Pid Control Of Main Engine Jacket Cooling System Youtube

Jacket Water Cooling System Of Main Engine Marine Diesel Engine Use of pid control of main engine jacket cooling system. Animated description of pid control of engine jacket cooling system.

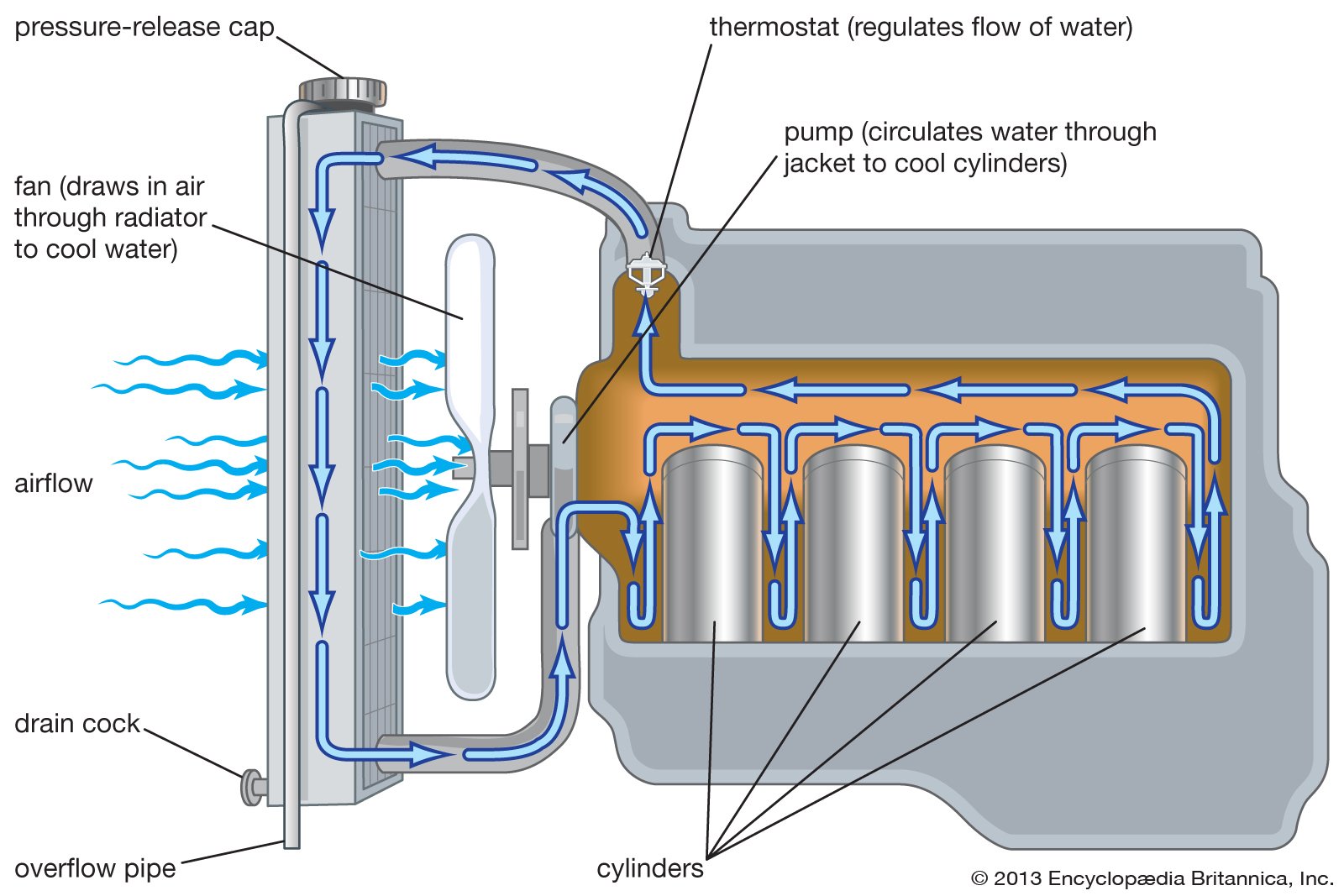

Pid Control Of Main Engine Jacket Cooling System Youtube Cooling medium is fresh water or sea water, in new ships central cooling systems are used, where fresh water as a cooling medium. circulating pump: there are two jacket water circulating pumps used onboard with a discharge pressure of 3 4 bars. the circulating pump takes suction from the deaeration tank to the main engine. Pid controller working principle. the working principle behind a pid controller is that the proportional, integral and derivative terms must be individually adjusted or "tuned." based on the difference between these values a correction factor is calculated and applied to the input. for example, if an oven is cooler than required, the heat will. Basic principles of pid controllers. automatic controllers are used onboard ships for the adjustment of one or more parameters in a system. function of the controller is to maintain the parameter as per desired value (value set by the operator). the parameter could be jacket water temperature (for engine jacket water cooling system. Open main engine jacket cooling water inlet and outlet to the evaporator gradually. open the air vent clock at the top of the evaporator to make sure the evaporator is filled with jacket cooling water. air must be purged out if any. switch on the salinity alarm panel for measuring purity of the freshwater produced.

Chevy 2 5 Engine Cooling Diagram Basic principles of pid controllers. automatic controllers are used onboard ships for the adjustment of one or more parameters in a system. function of the controller is to maintain the parameter as per desired value (value set by the operator). the parameter could be jacket water temperature (for engine jacket water cooling system. Open main engine jacket cooling water inlet and outlet to the evaporator gradually. open the air vent clock at the top of the evaporator to make sure the evaporator is filled with jacket cooling water. air must be purged out if any. switch on the salinity alarm panel for measuring purity of the freshwater produced. The simple reason to maintain such a high temperature while the main engine is not running is to avoid cold corrosion and thermal shocks when the main engine is started. a pid controller is fitted in this system so that the main engine jacket water outlet temperature is always maintained around 88 90℃. note:. A piping and instrumentation diagram (p&id) shows the piping, equipment, instrumentation, and process flow of a main engine cooling system and viscosity control system. a p&id uses standard symbols to represent system components and shows their interconnectivity. it provides important details for engineers to design, construct, operate, and modify the physical process. a p&id of a main engine.

Comments are closed.