Hvac Applications Predictive Engineering

Hvac Applications Predictive Engineering At predictive engineering, we developed our expertise in computational fluid dynamics (cfd) consulting with years of cfd project work in medical, aerospace, marine, hvac, civil (e.g., gas turbine power plants) and automotive. our work has been extensively benchmarked by experiments and in service testing, giving us the necessary validation. Predictive control offers significant advantages in nonlinear control, high thermal inertia, and dynamic control. this article uses a systematic reviews and meta analyses methodology to review 245 studies on predictive control in hvac systems over the past 12 years, focusing on model predictive control (mpc) and model free predictive control (mfpc).

Hvac Applications Predictive Engineering A cornerstone application, predictive maintenance, employs ai to foresee equipment malfunctions, enabling timely interventions and minimizing operational downtimes. furthermore, ai driven energy optimization yields substantial financial savings and a commendable reduction in environmental impact. harmonizing hvac automation and ai. Predictive control offers significant advantages in nonlinear control, high thermal inertia, and dynamic control. this article uses a systematic reviews and meta analyses methodology to review 245 studies on predictive control in hvac systems over the past 12 years, focusing on model predictive control (mpc) and model free predictive control (mfpc). Buildings use up to 40% of the global primary energy and 30% of global greenhouse gas emissions, which may significantly impact climate change. heating, ventilation, and air conditioning (hvac) systems are among the most significant contributors to global primary energy consumption and carbon gas emissions. furthermore, hvac energy demand is expected to rise in the future. therefore. Abstract. model predictive control is widely used as a control technology for the computation of optimal control inputs of building heating, ventilating, and air conditioning (hvac) systems. however, both the benefits and widespread adoption of model predictive control (mpc) are hindered by the effort of model creation, calibration, and accuracy of the predictions. in this paper, we apply the.

