How Wind Turbine Blades Are Inspected By Drones Bloomberg

Reliable Wind Turbine Drone Inspections Equinox Drones July 28, 2021 at 7:00 am edt. this article is for subscribers only. last summer, at a wind farm close to washington state’s southern border, an autonomous drone levitated 80 meters to the top of. Using drones for wind turbine blade inspection. blade inspections can be undertaken in three ways: 12 o’clock blade position: in this technique, each blade is manually positioned facing upwards. the drone flies manually or automatically along its four sides covering fully the blade surface and keeping the camera in 0 degree pitch facing.

How Wind Turbine Blades Are Inspected By Drones Bloomberg The wind energy industry is quickly integrating wind turbine drone inspections to increase inspection speed, improve accuracy, and reduce the dangers to technicians. a wind turbine is inspected in a two part process, regardless of the inspection method. each blade features dual chambers constructed of a composite laminate material. Faster inspections: drones can inspect a turbine in 45 minutes rather than 3 6 hours manually. cost savings: drones slash labor, equipment, and downtime costs. inspection expenses can drop 20 25%. better data: high res images detect tiny defects. thermal drones identify hot spots indicating problems. Here are the benefits the Ørsted team found in testing the elios 2 for an internal wind turbine blade inspection: finding #1—access. the elios 2 allowed inspectors to collect visual data on 40% more of the turbine’s blade than a human could have gathered. the elios 2 easily went beyond 32 meters (105 feet) into the blade. (bloomberg) weeks after a busted wind turbine washed onto nantucket shores, residents of this wealthy massachusetts enclave are still angry. some even liken the accident to an oil spill. most.

Wind Industry Challenged With How To Dispose Of Turbine Blades Here are the benefits the Ørsted team found in testing the elios 2 for an internal wind turbine blade inspection: finding #1—access. the elios 2 allowed inspectors to collect visual data on 40% more of the turbine’s blade than a human could have gathered. the elios 2 easily went beyond 32 meters (105 feet) into the blade. (bloomberg) weeks after a busted wind turbine washed onto nantucket shores, residents of this wealthy massachusetts enclave are still angry. some even liken the accident to an oil spill. most. Enertrag has developed an innovative solution to meet these challenges: 2in1 lps inspection. this method combines rotor blade inspection and lightning protection testing in a single process, without the need for rope access techniques. in the last 12 months, over 350 wind turbines have been successfully inspected using this technology. The skyspecs team carried out 25 turbine inspections in one day using their fully automated drone technology. previously, it took one day for our technicians to inspect one turbine alone using ropes access! by the end of the year, the skyspecs team will have inspected 350 turbines across our operating sites.”. edf uk.

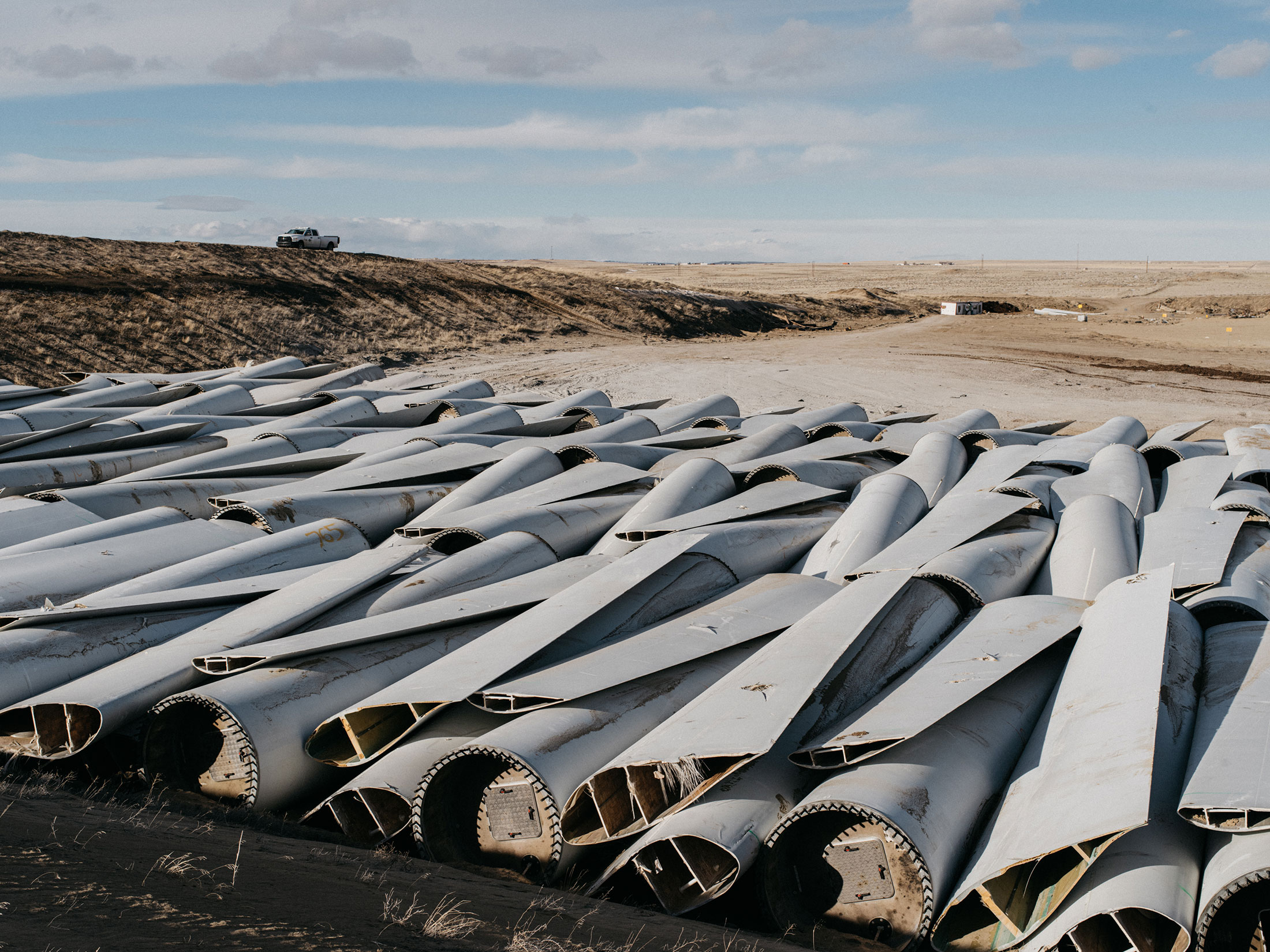

юааbloombergюаб юааwindюаб юааturbineюаб юааbladesюаб Canтащt Be Recycled So Theyтащre Piling Up Enertrag has developed an innovative solution to meet these challenges: 2in1 lps inspection. this method combines rotor blade inspection and lightning protection testing in a single process, without the need for rope access techniques. in the last 12 months, over 350 wind turbines have been successfully inspected using this technology. The skyspecs team carried out 25 turbine inspections in one day using their fully automated drone technology. previously, it took one day for our technicians to inspect one turbine alone using ropes access! by the end of the year, the skyspecs team will have inspected 350 turbines across our operating sites.”. edf uk.

Comments are closed.