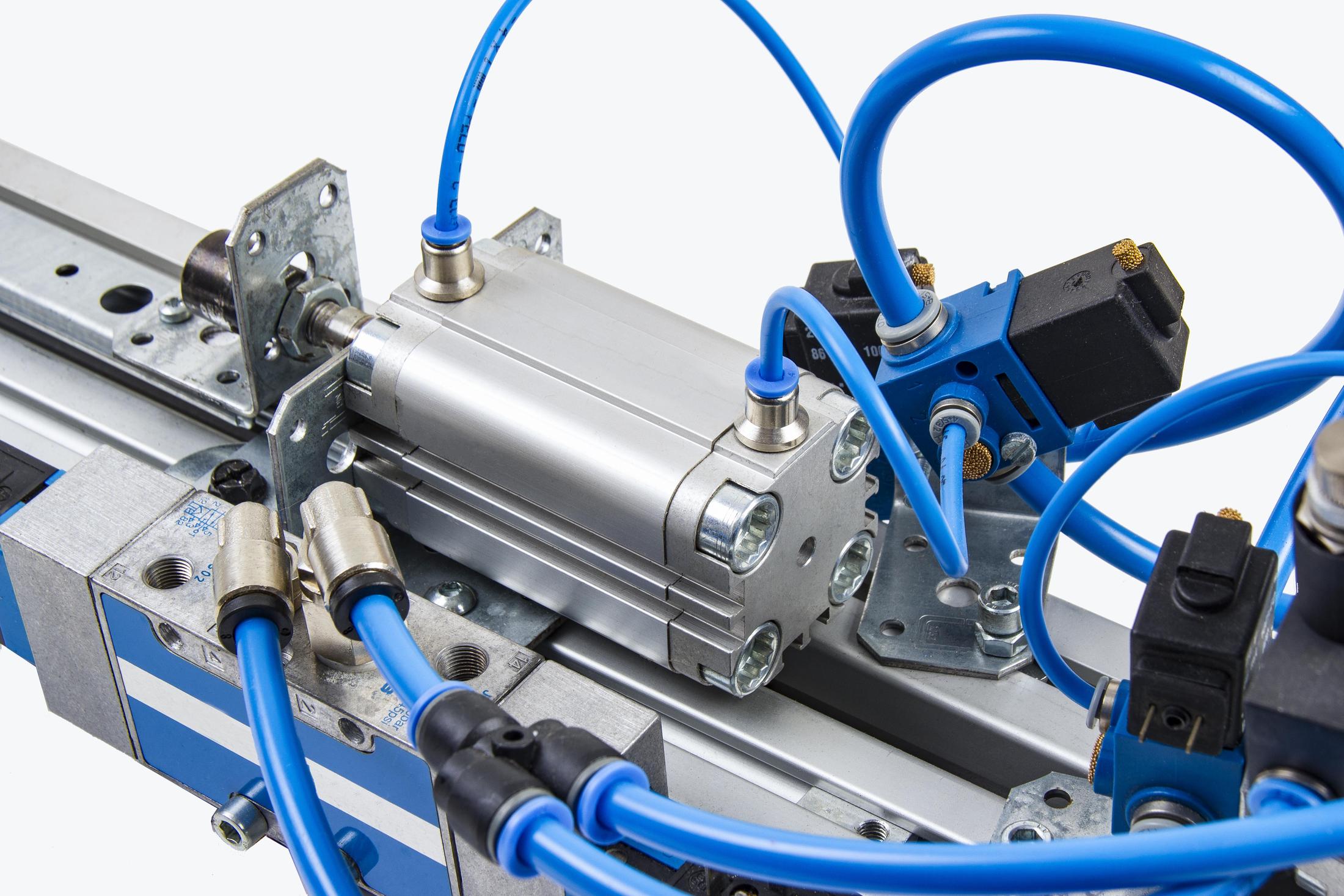

в How A Industrial Pneumatic Systems Works And The Five Most A pneumatic system is any system that uses pressurized gas (usually compressed air) to operate machinery or tools. the most common types of pneumatic systems are those used in industrial and manufacturing settings, but they can also be found in automotive and medical environments. pneumatic systems consist of five main components: an air source. The most important component in a pneumatic system is the air compressor. these draw in ambient air, compress it, and release it through the connected tubing at a required pressure. they function based on a driven motor engine. the device converts mechanical energy provided by the prime mover to the potential energy present in the compressed air. A pneumatic system utilizes air pressure to create mechanical motion. a basic pneumatic system consists of an intake filter that traps dirt before it enters the system, an air compressor that provides a source of compressed air, a dryer that removes the moisture in the air, a pressure tank that is a reservoir of compressed air, a pressure regulator that maintains air pressure, a valve that. A pneumatic system is a connection of various components such as (compressors, intercoolers, controllers, and actuators), that converts the pressure energy of compressed air into mechanical work. pneumatic systems are used where human strength and accuracy are not enough. nowadays pneumatic systems are widely used in various industries to.

Automation In Action 4 Real World Applications For Pneumatic Systems A pneumatic system utilizes air pressure to create mechanical motion. a basic pneumatic system consists of an intake filter that traps dirt before it enters the system, an air compressor that provides a source of compressed air, a dryer that removes the moisture in the air, a pressure tank that is a reservoir of compressed air, a pressure regulator that maintains air pressure, a valve that. A pneumatic system is a connection of various components such as (compressors, intercoolers, controllers, and actuators), that converts the pressure energy of compressed air into mechanical work. pneumatic systems are used where human strength and accuracy are not enough. nowadays pneumatic systems are widely used in various industries to. A pneumatic system is a collection of interconnected components using compressed air to do work for automated equipment. examples can be found in industrial manufacturing, a home garage or a dentist office. this work is produced in the form of linear or rotary motion. the compressed air or pressurized gas is usually filtered and dried to. 6 essential pneumatic components. while pneumatic systems rely on a variety of components, these six are integral to providing movement and control in industrial applications: air compressor: pneumatic systems rely on air compressors to draw in air from the surrounding atmosphere and compress it. as the air volume decreases, it becomes.

What Are The Basic Equipment Parts Of A Pneumatic System Spunky Sprout A pneumatic system is a collection of interconnected components using compressed air to do work for automated equipment. examples can be found in industrial manufacturing, a home garage or a dentist office. this work is produced in the form of linear or rotary motion. the compressed air or pressurized gas is usually filtered and dried to. 6 essential pneumatic components. while pneumatic systems rely on a variety of components, these six are integral to providing movement and control in industrial applications: air compressor: pneumatic systems rely on air compressors to draw in air from the surrounding atmosphere and compress it. as the air volume decreases, it becomes.

Products

Comments are closed.