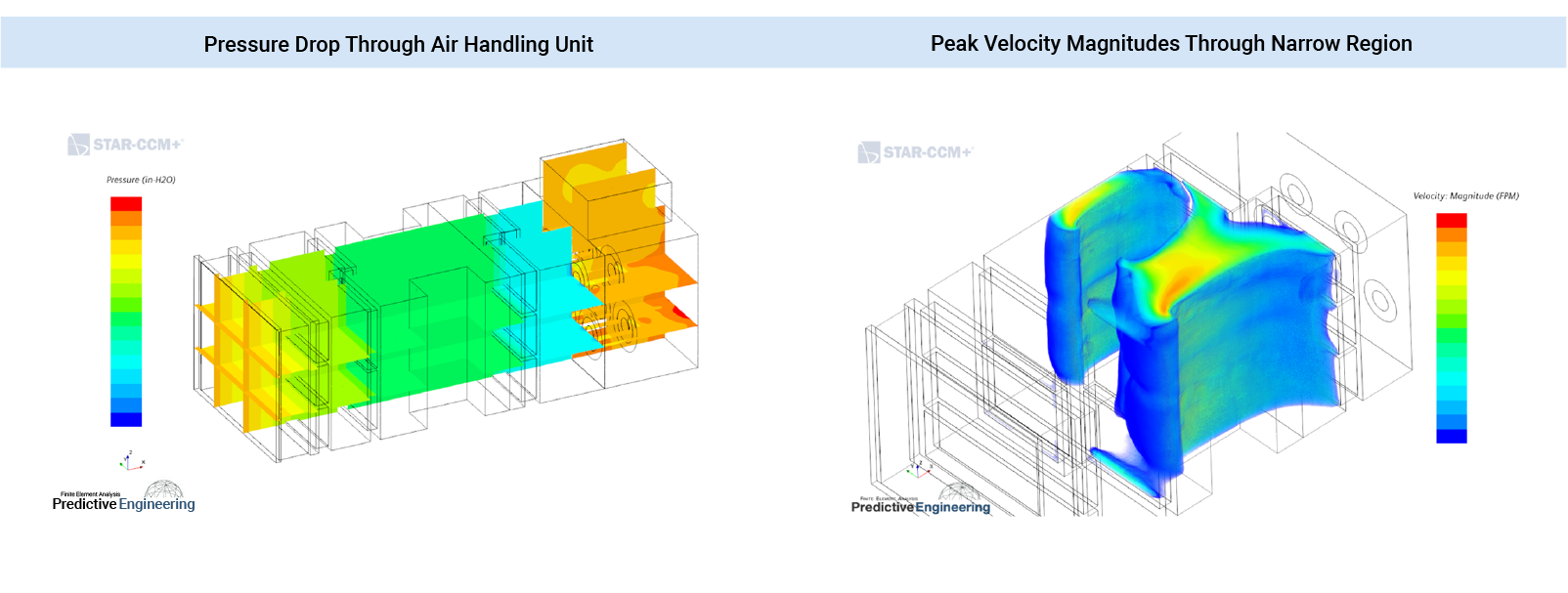

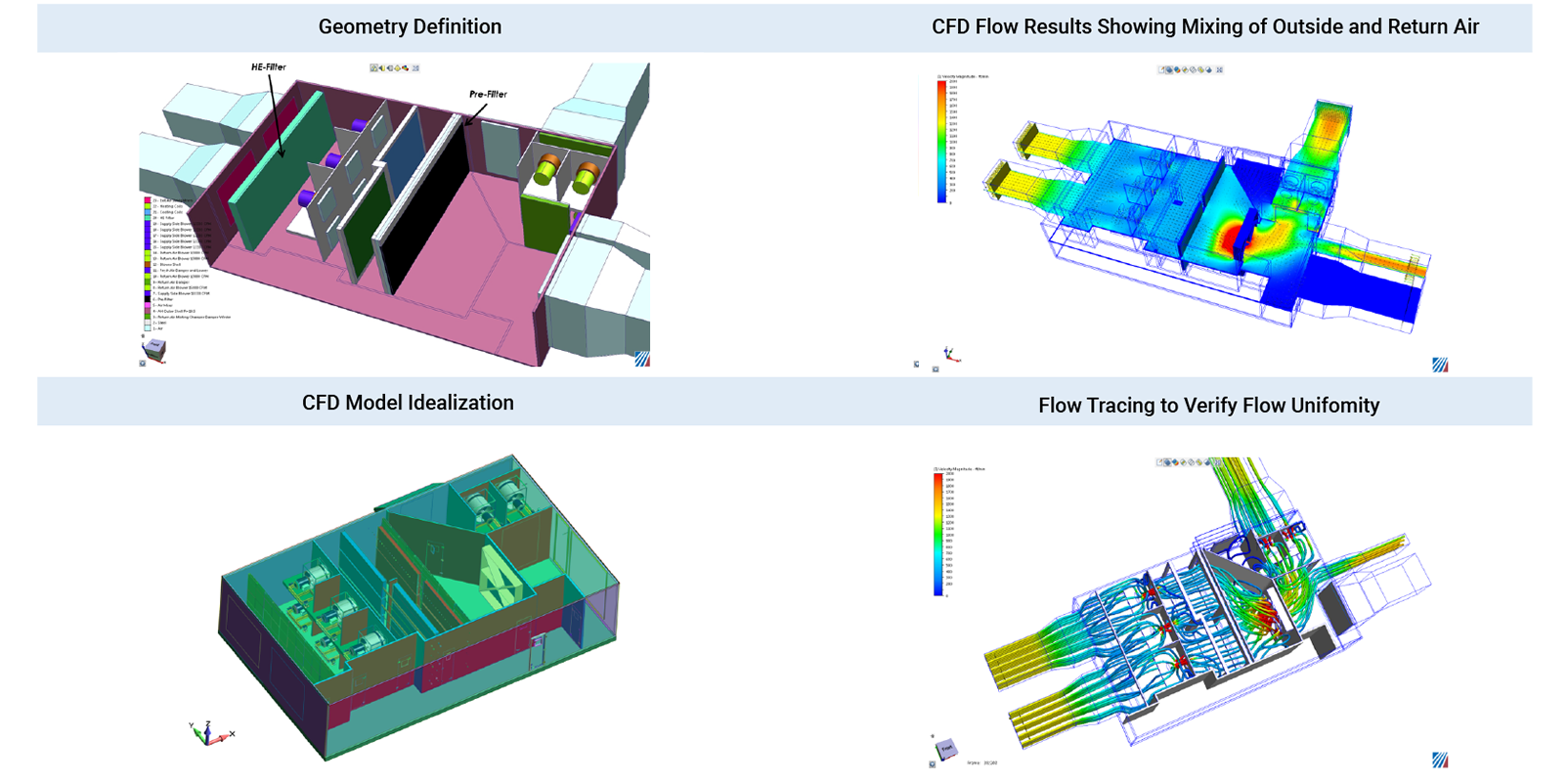

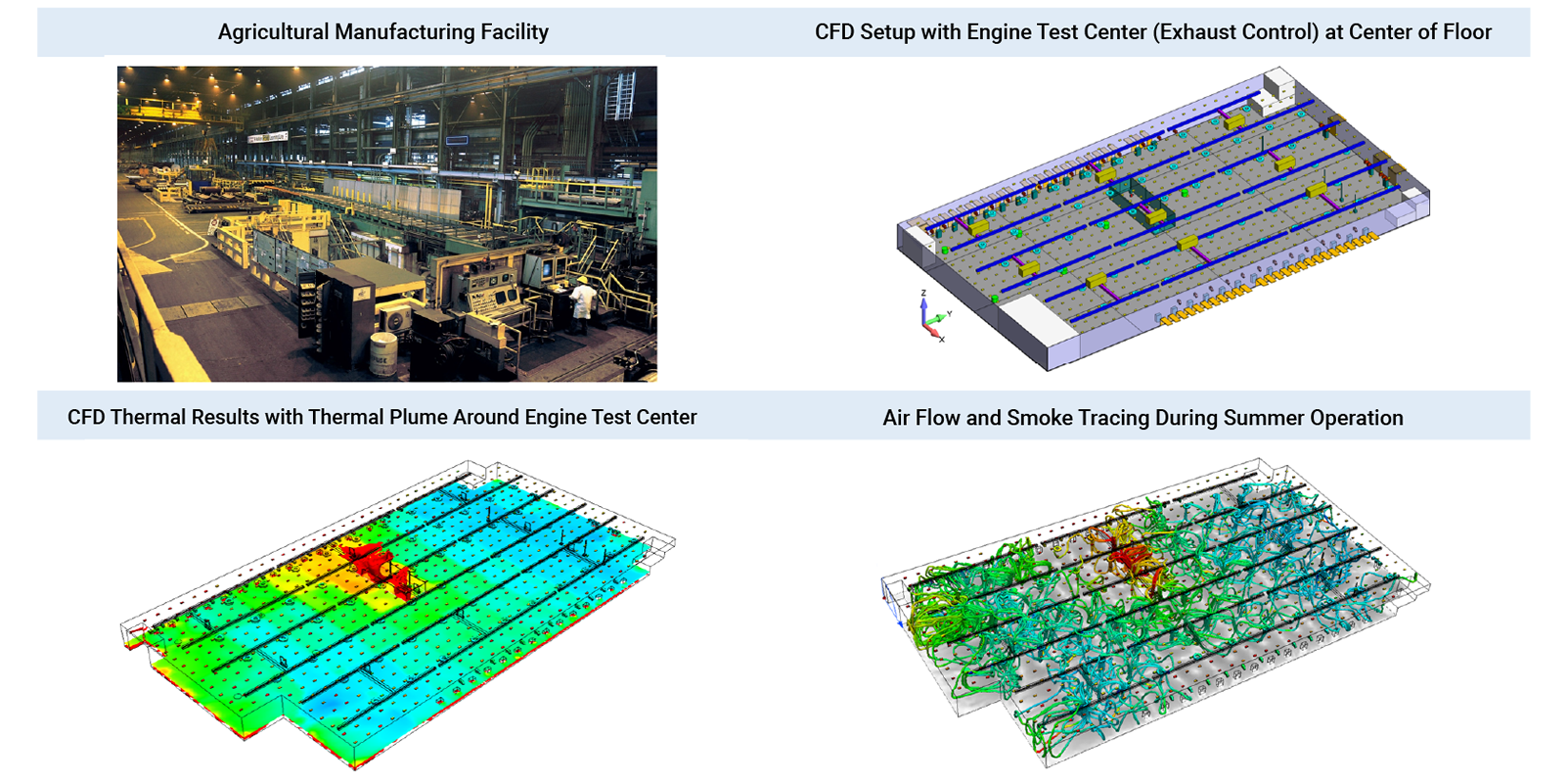

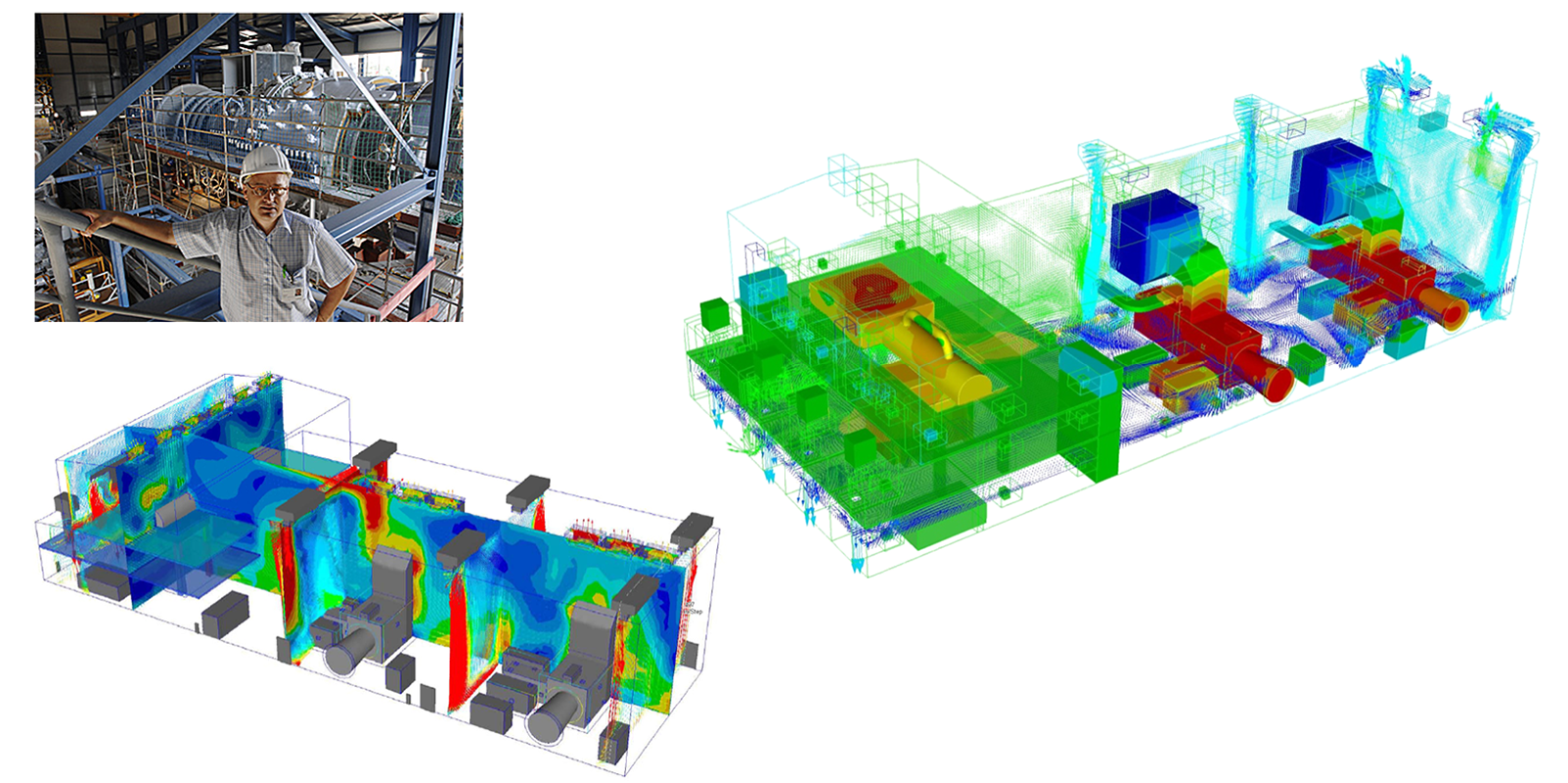

Hvac Applications Predictive Engineering Buildings use up to 40% of the global primary energy and 30% of global greenhouse gas emissions, which may significantly impact climate change. heating, ventilation, and air conditioning (hvac) systems are among the most significant contributors to global primary energy consumption and carbon gas emissions. furthermore, hvac energy demand is expected to rise in the future. therefore. Abstract. model predictive control is widely used as a control technology for the computation of optimal control inputs of building heating, ventilating, and air conditioning (hvac) systems. however, both the benefits and widespread adoption of model predictive control (mpc) are hindered by the effort of model creation, calibration, and accuracy of the predictions. in this paper, we apply the. The main objective of predictive maintenance of heating, ventilation, and air conditioning (hvac) systems is to predict when the hvac equipment failure may occur. the benefits are numerous: planning of maintenance before the failure occurs, reduction of maintenance costs, and increased reliability. for this, the predictive maintenance of the. At predictive engineering, we developed our expertise in computational fluid dynamics (cfd) consulting with years of cfd project work in medical, aerospace, marine, hvac, civil (e.g., gas turbine power plants) and automotive. our work has been extensively.

