Maintenance Pr Ventive Et Corrective By Roazi Ael

Maintenance Pr Ventive Et Corrective By Roazi Ael Epuration eau potable hvac 4 5 3 6 2 pompe 7 1 0 moteur describe a process: how does it all come together? add your content how about some visuals? text videos images symbols where?. Corrective maintenance is the reactive side of maintenance strategies, focusing on addressing and repairing equipment after a failure occurs. unlike preventive measures that schedule maintenance tasks ahead of time, corrective maintenance steps in when issues are detected or systems break down, aiming to quickly resolve problems and restore.

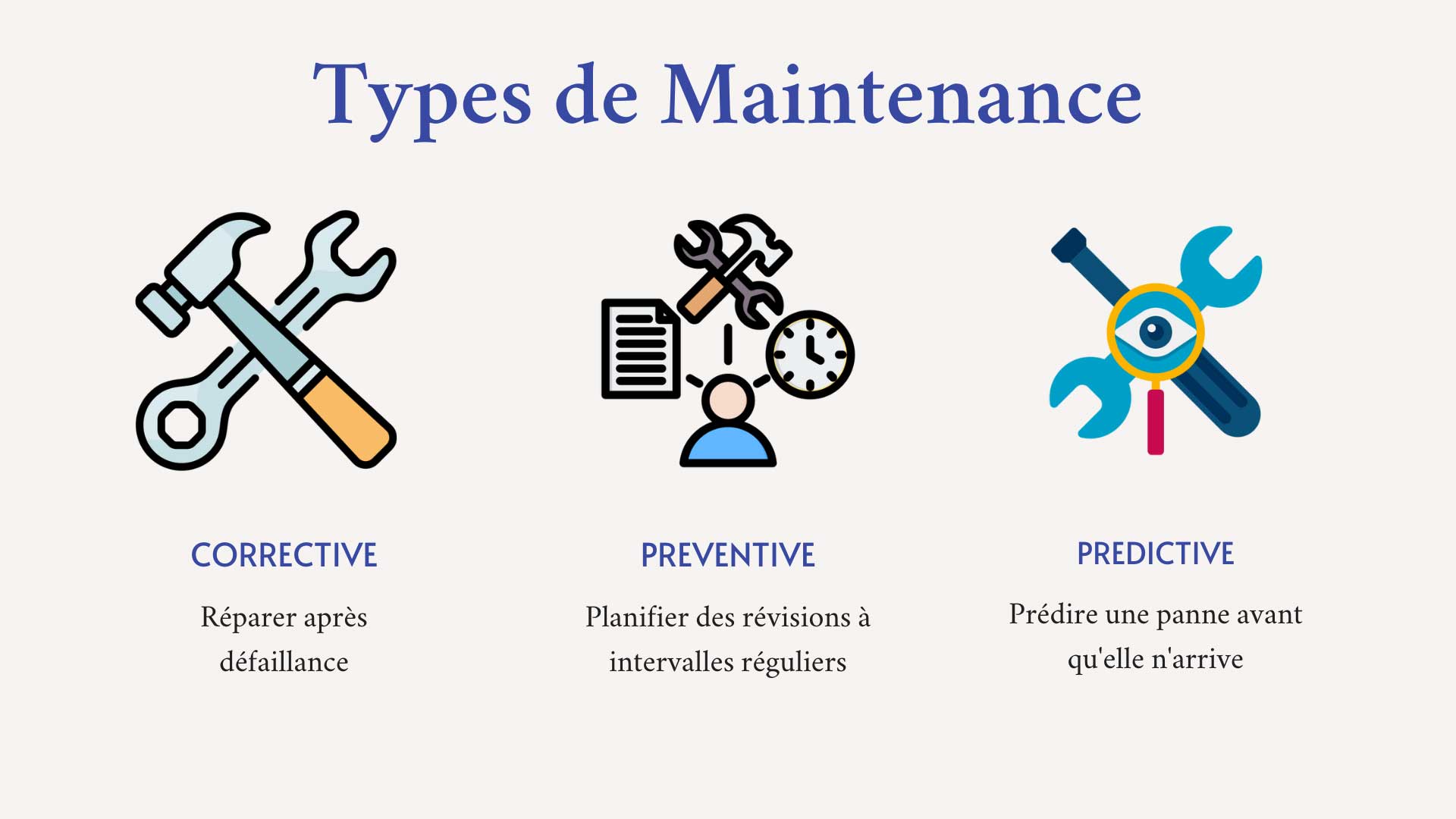

Maintenance Prг Dictive Des Opportunitг S Pour L Industrie Appel d'offre n°13 joue 005311462024 : maintenance préventive, corrective et réparation de portes, portails, rideaux, barrières et bornesautomatiques ou semi automatiques de la ville d'ivry sur seine. Corrective maintenance can be defined as a maintenance task performed to identify, isolate, and rectify a fault so that the failed equipment, machine, or asset can be restored to an operational condition within the tolerances or limits established for in service operations. corrective maintenance is maintenance which is carried out after failure detection and is aimed…. Nce split between preventive maintenance and corrective maintenance.preventive maintenance is done before a failure occurs and consists of maintenance types like: time based maintenance, failure finding maintenance, risk based. maintenance, condition based maintenance and predictive maintenance.corrective maintenance is done after a failure has. Where the cost of part failure and repair is less than the preventive or predictive maintenance costs, corrective maintenance is often the best solution. so, for example, in the case of our light bulb, corrective is certainly the best option as the cost and time taken to replace the bulb is unlikely to dramatically impact budgets or work.

Corrective Versus Preventive Maintenance Maintenance Services Direct Nce split between preventive maintenance and corrective maintenance.preventive maintenance is done before a failure occurs and consists of maintenance types like: time based maintenance, failure finding maintenance, risk based. maintenance, condition based maintenance and predictive maintenance.corrective maintenance is done after a failure has. Where the cost of part failure and repair is less than the preventive or predictive maintenance costs, corrective maintenance is often the best solution. so, for example, in the case of our light bulb, corrective is certainly the best option as the cost and time taken to replace the bulb is unlikely to dramatically impact budgets or work. Maintenance, repair, and operations (mro) is the foundational support for facilities and equipment. it includes regular maintenance work, precision repairs, and comprehensive refurbishments of machinery systems – a spectrum of tasks necessary to ensure constant operation within the industry. the role that mro plays is critical. E maintenance.d’opérer des. de prévoir des améliorations. on retrouve toutes ces informations dans un tableau exemple : historique de maintenance corrective et préventive equipement : type : machine : numéro : xécutés type d’interventionannée :tempscoût a chaque intervention de maintenance un compte rendu est réalisé indiquant les.

Maintenance Preventive Predictive Proactive Corrective Maintenance, repair, and operations (mro) is the foundational support for facilities and equipment. it includes regular maintenance work, precision repairs, and comprehensive refurbishments of machinery systems – a spectrum of tasks necessary to ensure constant operation within the industry. the role that mro plays is critical. E maintenance.d’opérer des. de prévoir des améliorations. on retrouve toutes ces informations dans un tableau exemple : historique de maintenance corrective et préventive equipement : type : machine : numéro : xécutés type d’interventionannée :tempscoût a chaque intervention de maintenance un compte rendu est réalisé indiquant les.

Comments are closed.