How To Prevent Hydraulic Component Failures Industrial Equipment News

How To Prevent Hydraulic Component Failures Industrial Equipment News Hydraulic pumps, one of the main culprits of hydraulic failure, should also be closely monitored to prevent environmental damage and unnecessary expenditures. failing hydraulic pumps cause chain reactions, damaging other components and system parts, so it’s critical to filter hydraulic oil regularly. keeping components cool will also help. Fluid leaks are a common issue in hydraulic systems and can occur due to worn seals, loose fittings, or damaged hoses. leaks not only reduce system efficiency but can also pose safety hazards. regular inspections are essential to identify and address leaks promptly. using high quality hoses, fittings, and seals can minimize the risk of leaks.

9 Effective Ways To Prevent Hydraulic Hose Failure Fluid with the appropriate additives can help to extend the hydraulic system's life. hoses heat aging: lessen the effects of heat aging on components by ensuring that hoses running through equipment are rated for the system's operating temperature. avoid running hoses through these high temperature areas unnecessarily to ensure component longevity. We can trace most hydraulic issues back to a few common causes, listed below. 1. air and water contamination. air and water contamination are the leading causes of hydraulic failure, accounting for 80 to 90% of hydraulic failures. faulty pumps, system breaches or temperature issues often cause both types of contamination. Abrasion. one of the most common causes of hydraulic hose failure is abrasion. both external and internal abrasion can severely impact the integrity of a hydraulic hose. external abrasion occurs when the outer cover of the hose rubs against other parts of the machinery or against rough surfaces, causing it to wear down over time. Hydraulic equipment needs maintenance just like other industrial machinery. maintenance helps prevent the breakdown of hydraulic equipment. if a hydraulic machine fails unexpectedly, it means lost production and productivity, and increased costs. maintenance checks that take just a few minutes can help prevent this. safety is also a factor.

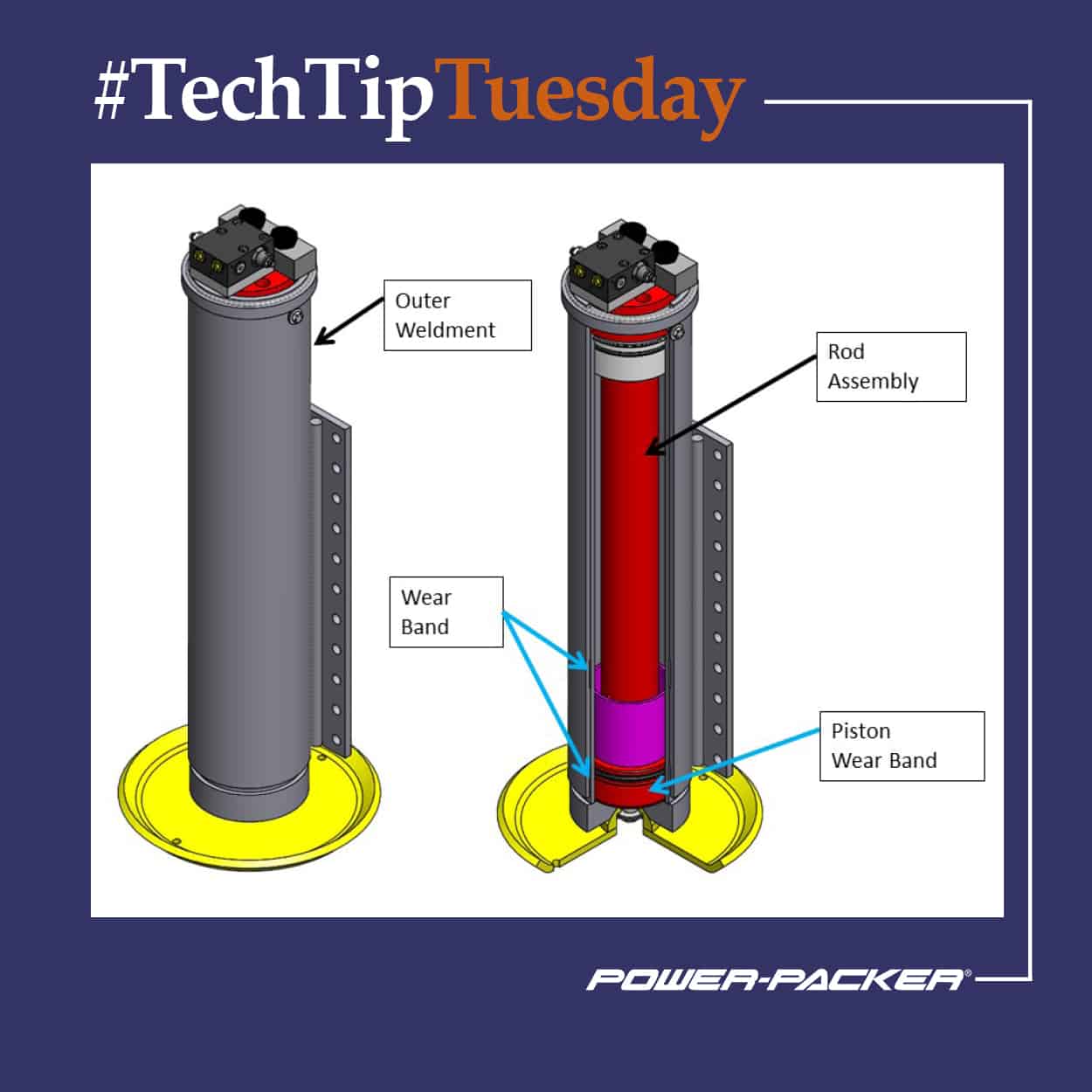

Tech Tip Tuesday Prevent Hydraulic System Contamination Abrasion. one of the most common causes of hydraulic hose failure is abrasion. both external and internal abrasion can severely impact the integrity of a hydraulic hose. external abrasion occurs when the outer cover of the hose rubs against other parts of the machinery or against rough surfaces, causing it to wear down over time. Hydraulic equipment needs maintenance just like other industrial machinery. maintenance helps prevent the breakdown of hydraulic equipment. if a hydraulic machine fails unexpectedly, it means lost production and productivity, and increased costs. maintenance checks that take just a few minutes can help prevent this. safety is also a factor. Hydraulic fluid leaks are dangerous because the organization and its workers are suddenly at risk. here are three dangers posed by hydraulic fluid leaks. damaging machines. when a machine has a. Improper assembly. the improper assembly of your hydraulic high pressure hose is a common cause of hydraulic hose failure. if the hydraulic hose fittings are not crimped and fastened adequately, high operating pressure can rapidly disclose this as a limitation. such instances can result in leaking hydraulic hose fittings as well as blown hoses.

Preventing Hydraulic Hose Failures Common Mistakes And Best Practices Hydraulic fluid leaks are dangerous because the organization and its workers are suddenly at risk. here are three dangers posed by hydraulic fluid leaks. damaging machines. when a machine has a. Improper assembly. the improper assembly of your hydraulic high pressure hose is a common cause of hydraulic hose failure. if the hydraulic hose fittings are not crimped and fastened adequately, high operating pressure can rapidly disclose this as a limitation. such instances can result in leaking hydraulic hose fittings as well as blown hoses.

Comments are closed.