Pin On 3d Printed Gears

Pin On 3d Printed Gears Assembly instructions: (read in full before starting) 1. clean up the gear teeth with a razor blade so they will mesh smoothly then place them on the plate in the same rotational orientation they were when you printed them. (the pin on the sun gear is to the right and the handle of the ring gear is top and center.) 2. Test no.2 – backlash. next, for testing the backlash and strength of the gears, we will use the following setup. one gear will be fixed with 4 bolts, and the other will be able to rotate with two bearings attached to it. the gears have a module of 2.5 and they are all 3d printed with the same settings.

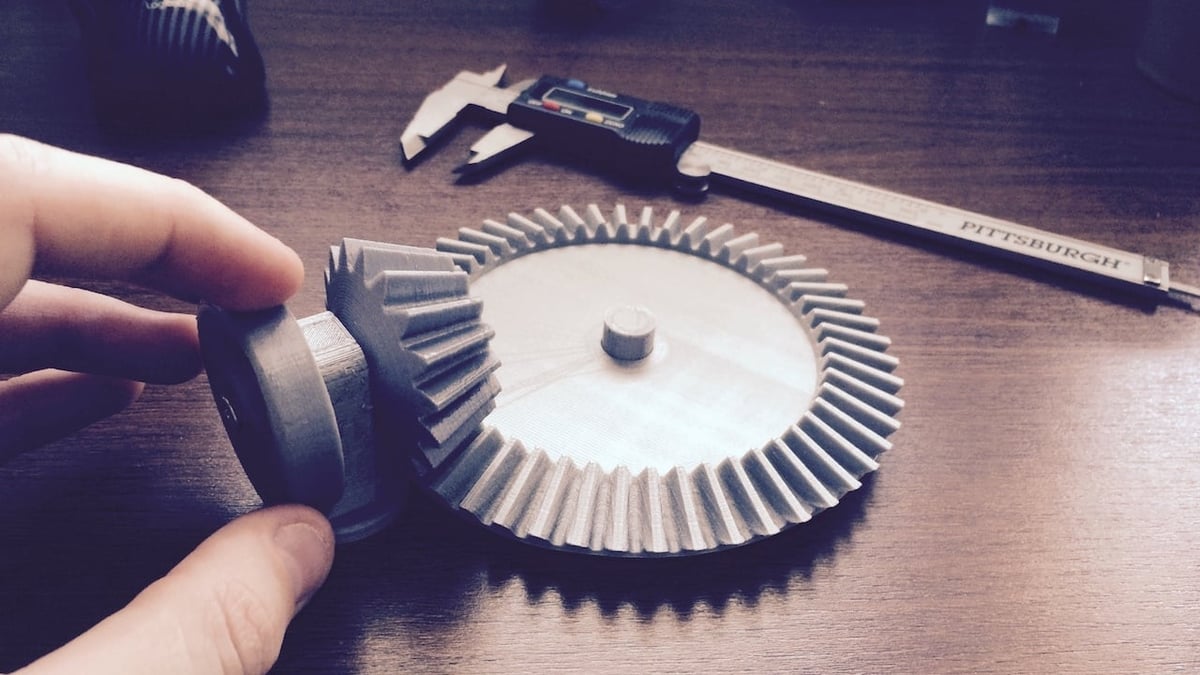

3d Printed 4 Different Ways How To Connect Gears Test Gears By Let S While bevel gears can be 3d printed for fun and practical uses, their most common uses aren’t ideal for 3d printing as the heat generated by high speeds is too much for most filaments to handle. this means you’re unlikely to be using 3d printed gears for any kind of high pressure task. rack and pinion gears. download: thingiverse; designer. When designing a gear, you need to determine the maximum and minimum number of teeth that your 3d printer can handle. this test model will help you check your 3d printer’s capabilities from pitch values of 12 up to 48. reducing the number of teeth and using bigger teeth on your gears seems like a simple solution. Ideally, you could spend a bit more time to create a threaded cap to ensure they don’t fly off, and then you’d have a nice 3d printed gear toy. to create the first riser, i’ll offset the base of the pin to 10mm for the larger gear. i’ll then offset the pin of the smaller gear 5mm. My design uses a 3d printed fixture with a v grooved filament path and a pivoting gear axle made out of clevis pins. the pins are ground down to fit 5mm and 8mm drive gears. the cross drilled holes through both pins have the same spacing, so using one hole as a pivot point and the opposite hole to hang a weight from provides a consistent force.

3d Printed Gears How To Make Them All3dp Ideally, you could spend a bit more time to create a threaded cap to ensure they don’t fly off, and then you’d have a nice 3d printed gear toy. to create the first riser, i’ll offset the base of the pin to 10mm for the larger gear. i’ll then offset the pin of the smaller gear 5mm. My design uses a 3d printed fixture with a v grooved filament path and a pivoting gear axle made out of clevis pins. the pins are ground down to fit 5mm and 8mm drive gears. the cross drilled holes through both pins have the same spacing, so using one hole as a pivot point and the opposite hole to hang a weight from provides a consistent force. 2. nylon. nylon is perhaps the most popular choice for 3d printing gears at home, and it is one of the best choices out of the mainstream and affordable filaments on the market. this material is strong and flexible, and has high heat resistance, meaning it can perform without deforming at temperatures of up to 120°c. Firstly, take your 3d printer for a test drive. gears are simple, but the teeth can present a challenge with the wrong 3d printer settings. you must determine the best settings for your 3d printer, which also applies to your materials. try printing a test gear and putting it into use to see if your printer’s tolerances produce accurate gears.

Pin On 3d Printing 2. nylon. nylon is perhaps the most popular choice for 3d printing gears at home, and it is one of the best choices out of the mainstream and affordable filaments on the market. this material is strong and flexible, and has high heat resistance, meaning it can perform without deforming at temperatures of up to 120°c. Firstly, take your 3d printer for a test drive. gears are simple, but the teeth can present a challenge with the wrong 3d printer settings. you must determine the best settings for your 3d printer, which also applies to your materials. try printing a test gear and putting it into use to see if your printer’s tolerances produce accurate gears.

Pro Design Tips And Software For 3d Printed Gears

Comments are closed.