Hydraulic Cylinder Types Explained Worlifts

5 Signs Your Hydraulic Cylinder Has A Problem Hollow plunger cylinders, sometimes referred to as hollow plunger cylinders, are often used for push and pull configurations. this is thanks to the threaded collar inside the plunger, allowing for attachments like fixing rods to be connected to the hydraulic system. for more control or force, a hollow plunger cylinder can be double acting as well. Double acting hydraulic cylinders use hydraulics to extend and retract the plunger. it requires two connections; one where the hydraulic fluid is used to extend the plunger, and the other is used.

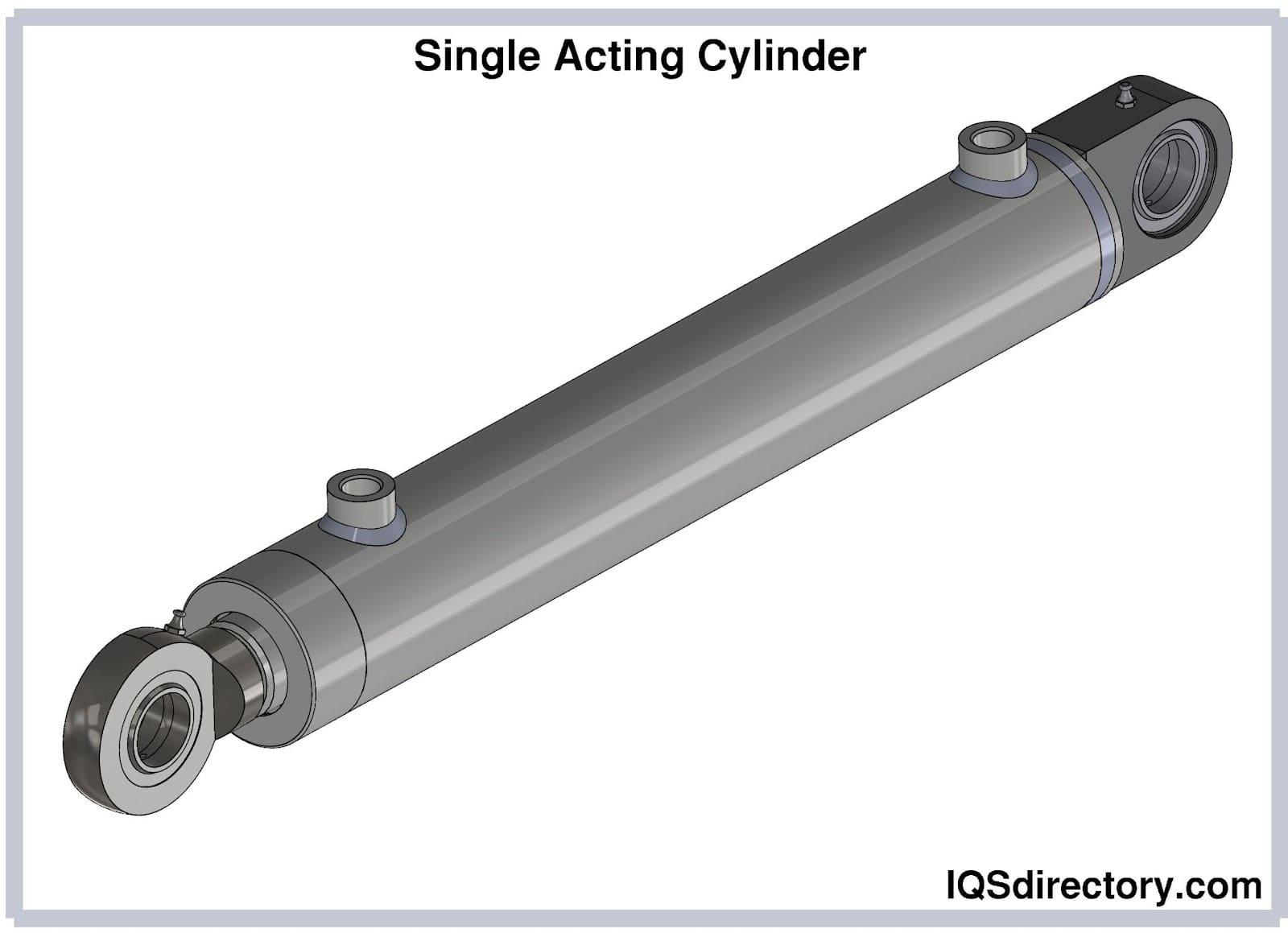

Hydraulic Piston Both single and double acting cylinders have hollow plunger and high tonnage variants, but low profile designs are mainly designed as single acting due to the space constraints. single acting hydraulic cylinders are typically used for applications such as: simple lifting and positioning tasks. clamping devices. There are many manufacturers of hydraulic press machines. and some manufacturers are recommended over others based on quality. some of the best include enerpac, savage and beckwood. you can order hydraulic presses from reputable resellers or direct from manufacturers. there are also many types of liquid powered press, and the one you need. Understandably when it comes to making the correct selection for your application needs it can be a little confusing so this guide takes a closer look at a range of hydraulic cylinder types to. Hydraulic cylinders transform the pressure and oil flow in a hydraulic system into work or mechanical force. they are used where linear motion is required to move something. also known as ‘hydraulic jacks’, ‘hydraulic rams’ or ‘actuators’, they convert fluid power into mechanical energy. a hydraulic cylinder differs from a hydraulic.

Hydraulic Cylinder Types Explained Worlifts Understandably when it comes to making the correct selection for your application needs it can be a little confusing so this guide takes a closer look at a range of hydraulic cylinder types to. Hydraulic cylinders transform the pressure and oil flow in a hydraulic system into work or mechanical force. they are used where linear motion is required to move something. also known as ‘hydraulic jacks’, ‘hydraulic rams’ or ‘actuators’, they convert fluid power into mechanical energy. a hydraulic cylinder differs from a hydraulic. A hydraulic cylinder's operation is a marvel of engineering simplicity and efficiency. at its core, the cylinder uses pressurized hydraulic fluid, typically oil, to exert force. the cylinder consists of a barrel housing a piston connected to a piston rod. this piston divides the cylinder into two chambers: the cap end and the rod end. Tie rod cylinders. tie rod hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel. they are held together by four or more threaded tie bolts that run the length of the entire cylinder tube. these bolts hold the baseplate and head together. they usually have static seals to prevent leakage.

Comments are closed.