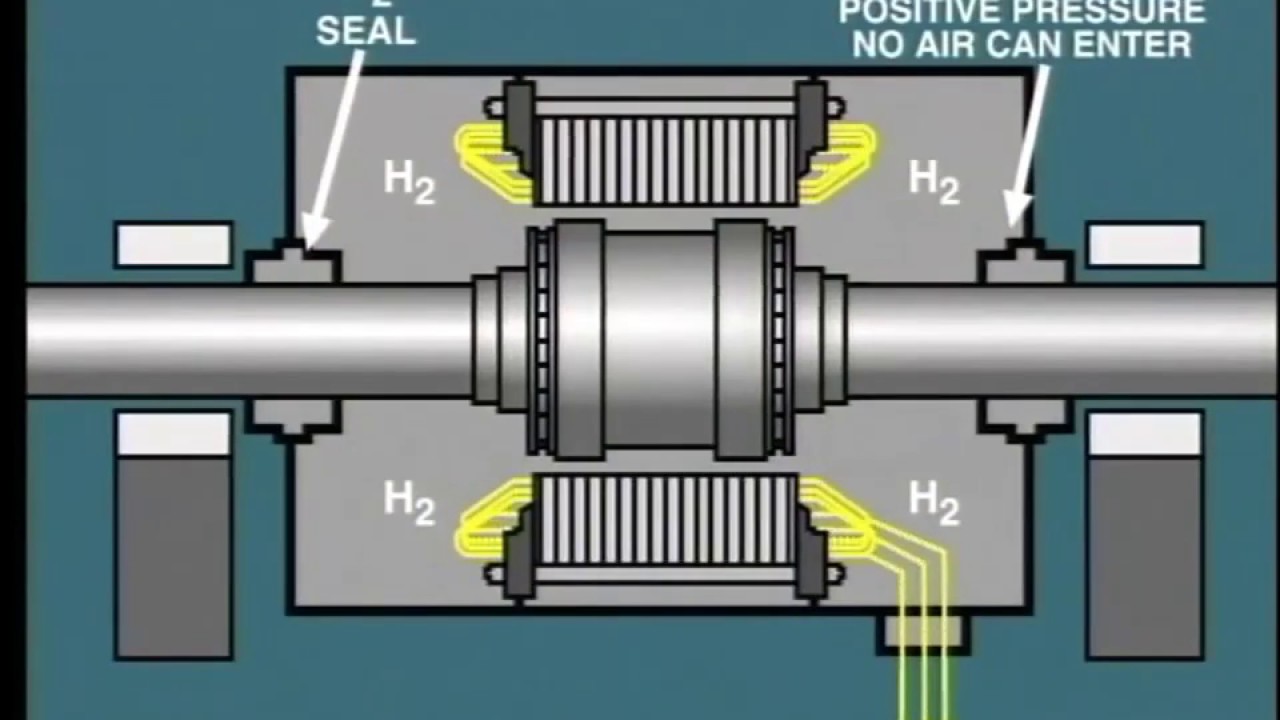

Hydrogen Cooled Generator Diagram

Hydrogen Generator Diagram 99%. =((0.99*1) (0.01*14.4))*100. because air is 14 times as dense as hydrogen, the density of the fluid in the generator casing rises quickly with air impurity level. as can be seen from the equation, every 1 percent of air contamination is worth about 14% increase in fluid density. increased fluid density means increased windage loss. A hydrogen cooled turbo generator is a turbo generator with gaseous hydrogen as a coolant. hydrogen cooled turbo generators are designed to provide a low drag atmosphere and cooling for single shaft and combined cycle applications in combination with steam turbines. [ 1] because of the high thermal conductivity and other favorable properties.

Figure 2 From Development Of World S Largest Hydrogen Cooled Turbine Hydrogen cooled generator. (gen h) ge’s hydrogen cooled generator systems are the right fit for high efficiency applications and can operate in both simple and combined cycle power plants. their high power output makes them a more cost effective than solution than many water cooled machines. up to 755 mva. apparent power. up to 99.02%. This drawing shows the unit 1 generator field (1935) which is air cooled; in 1943 hydrogen cooling became practical, which reduced the field size by about 30%. Hydrogen cooled turbo generators are characterized by a compact design, lowest losses in operation and the highest possible efficiency due to the characteris tics of hydrogen (h 2) – having better heat dissipation than air, low density and thermal conductivity. the absence of oxygen (o2) prevents from damaging the generator’s high voltage. Continuous online gas analysis is used in hydrogen cooled electric power generators for the following purposes: generator eficiency: maintaining a high concentration of hydrogen coolant increases the cooling eficiency of the generator (see figure 1 for the cost of decreased hydrogen purity). plant and process safety: air in the hydrogen coolant.

Lesson 2 Hydrogen Cooled Synchronous Generator Youtube Hydrogen cooled turbo generators are characterized by a compact design, lowest losses in operation and the highest possible efficiency due to the characteris tics of hydrogen (h 2) – having better heat dissipation than air, low density and thermal conductivity. the absence of oxygen (o2) prevents from damaging the generator’s high voltage. Continuous online gas analysis is used in hydrogen cooled electric power generators for the following purposes: generator eficiency: maintaining a high concentration of hydrogen coolant increases the cooling eficiency of the generator (see figure 1 for the cost of decreased hydrogen purity). plant and process safety: air in the hydrogen coolant. 3. cooled sgen 2000h generator series: referencesour hydrogen cooled two pole generator series exceeds an availability of 99.5% and counts with more than 100,000 operating hours which have earned siemens a flawless reputation in the filed of reliable powe. generation steam and gas turbine applications. therefore, the following references are. Many power generators over 150 mw in capacity utilize hydrogen as a cooling method to transfer heat from the power generating winding enclosure to the heat exchanges known as h2 coolers. hydrogen cooled power generators are more efficient and have less mass of materials of construction than their air cooled cousins.

Electrical Engineering World A Hydrogen Cooled Generator From Toshiba 3. cooled sgen 2000h generator series: referencesour hydrogen cooled two pole generator series exceeds an availability of 99.5% and counts with more than 100,000 operating hours which have earned siemens a flawless reputation in the filed of reliable powe. generation steam and gas turbine applications. therefore, the following references are. Many power generators over 150 mw in capacity utilize hydrogen as a cooling method to transfer heat from the power generating winding enclosure to the heat exchanges known as h2 coolers. hydrogen cooled power generators are more efficient and have less mass of materials of construction than their air cooled cousins.

Comments are closed.