Pharmaceutical Industry And Unit Process

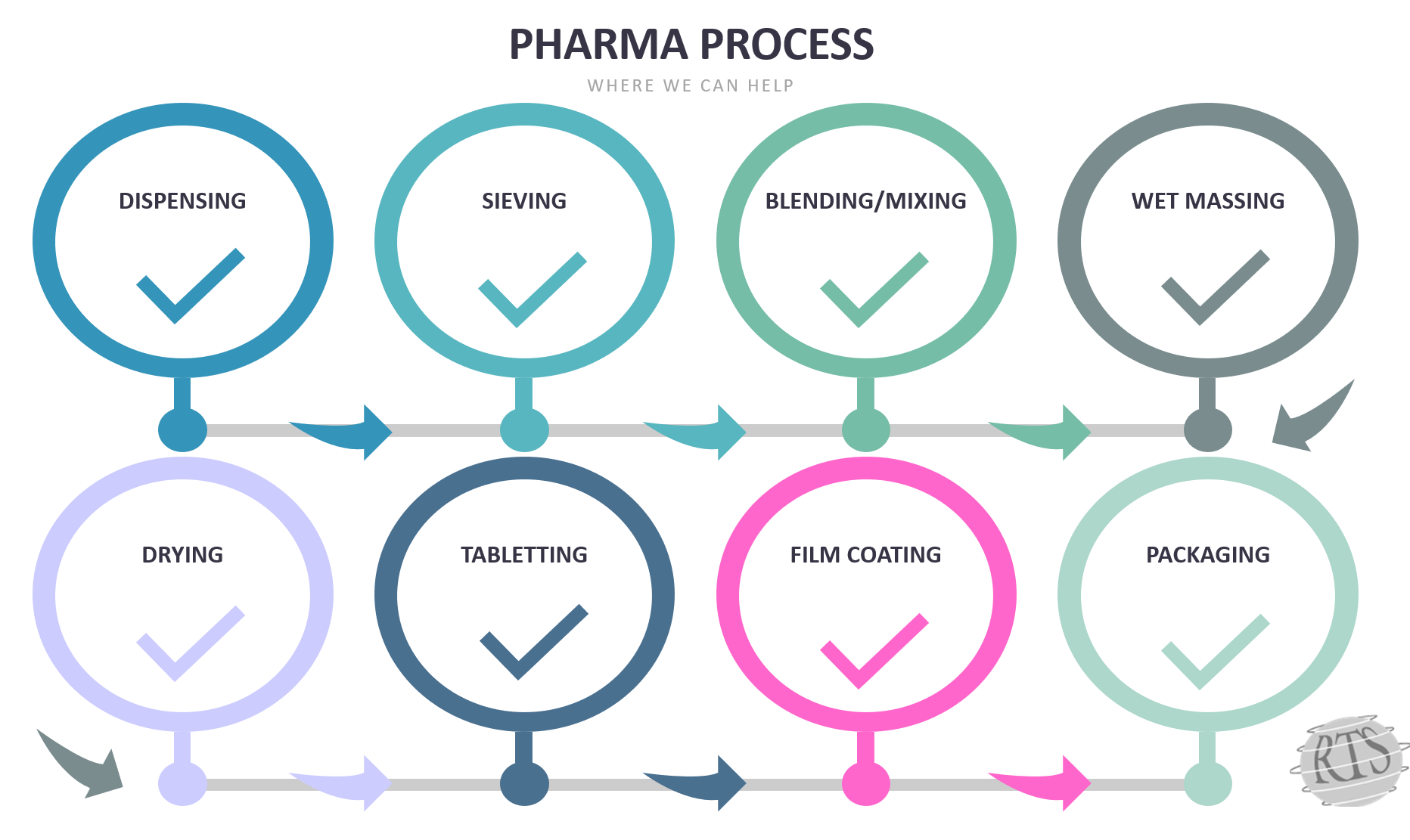

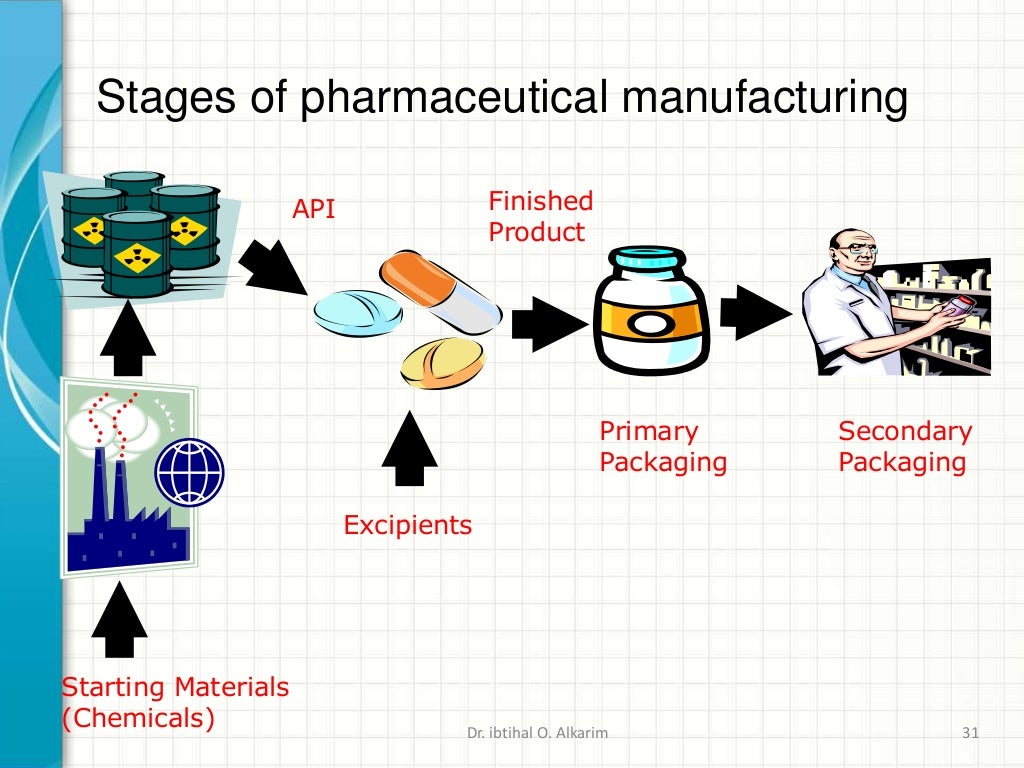

Pharma Process Overview Pharmaceutical manufacturing is the process of industrial scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. the process of drug manufacturing can be broken down into a series of unit operations , such as milling , granulation , coating , tablet pressing , and others. Pharmaceutical industry and unit process. pharmaceutical manufacturing involves the industrial scale synthesis and processing of drug products. key steps include active pharmaceutical ingredient (api) synthesis, combining apis and excipients, and processing the mixture into solid oral dosage forms like tablets through unit operations such as.

