Induction Heating Induction Heat Treating Surface Process

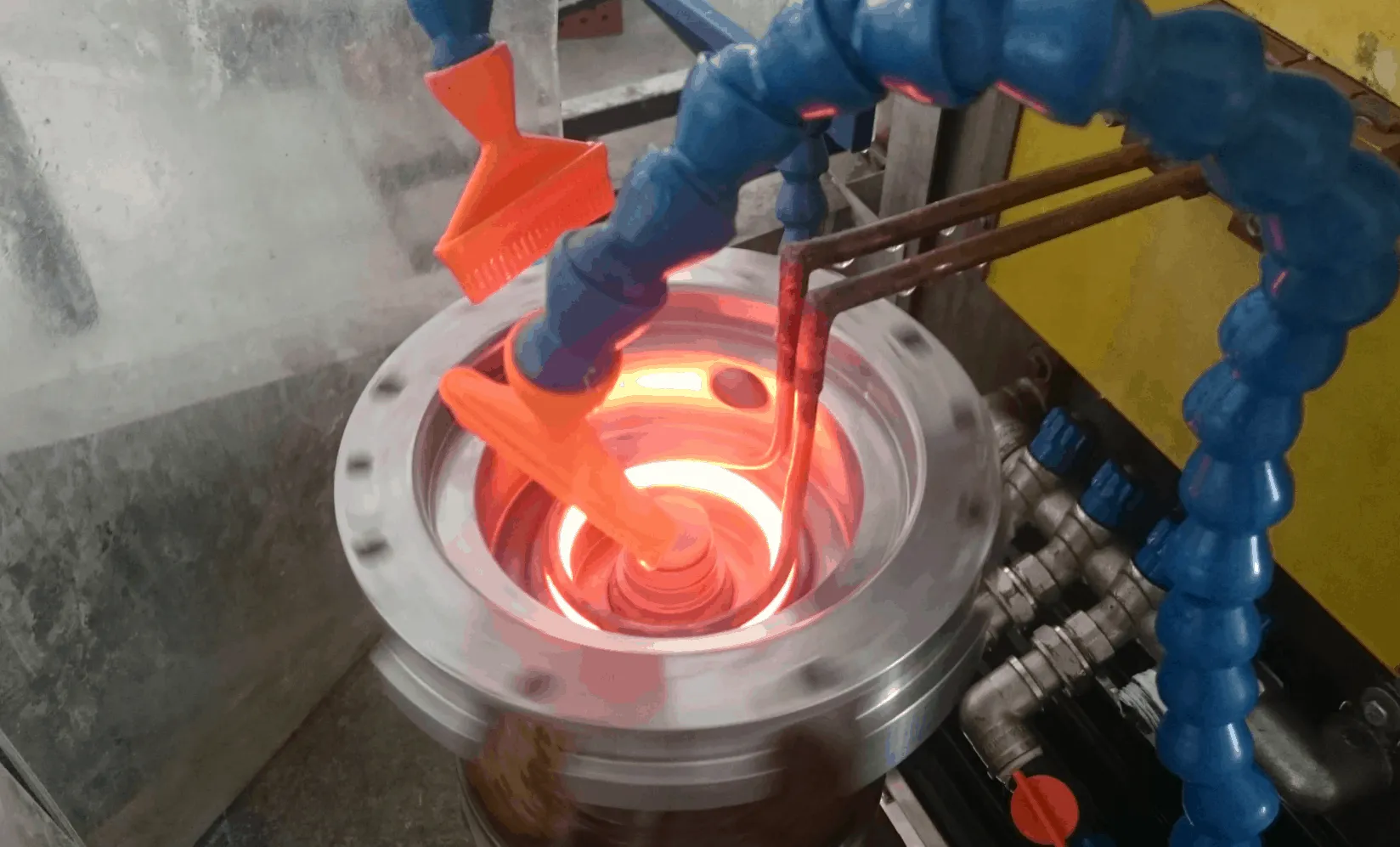

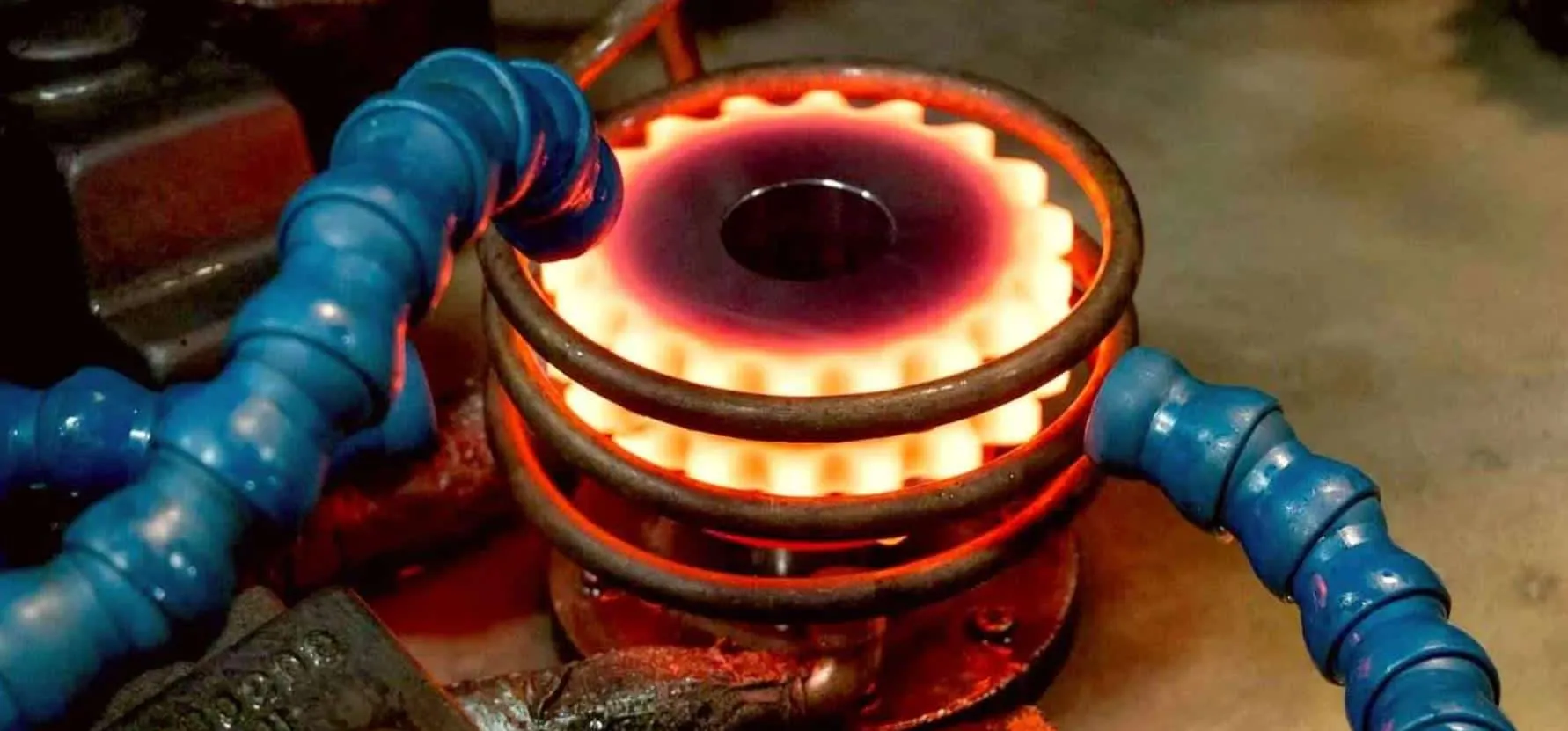

Induction Heat Treating Surface Process вђ Hlq Induction Heat Definition. surface hardening of carbon steel and iron is the most common form of induction heat treatment because the heat can be localized to the areas where the microstructural changes are desired. this process is a complex combination of electromagnetic, heat transfer, and microstructural changes that occur when a workpiece is heated. For induction hardening, frequencies are split into two groups: medium frequency (mf) and radio frequency (rf). the mf range is typically from 3 50khz, and rf is from 100 400khz. power is important because it will determine how large of a part you can harden, and how long the heat time will need to be.