Hvac Applications Predictive Engineering The main objective of predictive maintenance of heating, ventilation, and air conditioning (hvac) systems is to predict when the hvac equipment failure may occur. the benefits are numerous: planning of maintenance before the failure occurs, reduction of maintenance costs, and increased reliability. for this, the predictive maintenance of the. At predictive engineering, we developed our expertise in computational fluid dynamics (cfd) consulting with years of cfd project work in medical, aerospace, marine, hvac, civil (e.g., gas turbine power plants) and automotive. our work has been extensively.

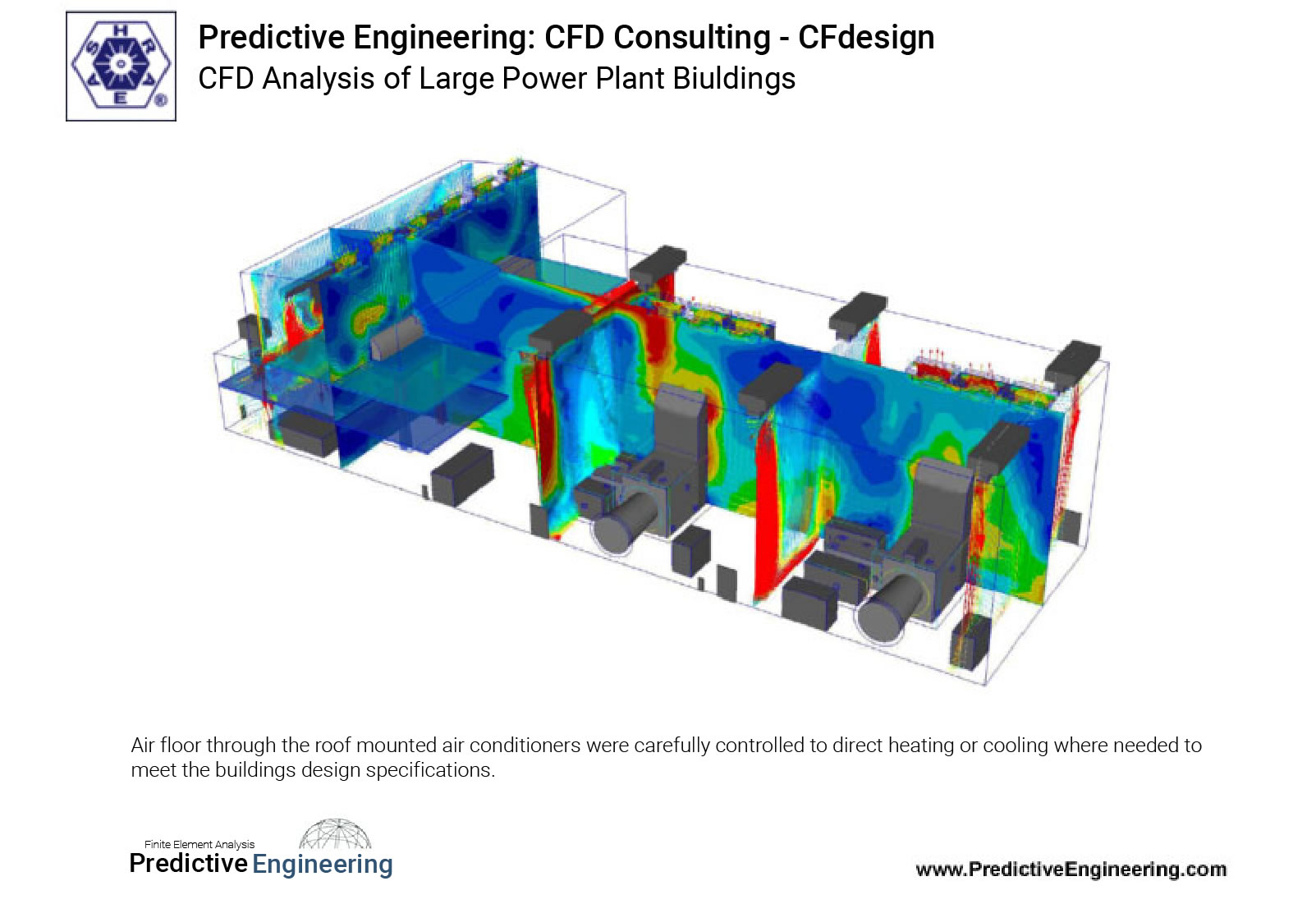

Hvac Cfd Modeling Of Large Power Plant Buildings Predictive Engineering

Comments are closed.