Pcb Edge Plating Plating Pcb Design Edges

Edge Plating Pcb Edge Plating Pcb Castellation A Tech Pcb edge plating is the process of applying a metallic coating to the exposed copper connections along the edges of a printed circuit board (pcb) to facilitate electrical connections. this metallic coating is often called edge plating, castellation, or side plating. the copper edge plating extends from the top to the bottom surfaces of a pcb. To apply edge plating in the pcb layout, the plating needs to be defined using polygon pour. the polygon pour can then be run up to the edge of the pcb. the typical practice in ecad software is to further extend the copper pour over the edge of the pcb. the copper plating extension distance over the edge can be small, typically by the 20 mil 0.

Pcb Design Instructions For Edge Plating 4. selective edge plating can be applied to pads surrounding rectangular slots if the pads have at least 2mm spacing, as indicated in purple above. 5. if all four edges of the pcb are plated, 3 to 4 short segments (at least 3mm spacing) must be left unplated to allow for panel support tabs, for example at the positions marked a, b, c, and d above. The process of pcb edge plating involves several steps. it typically begins with the preparation of the pcb edges by cleaning, etching, and applying a thin layer of seed material, such as copper. the seed layer acts as a base for subsequent electroplating. then, an electroplating process is employed, where the pcb edges are immersed in an. Pcb edge plating, also known as pcb edge plating or edge metallization, is a specialized process used in the manufacturing of printed circuit boards (pcbs). this technique involves applying a layer of metal, typically copper, to the edges of a pcb. the purpose of pcb edge plating is to enhance the conductivity, durability, and electromagnetic. Pcb edge plating is the process of plating exposed copper connections along the edges of a printed circuit board with a metallic coating like gold or tin to facilitate electrical connections. this article provides a comprehensive overview of pcb edge plating including its purpose, edge connector types, plating processes, inspection, reliability.

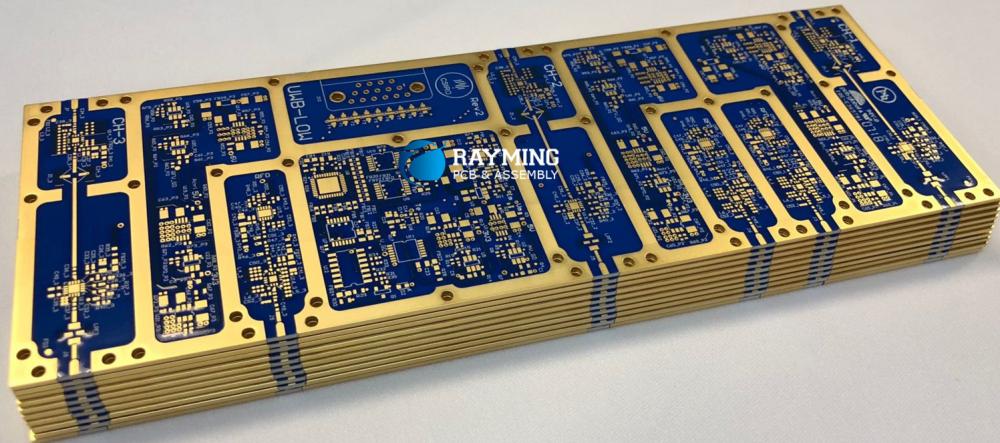

What Is Pcb Edge Plating Rayming Pcb Pcb edge plating, also known as pcb edge plating or edge metallization, is a specialized process used in the manufacturing of printed circuit boards (pcbs). this technique involves applying a layer of metal, typically copper, to the edges of a pcb. the purpose of pcb edge plating is to enhance the conductivity, durability, and electromagnetic. Pcb edge plating is the process of plating exposed copper connections along the edges of a printed circuit board with a metallic coating like gold or tin to facilitate electrical connections. this article provides a comprehensive overview of pcb edge plating including its purpose, edge connector types, plating processes, inspection, reliability. The thickness of pcb edge plating can vary depending on the specific requirements of the application and the design of the pcb. however, typical thicknesses for pcb edge plating range from about 1 to 25 microns (0.001 to 0.025 millimeters). Pcb edge plating provides additional noise suppression and improves emc. this video provides some practical tips for creating metalized pcb edges in altium d.

Comments are closed.