Optimizing Ventilation In Power Plants With Cfd

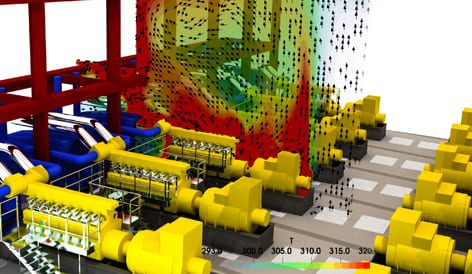

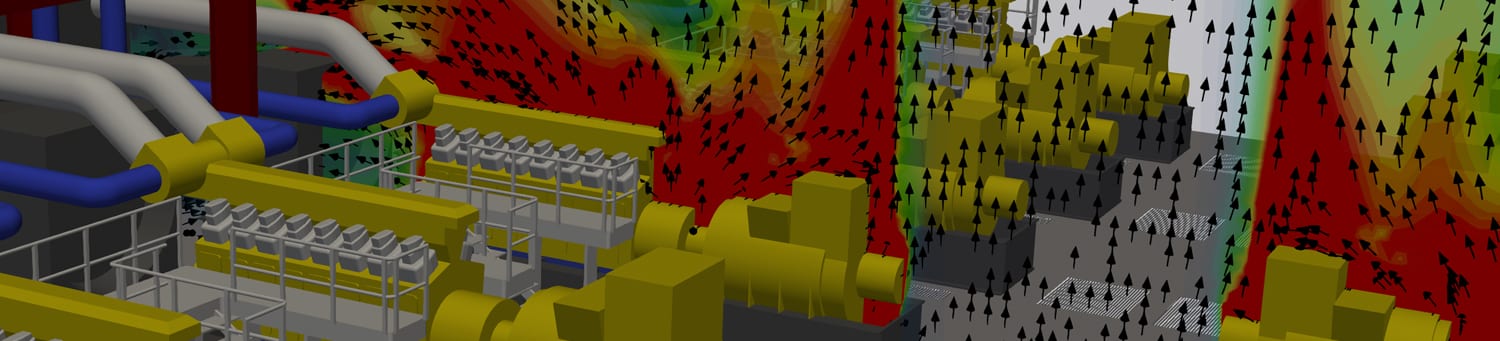

Optimizing Ventilation In Power Plants With Cfd Youtube The ventilation concept of a diesel engine power plant will be taken as an example. by participating, you will learn: how to get easy, cost efficient access to cfd simulation; how to use cfd to investigate the hvac system in a power plant; how to identify the best cooling strategy for engine power plants to ensure energy efficiency and reduce costs. When designing an engine room, it is essential to keep temperatures down with the lowest possible cost of ventilation. in order to ensure the reliability and.

Optimizing Ventilation In Power Plants With Cfd Simscale An air intake system (the green section pictured above) is an important part of a power plant gas turbine since a high drop in pressure leads to a drop in turbine’s gross power output. optimizing the ventilation system design is an increasingly challenging process as both the layout complexity and the range of features that can be included in the intake system expands. 1. conventional design with sharp corners at the bend. 2. optimized design with blades (guide vanes) at the bend. 3. optimized design with blades and rounded corners at the bend. ventilation. In this 30 minute demo, we take a look at how cloud based flow simulation can help engineers to design better ventilation systems. we reduce the pressure dro. This paper investigates the ventilation and heat dissipation performance of a 110 kv indoor substation under natural ventilation conditions using computational fluid dynamics (cfd). the objectives are to evaluate the influences of air inlet design parameters including location and size, and transformer load, on the airflow distribution, temperature field, and cooling efficiency.

Optimizing Ventilation In Power Plants With Cfd Simscale In this 30 minute demo, we take a look at how cloud based flow simulation can help engineers to design better ventilation systems. we reduce the pressure dro. This paper investigates the ventilation and heat dissipation performance of a 110 kv indoor substation under natural ventilation conditions using computational fluid dynamics (cfd). the objectives are to evaluate the influences of air inlet design parameters including location and size, and transformer load, on the airflow distribution, temperature field, and cooling efficiency. Keeping the above design objectives in mind, a three dimensional cfd analysis has been carried out using a leading commercial code to analyze the effectiveness of ge ms5002e ventilation system. a detailed geometric model is developed by including the entire turbine casing, various pipelines, surfaces of inlet and exhaust plenums, roof (with ventilation air inlets and outlet) and walls. For ventilation system design and optimization, jiao et al. (2019a) proposed seven different layouts of dilution ventilation systems. using cfd simulation, the effectiveness of the layouts were.

How To Optimize Ventilation Systems Design With Cfd Simulation Youtube Keeping the above design objectives in mind, a three dimensional cfd analysis has been carried out using a leading commercial code to analyze the effectiveness of ge ms5002e ventilation system. a detailed geometric model is developed by including the entire turbine casing, various pipelines, surfaces of inlet and exhaust plenums, roof (with ventilation air inlets and outlet) and walls. For ventilation system design and optimization, jiao et al. (2019a) proposed seven different layouts of dilution ventilation systems. using cfd simulation, the effectiveness of the layouts were.

Why Optimize Your Ventilation System Design With Cfd

Comments are closed.