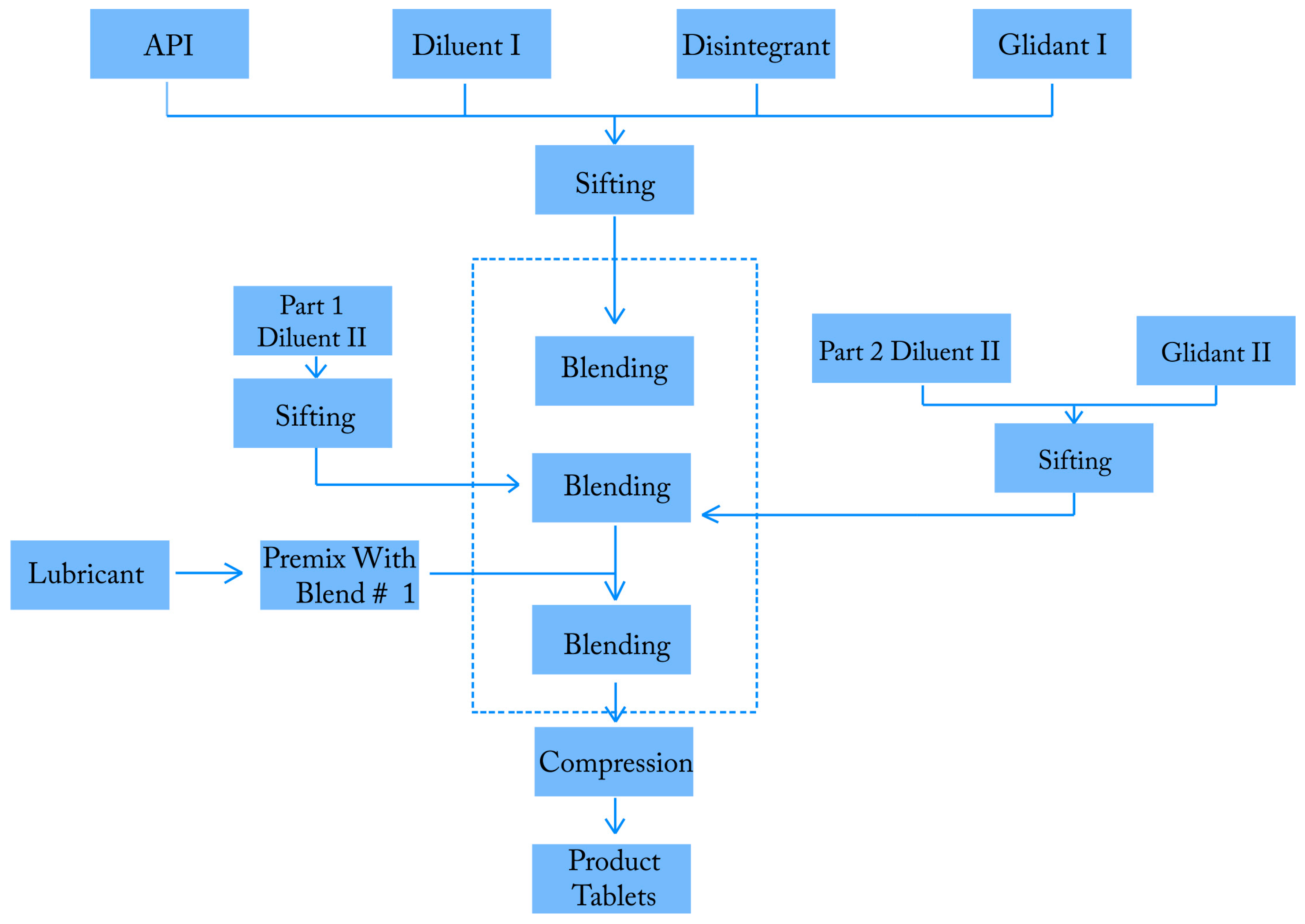

Pharmaceutical Industry And Unit Process Abstract. pharmaceutical industry unit operations are a subset of the unit operations that are encountered in the chemical process industry. although the materials being processed are different. Pdf. this handbook features contributions from a team of expert authors representing the many disciplines within science, engineering, and technology that are involved in pharmaceutical manufacturing. they provide the information and tools you need to design, implement, operate, and troubleshoot a pharmaceutical manufacturing system. The pharmaceutical manufacturing process is typically made up of a combination of specific unit processes chosen according to the physical and chemical characteristics of the active pharmaceutical ingredient. dry granulation: compaction of a low density powder to a granule. the roller compaction process consists of screw feed, compaction, and. Building a new facility can cost up to $2 billion and take 5 to 10 years. expanding existing facilities, transferring a single product to a new manufacturing site or retrofitting an existing facility for a new product can take several years. as large scale manufacturing processes are developed, companies develop plans for sourcing all the.

Pharmaceutic Isometric Infographic 484540 Vector Art At Vecteezy The pharmaceutical manufacturing process is typically made up of a combination of specific unit processes chosen according to the physical and chemical characteristics of the active pharmaceutical ingredient. dry granulation: compaction of a low density powder to a granule. the roller compaction process consists of screw feed, compaction, and. Building a new facility can cost up to $2 billion and take 5 to 10 years. expanding existing facilities, transferring a single product to a new manufacturing site or retrofitting an existing facility for a new product can take several years. as large scale manufacturing processes are developed, companies develop plans for sourcing all the. 1.1 introduction. continuous manufacturing has been receiving increasing attention in the pharmaceutical industry driven by the expectation of achieving reduced operating and capital costs, improved product quality, and increased reliability (lee et al. 2015 ). while this mode of manufacture is new to the pharmaceutical industry, it is widely. By analogy with the chemical process industries in which efficiency considerations have driven the integration of reactor separator unit operations, such as reactive distillation and reactive extraction, the pharmaceutical industry is developing new combinations of unit operations that have enhanced performance and efficiency.

Manufacturing Process Control 1.1 introduction. continuous manufacturing has been receiving increasing attention in the pharmaceutical industry driven by the expectation of achieving reduced operating and capital costs, improved product quality, and increased reliability (lee et al. 2015 ). while this mode of manufacture is new to the pharmaceutical industry, it is widely. By analogy with the chemical process industries in which efficiency considerations have driven the integration of reactor separator unit operations, such as reactive distillation and reactive extraction, the pharmaceutical industry is developing new combinations of unit operations that have enhanced performance and efficiency.

Comments are closed.