How To Be Safe While Welding

Welding Safety Tips And Guide For Beginners Welding Judge One welding operator can create 40 grams of airborne fume per hour. the airborne welding fume is a mix of gases and tiny particles that can penetrate our lungs. and while most welding fumes are odorless, they are still dangerous. using a fire resistant suit. using a fire resistant suit in a welding safety program is a must have item. In order to eliminate or reduce the most common welding hazards, welders should practice the following safety precautions and tips accordingly: provide adequate ventilation and local exhaust to keep fumes and gases from the breathing zone and the general area. report concerns to a supervisor so your exposure to substances of the welding fumes.

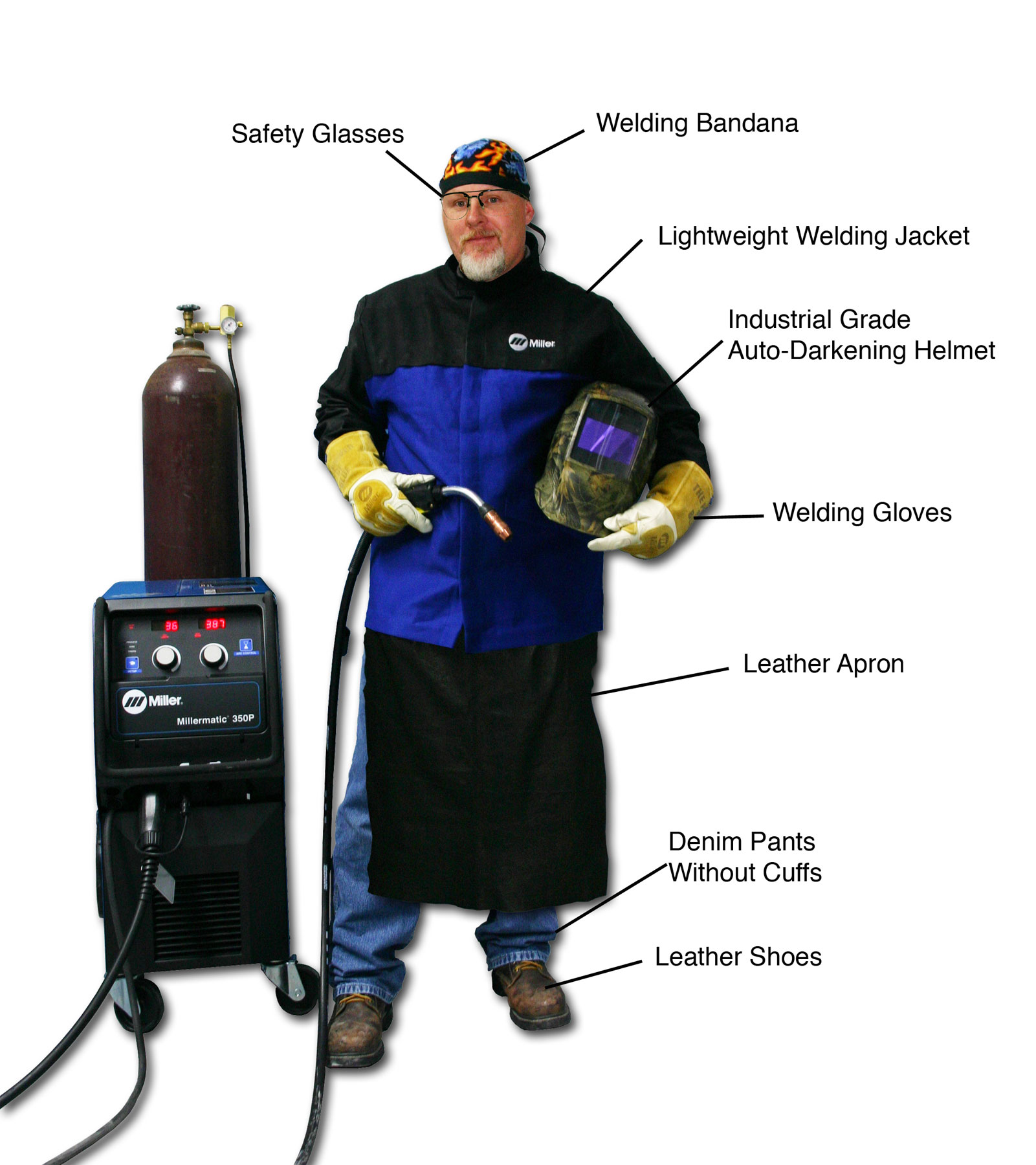

Welding Safety Tips Infographics Here are 12 tips for improving welding safety in your company, including advice that also improves productivity. 1. read the book. a welder’s operating manual contains important safety information, as well as information procedures that maximize the machine’s potential. make sure everyone who operates the machine is familiar with its contents. 1. burns (inadequate protective gear) even if you don’t come into direct contact with the welding arc, it can burn your skin. these types of burns, known as flash burns, are caused by uv radiation and strong flashes. sparks or the arc might create far more long term devastation (to the internal tissue). 2. protect yourself from fumes and gases. exposure to fumes and gases can be controlled by providing adequate ventilation in the work area. some employers will provide a fan, an exhaust system or exhaust hoods to remove fumes and gases from the area welders are working in. When welding goes awry: common pitfalls. welding, while essential for construction and fabrication, can also lead to mishaps if safety precautions are overlooked. here are a few scenarios where things can take an unfortunate turn: arc flash burns: an arc flash occurs when intense light and heat are emitted during welding. if a welder isn’t.

Safety Precautions While Working In Welding Shop Engineers Gallery 2. protect yourself from fumes and gases. exposure to fumes and gases can be controlled by providing adequate ventilation in the work area. some employers will provide a fan, an exhaust system or exhaust hoods to remove fumes and gases from the area welders are working in. When welding goes awry: common pitfalls. welding, while essential for construction and fabrication, can also lead to mishaps if safety precautions are overlooked. here are a few scenarios where things can take an unfortunate turn: arc flash burns: an arc flash occurs when intense light and heat are emitted during welding. if a welder isn’t. Additionally, affix weld leathers properly around the neck of your welding apparel to protect against splashing and high heat exposure. plasma cutting: before connecting a plasma cutter ensure all power cords are correctly installed and that a safe distance is observed while cutting (minimum 12 inches). How to stay safe while welding? as you’ve read, welding is an activity with many sources of trouble. while accidents will happen, the good news is that education, common sense, and personal discipline go a long way towards reducing the risk and severity of injuries. here’s what you can do to be safer and reduce your chances of injury.

Comments are closed.