How Do Hydraulic Cylinder Works

5 Signs Your Hydraulic Cylinder Has A Problem Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. these cylinders generate mechanical force in a linear motion for a variety of applications. they are typically used for pressing, pulling, pushing or lifting something that requires. This video explains the working mechanisms of a hydraulic cylinder with visualizations using 3d animations.

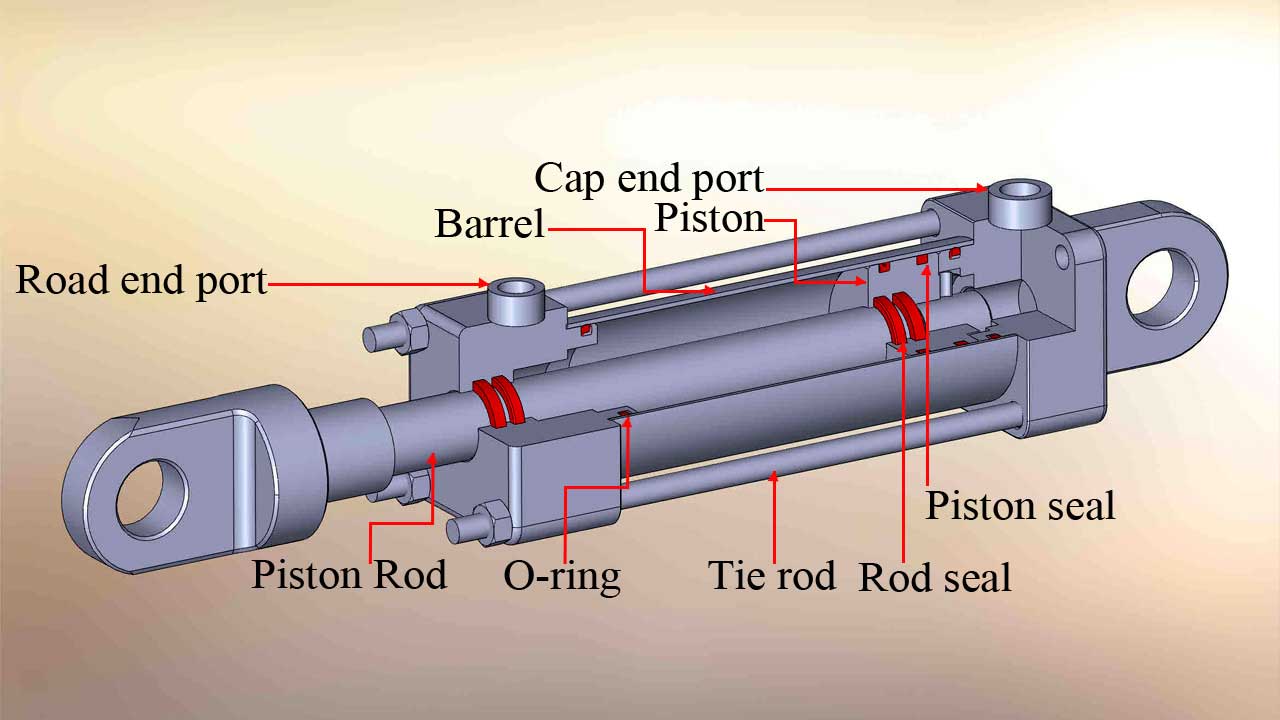

What Are The Parts Of A Hydraulic Cylinder Anbao Hydraulic Hydraulic cylinder design. construction and working principle of the hydraulic cylinder. components of the hydraulic cylinder: rod, piston, pipe, caps, seals. The hydraulic pressure acts on the piston to do linear work and motion. flanges, trunnions, and or clevises are mounted to the cylinder body. the piston rod also has mounting attachments to connect the hydraulic cylinder to the object or machine component that it is pushing. a hydraulic cylinder is the actuator or ‘motor’ side of the system. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. the barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. the piston has sliding rings and seals. 1. getting started: fueling the cylinder. the initial step in the working mechanism of a hydraulic cylinder is the introduction of hydraulic fluid. this fluid, typically oil, is pumped into the cylinder, which creates pressure. the presence of hydraulic fluid is essential for the transmission of force.

Comments are closed.