Hydraulic Cylinders Design Working Types Hydraulic Suspension

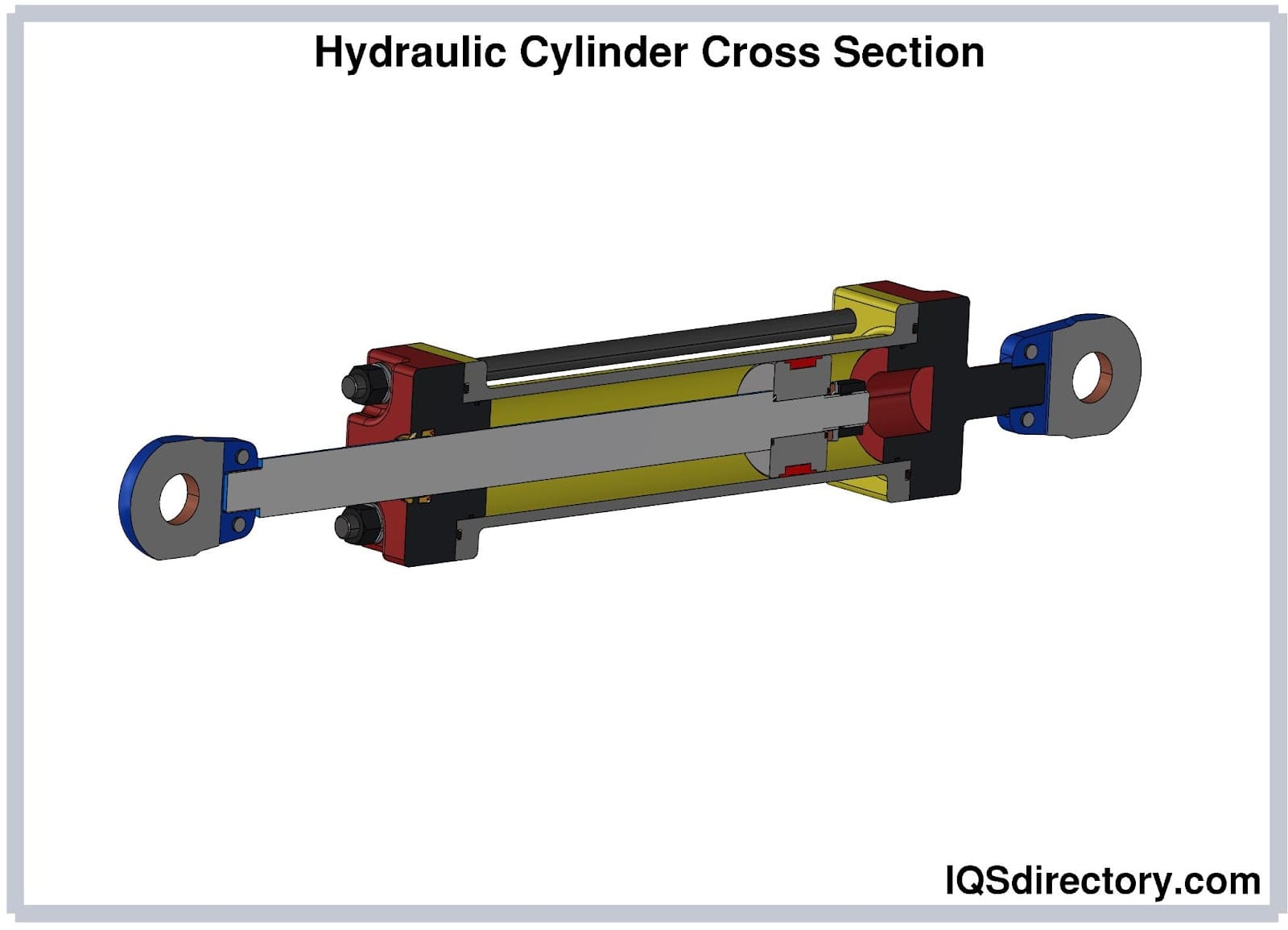

5 Signs Your Hydraulic Cylinder Has A Problem Hydraulic cylinders are used for creating mechanical force in a linear motion. a hydraulic cylinder is a tube capped at either end with a rod sticking out of one side. attached to the rod, interior to the cylinder, is a piston. the piston separates the internal rod side from the internal cap side of the cylinder. 3. Hydraulic cylinders transform the pressure and oil flow in a hydraulic system into work or mechanical force. they are used where linear motion is required to move something. also known as ‘hydraulic jacks’, ‘hydraulic rams’ or ‘actuators’, they convert fluid power into mechanical energy. a hydraulic cylinder differs from a hydraulic.