Induction Heating Induction Heat Treating Surface Process Induction heating is the process of heating electrically conductive materials, namely metals or semi conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide. Induction heating fundamental laws: maxwell’s equations 3rd maxwell’s equation (from the induction heating viewpoint): the time variation of the magnetic flux generates an electromotive force e. • it applies to every time variation (either periodic or non periodic). • periodic time variation à frequency is defined. An acknowledged expert on induction hardening, kristian became managing director of efd induction sweden in 2007. in addition to writing the section on induction heating for the book ‘steel and its heat treatment—a handbook’, kristian has written and co authored numerous articles about induction hardening. Introduction induction heating is used in the industry over the past three decades. due to the rapid heating and good repro ducibility are used in applications the heat treatment. in recent years, there has been significant interest in expanding the use of induction heating process in different manufacturing process.

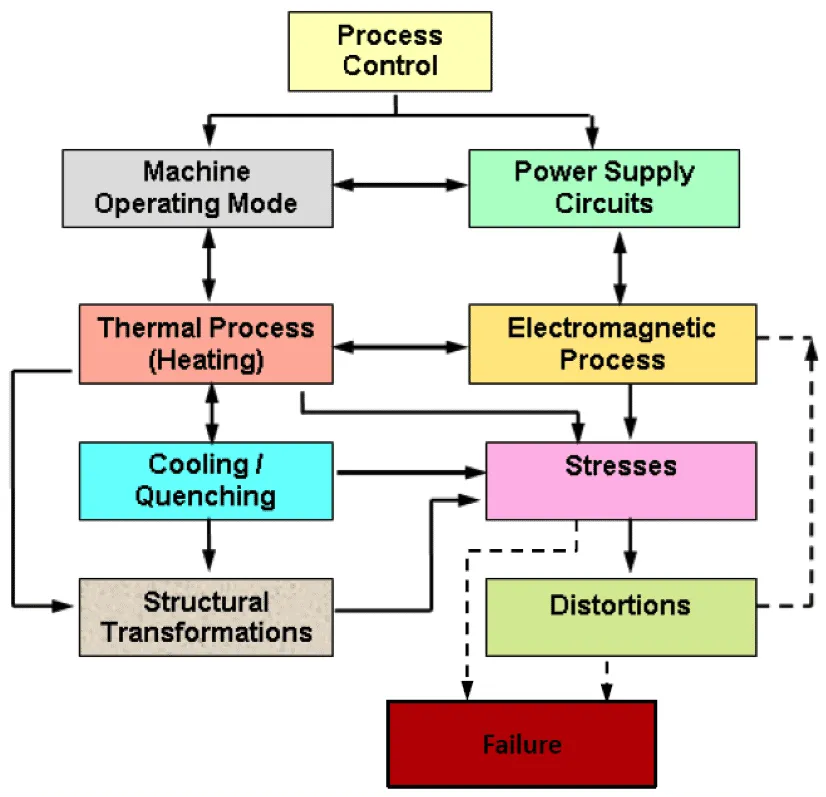

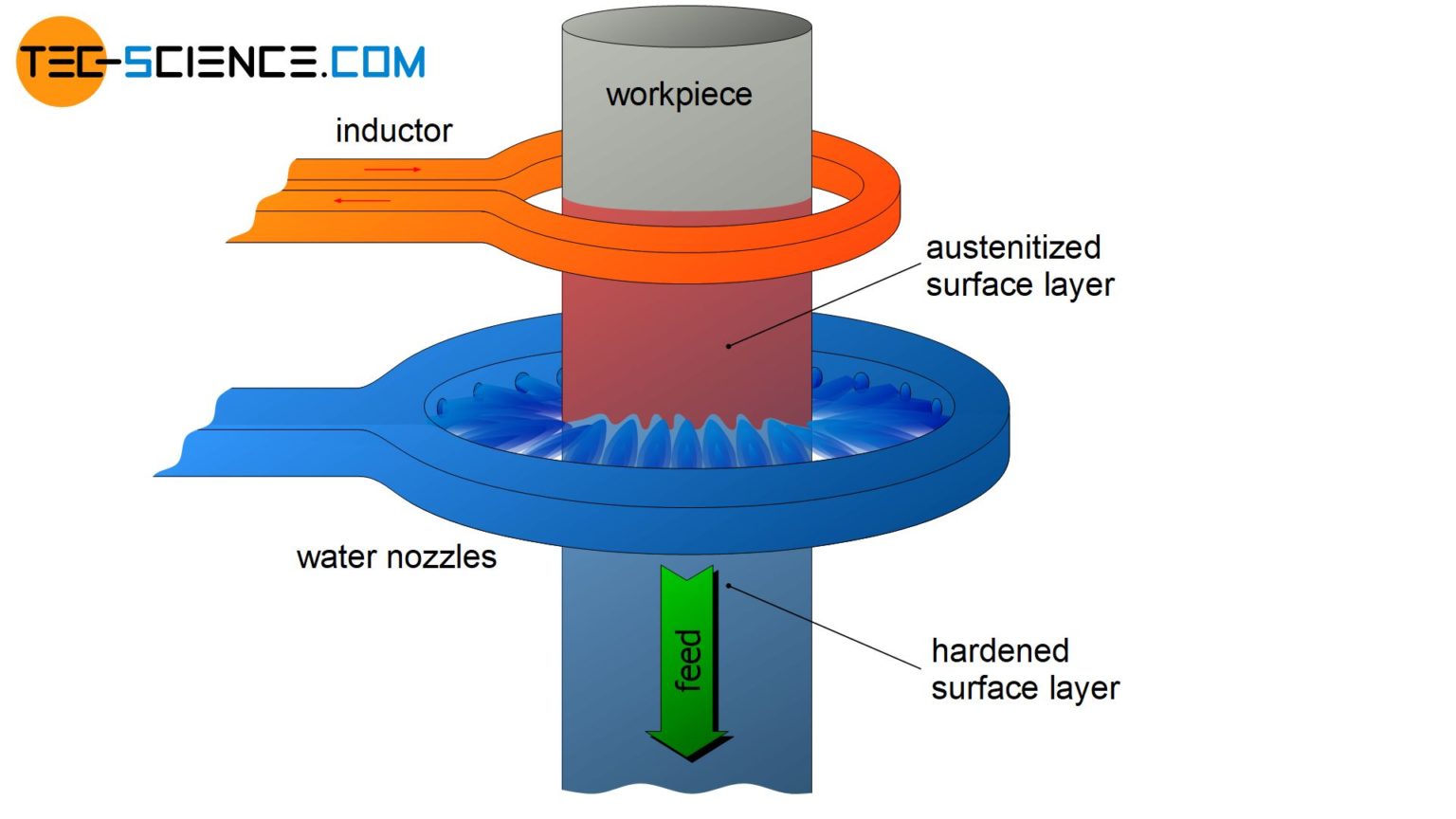

Induction Heating Induction Heat Treating Surface Process An acknowledged expert on induction hardening, kristian became managing director of efd induction sweden in 2007. in addition to writing the section on induction heating for the book ‘steel and its heat treatment—a handbook’, kristian has written and co authored numerous articles about induction hardening. Introduction induction heating is used in the industry over the past three decades. due to the rapid heating and good repro ducibility are used in applications the heat treatment. in recent years, there has been significant interest in expanding the use of induction heating process in different manufacturing process. Induction heating is a combination of several interrelated physical phenomena, including heat transfer, electromagnetics, and metallurgy. this article presents a brief review of different heat transfer modes, namely, heat conduction, thermal radiation, and convection. it focuses on the specifics of induction heating and heat treating applications. This article focuses on induction hardening process for heat treating operations specifically designed to result in proper microstructure property combinations in either localized or in the final parts. it briefly reviews the heat treating basics for conventional heat treating operations of steels with iron carbon phase and transformation diagrams.

Induction Hardening Of Steel Surface Hardening Tec Science Induction heating is a combination of several interrelated physical phenomena, including heat transfer, electromagnetics, and metallurgy. this article presents a brief review of different heat transfer modes, namely, heat conduction, thermal radiation, and convection. it focuses on the specifics of induction heating and heat treating applications. This article focuses on induction hardening process for heat treating operations specifically designed to result in proper microstructure property combinations in either localized or in the final parts. it briefly reviews the heat treating basics for conventional heat treating operations of steels with iron carbon phase and transformation diagrams.

Induction Heat Treating Surface Process In 2021 Induction Hea

Comments are closed.