In A Standard Double Acting Telescopic Cylinder Design Both The

Efficient Telescoping Hydraulic Cylinders The classic single acting telescopic applications are dump trucks and dump trailers. pressurized oil extends the telescopic cylinder to raise one end of the dump body. when pressure is released, the weight the dump body forces oil out of the cylinder, it retracts. double acting telescopic cylinders are powered hydraulically in both directions. If the cylinder must be hydraulically powered in both directions, the solution is a double acting telescopic cylinder. however, a common mistake is expecting a double acting telescopic cylinder to replicate the performance of a typical single stage double acting cylinder.

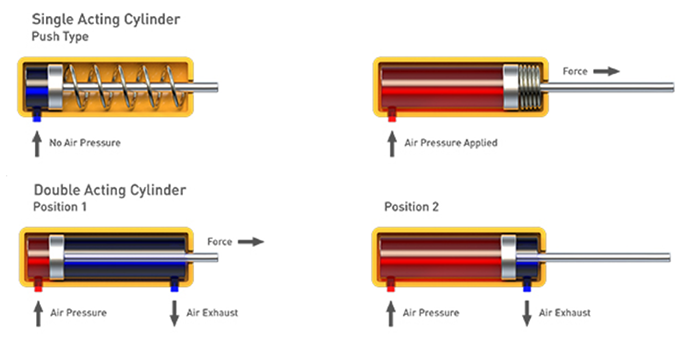

Usha Double Acting Telescopic Cylinder For Heavy Duty Vehicle Lifting In a standard double acting telescopic cylinder design, both the hydraulic extend and retract ports are located in the plunger (smallest sleeve). once this stage is fully retracted, the oil transfer hole in the next larger stage is exposed to allow oil flow for it to retract. The design of double acting telescopic cylinders enables bi directional hydraulic operation, meaning they can exert force in both extension and retraction directions. this is achieved through the implementation of hydraulic ports at both ends of the cylinder, allowing hydraulic fluid to be directed to either side of the piston as needed. Retraction of double acting telescopic cylinders is made possible by sealing each moving stage’s piston area outside diameter with the next larger stage’s inside diameter and building internal oil transfer holes into each moving stage. the oil transfer holes are located just above the pistons in the body of the stage. The standard double acting cylinder with piston rod out one end, is used in the majority of applications. it develops force in both directions of piston travel. the double end rod type is a variation of the standard cylinder but having a piston rod extending out both end caps.

Misdrijf Portret Uitgaan Telescope Cylinder Struik Doorlaatbaarheid Retraction of double acting telescopic cylinders is made possible by sealing each moving stage’s piston area outside diameter with the next larger stage’s inside diameter and building internal oil transfer holes into each moving stage. the oil transfer holes are located just above the pistons in the body of the stage. The standard double acting cylinder with piston rod out one end, is used in the majority of applications. it develops force in both directions of piston travel. the double end rod type is a variation of the standard cylinder but having a piston rod extending out both end caps. Telescopic hydraulic cylinders, sometimes called multi stage cylinders, allow for a long stroke while maintaining a short retracted length. this is achieved with 2 or more nested stages which help to achieve a longer working stroke than a single stage rod style actuator is capable of. rhk’s technical sales and engineering teams have extensive. Bleeders are not usually needed in the double acting since the cylinder fills with oil on both ends. 10. end fittings an assortment of end fittings are provided for both ends of the cylinder to fit various applications. 11. custom design special designs are also manufactured. one of our plants specializes the manufacture of telescopic’s of.

How Can You Achieve Cylinder Flow Reduction Fluid Power World Telescopic hydraulic cylinders, sometimes called multi stage cylinders, allow for a long stroke while maintaining a short retracted length. this is achieved with 2 or more nested stages which help to achieve a longer working stroke than a single stage rod style actuator is capable of. rhk’s technical sales and engineering teams have extensive. Bleeders are not usually needed in the double acting since the cylinder fills with oil on both ends. 10. end fittings an assortment of end fittings are provided for both ends of the cylinder to fit various applications. 11. custom design special designs are also manufactured. one of our plants specializes the manufacture of telescopic’s of.

Telescopic Hydraulic Cylinder Pressuretech Hydraulic Conveyors

Comments are closed.