Materials Free Full Text Thermo Compression Bonding Of Cu Snag

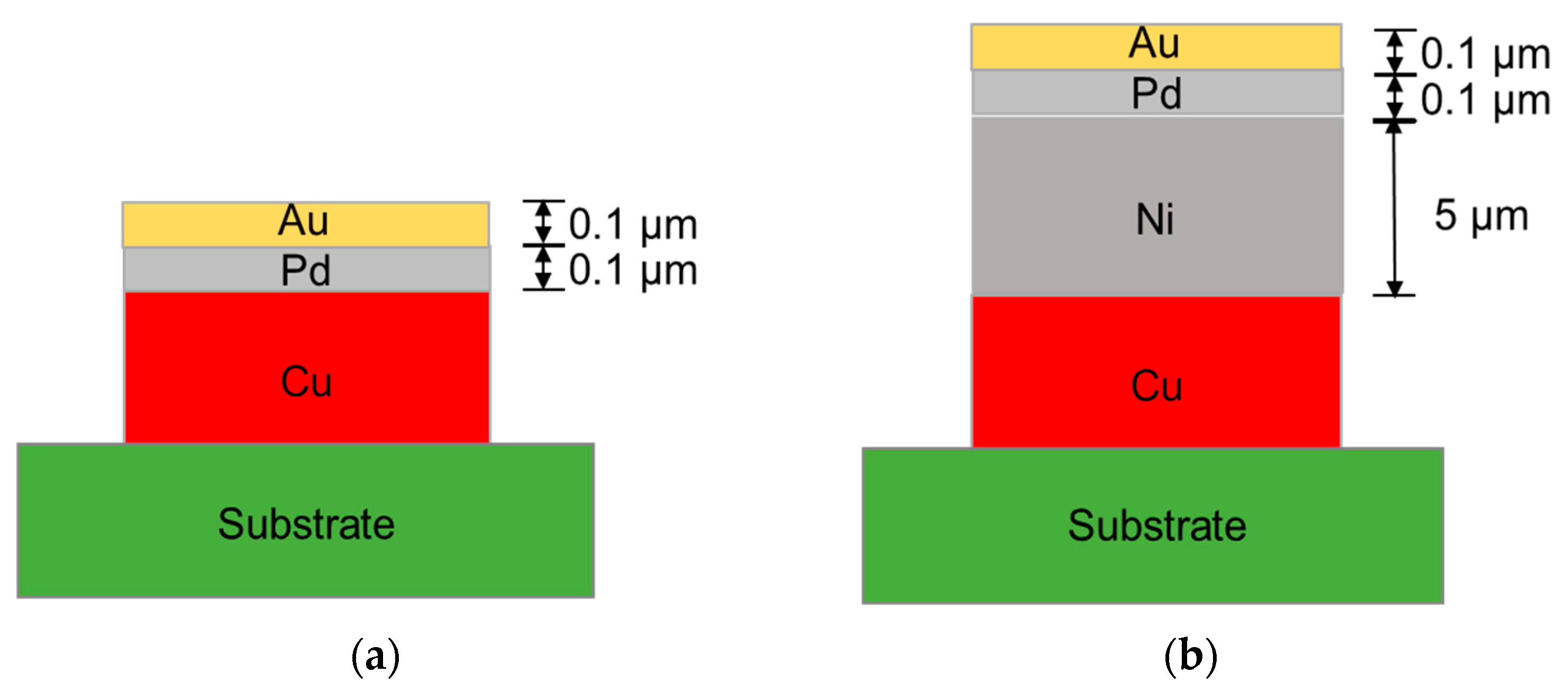

Materials Free Full Text Thermo Compression Bonding Of Cu Snag Thermo compression bonding (tcb) properties of cu snag pillar bumps on electroless palladium immersion gold (epig) were evaluated in this study. a test chip with cu snag pillar bumps was bonded on the surface finished cu pads with the tcb method. the surface roughness of the epig was 82 nm, which was 1.6 times higher than that of the enepig surface finish because the epig was so thin that it. Search text. search type . add circle outline "thermo compression bonding of cu snag pillar bumps with electroless palladium immersion gold (epig) surface finish.