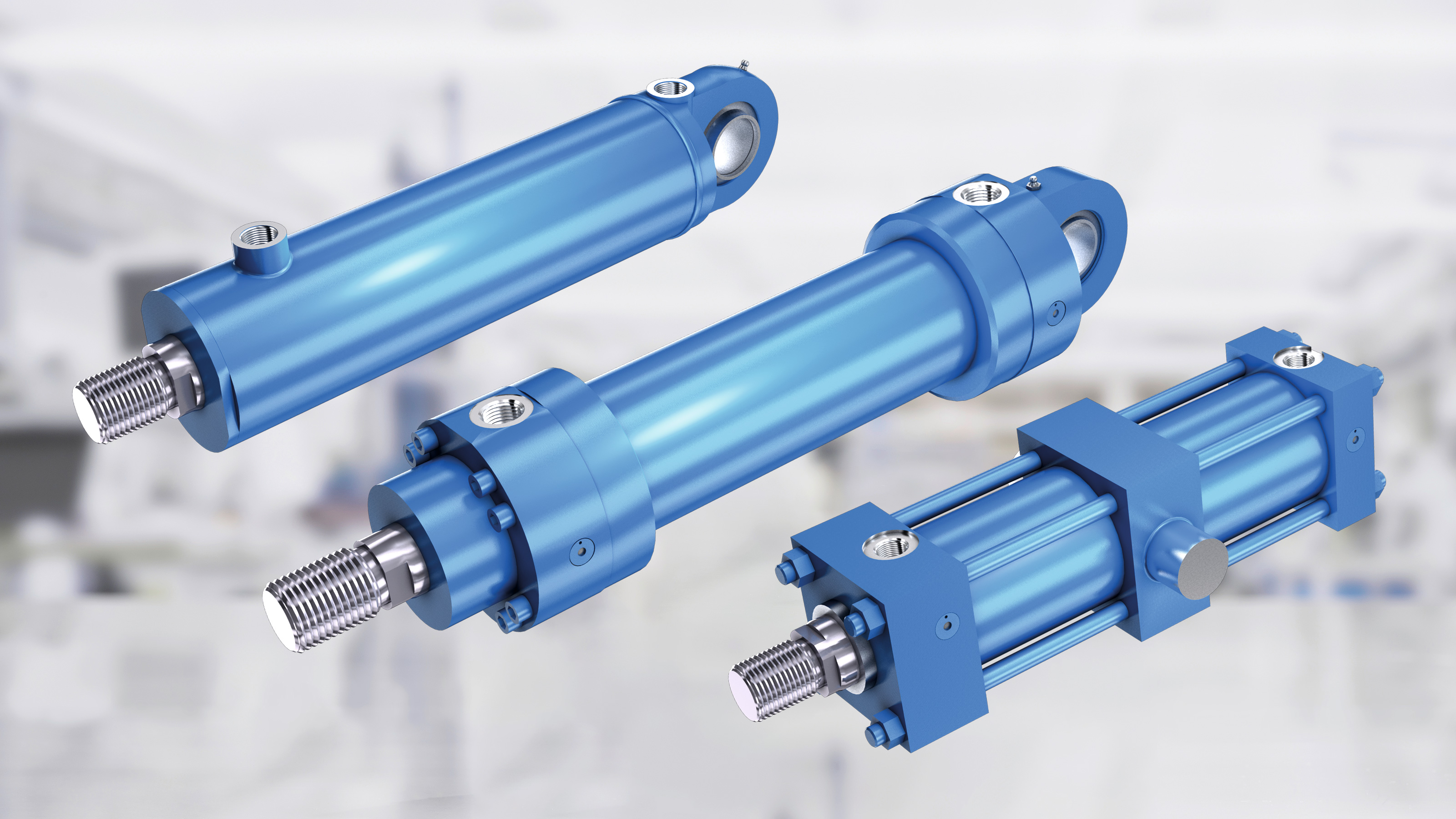

Hydraulic Cylinders All You Need To Know Rhrcemeteryandfuneralhome Rapid traverse cylinder (single acting) with this type of cylinder, as long as not the whole working force is required, only part of the effective piston area, the so called rapid traverse piston is pressurized. the total effective piston area is connected later to the hydraulic pump, by the response of pressure valves or limit switches. Visually, these welded body cylinders tend to have lower profiles than tie rod cylinders which improves the appearance of the equipment they are mounted on. because they are narrower than tie rod ones, welded hydraulic cylinders work well in situations where space is a factor. chapter 3: design of hydraulic cylinders. Hydraulic suspension systems are a critical aspect of modern vehicle design, contributing to superior ride quality and vehicle stability. delving into these systems reveals a complex interplay of components and fluids that work in harmony to deliver a smooth and adjustable ride. this guide will provide you with an in depth understanding of the. Tie rod cylinders. tie rod hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel. they are held together by four or more threaded tie bolts that run the length of the entire cylinder tube. these bolts hold the baseplate and head together. they usually have static seals to prevent leakage.

Guide To Understand Hydraulic Cylinder Parts Names Diagram Hydraulic suspension systems are a critical aspect of modern vehicle design, contributing to superior ride quality and vehicle stability. delving into these systems reveals a complex interplay of components and fluids that work in harmony to deliver a smooth and adjustable ride. this guide will provide you with an in depth understanding of the. Tie rod cylinders. tie rod hydraulic cylinders use high strength threaded steel rods to hold the two end caps to the cylinder barrel. they are held together by four or more threaded tie bolts that run the length of the entire cylinder tube. these bolts hold the baseplate and head together. they usually have static seals to prevent leakage. A tie rod hydraulic cylinder uses threaded steel rods to hold two end caps to the ends of the cylinder barrel. applications can use anywhere from 4 to 20 tie rods depending on the bore diameter and operating pressure. a strong advantage of the tie rod design is that it can be easily disassembled and examined for repair. Design factors in hydraulic cylinder specification specifying hydraulic cylinders is essentially a balancing act as each design factor influences one or more of the many other design considerations. for example, the urethane seals ideal for applications as cold as 65°f ( 54°c) will tolerate 200°f (129°c) of heat, while other.

Hydraulic Cylinders Types Design Applications And Piston Configuration A tie rod hydraulic cylinder uses threaded steel rods to hold two end caps to the ends of the cylinder barrel. applications can use anywhere from 4 to 20 tie rods depending on the bore diameter and operating pressure. a strong advantage of the tie rod design is that it can be easily disassembled and examined for repair. Design factors in hydraulic cylinder specification specifying hydraulic cylinders is essentially a balancing act as each design factor influences one or more of the many other design considerations. for example, the urethane seals ideal for applications as cold as 65°f ( 54°c) will tolerate 200°f (129°c) of heat, while other.

Hydraulic Cylinders Types Design Applications And Piston Configuration

Comments are closed.