How To Make A Drywall Access Panel Out Of Plywood Part 2 Handyma

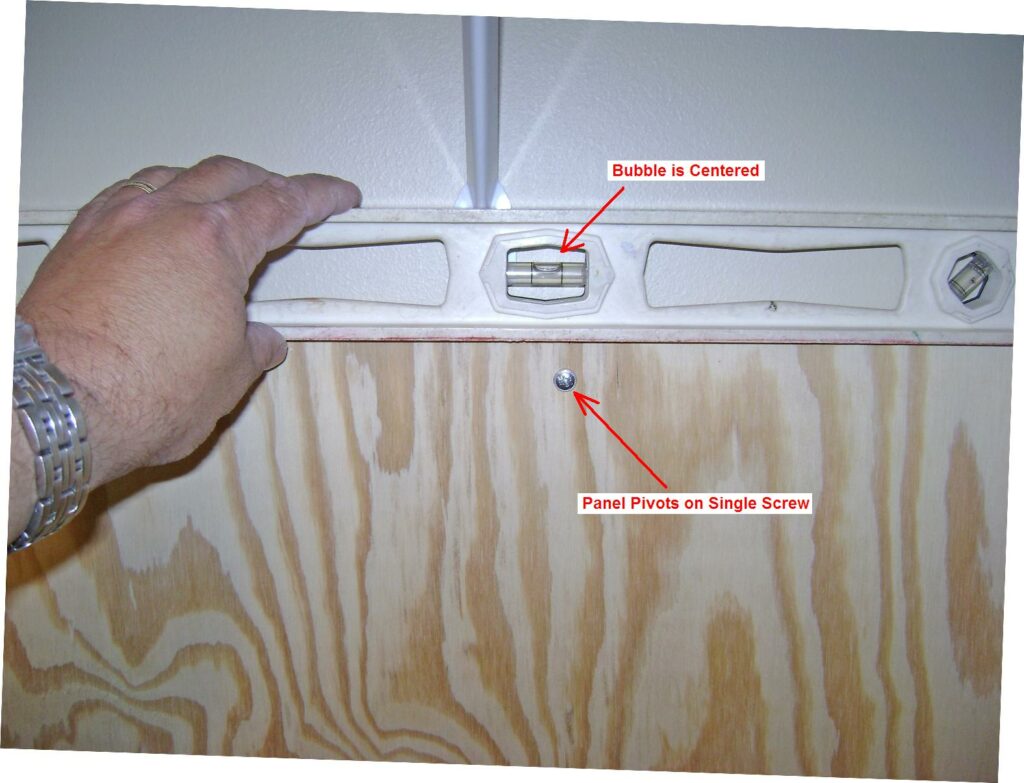

How To Make A Drywall Access Panel Out Of Plywood Part Rough drywall opening: 33 inches high x 20 inches wide. plywood panel: 35 inches high x 22 inches wide. this allows for a 1 inch weather seal around the perimeter of the plywood panel to cover the opening in the drywall. using a carpenters square, tape measure and circular saw, i measured and cut a 3 8 inch thick section of plywood to 35 x 22. Measure for the drywall access panel. to locate where the hole will be cut for the access panel, i snaked a tape measure into the wall cavity to locate the distance between two wall studs near the center of the closet. i measured the same distance inside the closet from the side wall. measuring for the access panel.

How To Make A Drywall Access Panel Out Of Plywood Handymanhowto If you guys have any questions about any of the products that i used or any of the procedures used to make this access panel let me know in the comments belo. The insulation is stapled by the flanges as shown with a 3 8 inch staples and staple gun. install each batt of insulation against the last column leaving no gaps. the kraft face (paper side) of the insulation goes against the wall. exterior wall: install r 13 fiberglass insulation. the backside of the plywood access panel is insulated as shown. Mark and cut out a rectangle or square shape that corresponds to the size of the access panel you are installing. 2. frame out the hole with 2×2 boards and secure with screws. 3. measure and cut out an appropriate piece of plywood or hardboard for your access panel. 4. attach this board to the frame with screws. 1. before drywall access panels became popular, people used to cut holes in the drywall and cover them with posters or artwork to hide them. 2. the first patent for a drywall access panel was filed in 1918 by a man named otto kreibaum. 3. in the world of professional drywall installation, access panels are sometimes referred to as “manholes.

How To Make A Drywall Access Panel Out Of Plywood Part Mark and cut out a rectangle or square shape that corresponds to the size of the access panel you are installing. 2. frame out the hole with 2×2 boards and secure with screws. 3. measure and cut out an appropriate piece of plywood or hardboard for your access panel. 4. attach this board to the frame with screws. 1. before drywall access panels became popular, people used to cut holes in the drywall and cover them with posters or artwork to hide them. 2. the first patent for a drywall access panel was filed in 1918 by a man named otto kreibaum. 3. in the world of professional drywall installation, access panels are sometimes referred to as “manholes. Using a jab saw, cut out the hole. squirt a small bead of construction adhesive along the rear perimeter of the flange, and press the housing into place. the door simply snaps into position. if you paint the plastic the same color as the wall, caulk the edges of the housing to help blend it into the wall. Here’s how it works. first, determine the size and location of the access panel, and lay out the top and bottom edges of the panel lightly on the drywall. most panels don’t need to be more than the width of a typical framing bay (14 1 2 in.), and if you’re lucky enough to have the mixing valve fall conveniently between two studs, the.

How To Make A Drywall Access Panel Out Of Plywood Handymanhowto Using a jab saw, cut out the hole. squirt a small bead of construction adhesive along the rear perimeter of the flange, and press the housing into place. the door simply snaps into position. if you paint the plastic the same color as the wall, caulk the edges of the housing to help blend it into the wall. Here’s how it works. first, determine the size and location of the access panel, and lay out the top and bottom edges of the panel lightly on the drywall. most panels don’t need to be more than the width of a typical framing bay (14 1 2 in.), and if you’re lucky enough to have the mixing valve fall conveniently between two studs, the.

Comments are closed.