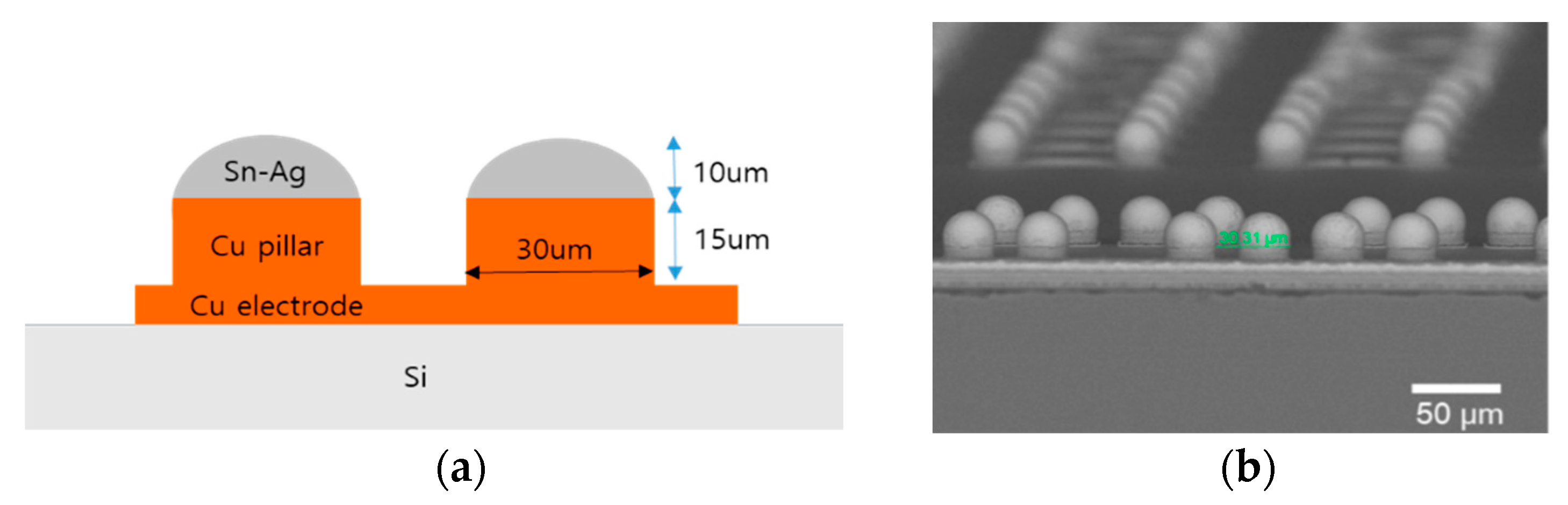

Materials Free Full Text Thermo Compression Bonding Of Cu Snag To read the full text of this research, you can request a copy directly from the authors. two bonding schemes, cu ni snag–cu and cu ni snag–cu ni snag, and two sizes of bumps, 100 μm and. For the stretch type joint of snag snag bonding scheme, similar to the cu snag bonding configuration, under the bonding temperature of 300 °c and 325 °c, solder stripping and necking happened almost in all joints, and even in a few joints under the bonding temperature of 350 °c, as shown in fig. 10a, and it was obvious that the bottom solder. Thermo compression bonding of cu snag pillar bumps with electroless palladium immersion gold (epig) surface finish download full text pdf read full text. materials 2023, 16, 1739. https:. The joint properties and reliability of cu snag pillar joints via a low temperature thermo compression bonding (lt tcb) process below the melting temperature of snag solder were investigated in this study. the bonding temperature was 150 °c. the pitches of the cu snag pillar bumps were 40 and 60 μm.

Materials Free Full Text Thermo Compression Bonding Of Cu Snag Thermo compression bonding of cu snag pillar bumps with electroless palladium immersion gold (epig) surface finish download full text pdf read full text. materials 2023, 16, 1739. https:. The joint properties and reliability of cu snag pillar joints via a low temperature thermo compression bonding (lt tcb) process below the melting temperature of snag solder were investigated in this study. the bonding temperature was 150 °c. the pitches of the cu snag pillar bumps were 40 and 60 μm. The joint properties and reliability of cu snag pillar joints via a low temperature thermo compression bonding (lt tcb) process below the melting temperature of snag solder were investigated in this study. the bonding temperature was 150 °c. the pitches of the cu snag pillar bumps were 40 and 60 μm. Doi: 10.1016 j.mee.2019.04.030 corpus id: 164229023; joint properties and reliability of cu sn ag pillar bumps via low temperature thermo compression bonding @article{park2019jointpa, title={joint properties and reliability of cu sn ag pillar bumps via low temperature thermo compression bonding}, author={jae yong park and ja yeon lee and hwan pil park and sung chul kim and tae young lee and.

Materials Free Full Text Thermo Compression Bonding Of Cu Snag The joint properties and reliability of cu snag pillar joints via a low temperature thermo compression bonding (lt tcb) process below the melting temperature of snag solder were investigated in this study. the bonding temperature was 150 °c. the pitches of the cu snag pillar bumps were 40 and 60 μm. Doi: 10.1016 j.mee.2019.04.030 corpus id: 164229023; joint properties and reliability of cu sn ag pillar bumps via low temperature thermo compression bonding @article{park2019jointpa, title={joint properties and reliability of cu sn ag pillar bumps via low temperature thermo compression bonding}, author={jae yong park and ja yeon lee and hwan pil park and sung chul kim and tae young lee and.

Materials Free Full Text Thermo Compression Bonding Of Cu Snag

Comments are closed.