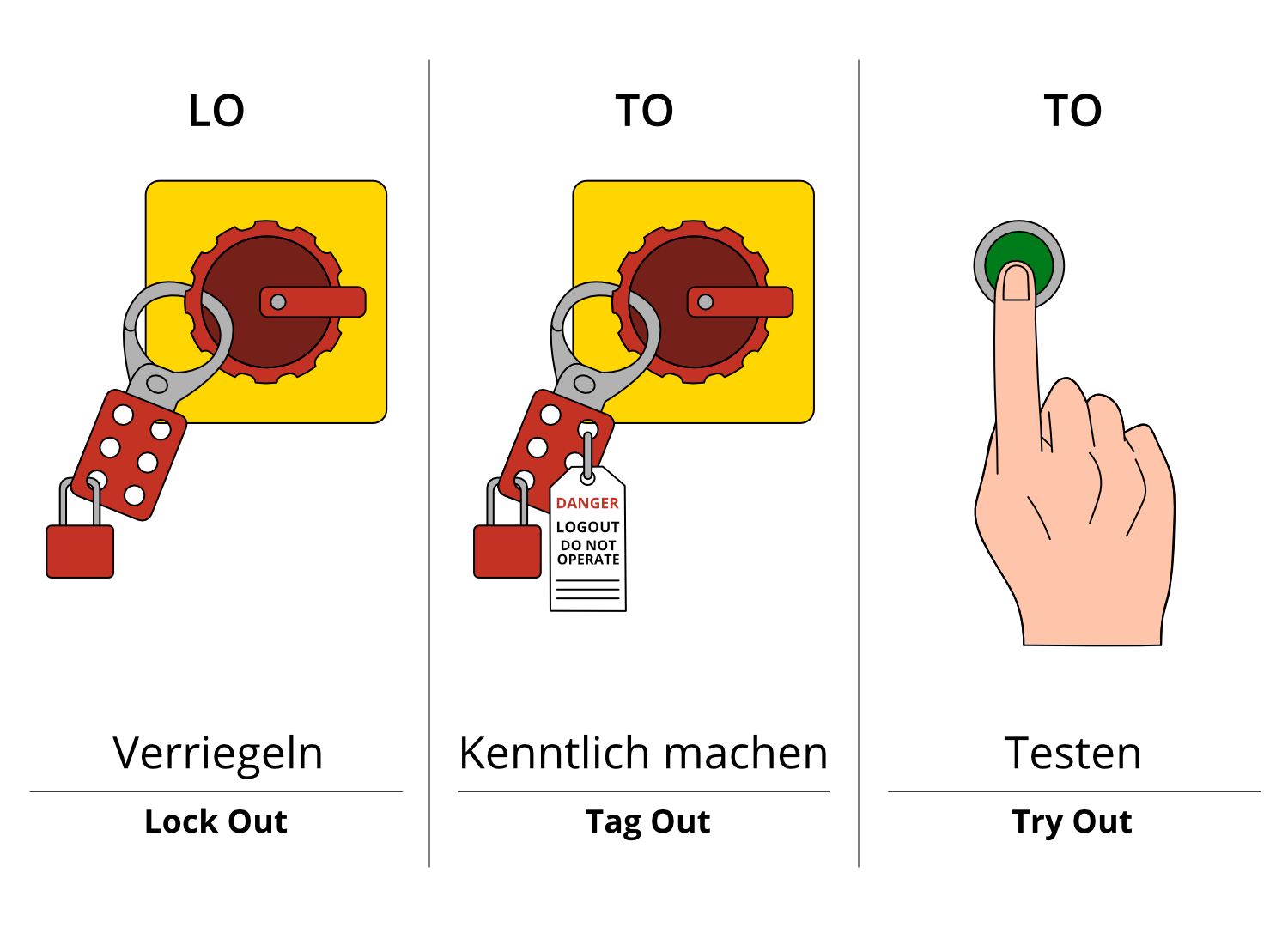

Lototo Safety Poster

Lock Out Tag Out Try Out Lototo Fгјr Mehr Arbeitssicherheit Step 1: notify affected employees. step 2: identify procedure and hazards. step 3: shut down. step 4: isolate machine from energy source. step 5: apply lockout tagout devices. step 6: check stored energy. step 7: verify isolation, tryout and test. step 8: bring equipment back on line. Lockout tagout tryout (loto) protects a worker by preventing others from turning on equipment or from a release of energy while working on or servicing equipment & machinery, working inside a grain bin, and working around conveyors and augers. loto controls hazardous energy. how does it work? the off position.

Poster Loto Lock Out Tag Our Selangor Malaysia Kuala Lumpur Kl In conclusion, lockout tagout (loto) safety training is a critical component of maintaining a safe workplace. it is essential for preventing accidents, ensuring employee safety, and complying with legal requirements. by implementing effective loto procedures and programs, employers can create a safer and more productive work environment. Removal of lototo: criteria for removing locks, tags, and isolations are established, and a controlled and monitored restart procedure ensures a safe re energizing of equipment. importance of lototo in industrial settings. lototo safety holds immense importance in industrial settings, offering: enhanced safety through the active verification step. Elevate your workplace safety standards to new heights with our in depth exploration of lockout tagout tryout, or lototo, an advanced safety procedure design. Find helpful minimum safety procedure examples at osha standards 1910.147 appendix a, the texas department of insurance, and the maine department of labor. creating an energy control program. to better implement loto procedures, create an energy control program that includes a safety plan, training, and auditing.

Lototo Procedure Gbi Van Dijk Bouw Techniek Elevate your workplace safety standards to new heights with our in depth exploration of lockout tagout tryout, or lototo, an advanced safety procedure design. Find helpful minimum safety procedure examples at osha standards 1910.147 appendix a, the texas department of insurance, and the maine department of labor. creating an energy control program. to better implement loto procedures, create an energy control program that includes a safety plan, training, and auditing. Major industries are adopting the lototo process due to the awareness and associated real life risks. it is now being recognised as best practice for safety management in quarries, oil & gas, heavy manufacturing, food processing plants and more. sectors such as renewable energy, waste and large retail companies are beginning to apply company wide. The lock out, tag out, try out (lototo) procedure has long been considered one of the safest ways to isolate equipment prior to maintenance work or repairs taking place. the procedure is integral for protecting employees and outside contractors from accidental re energization of equipment, and potential injury or fatalities.

What Is Loto Lockout Tagout In Workplace Safety Major industries are adopting the lototo process due to the awareness and associated real life risks. it is now being recognised as best practice for safety management in quarries, oil & gas, heavy manufacturing, food processing plants and more. sectors such as renewable energy, waste and large retail companies are beginning to apply company wide. The lock out, tag out, try out (lototo) procedure has long been considered one of the safest ways to isolate equipment prior to maintenance work or repairs taking place. the procedure is integral for protecting employees and outside contractors from accidental re energization of equipment, and potential injury or fatalities.

Comments are closed.