Pin On Class

Push Pin On Class Text Stock Photo Alamy Class z pin gages has an allowed deviation of .0001″, geometry of .00005″, finish 8 micro inch ra. class x pin gages has an allowed deviation of .00004″, geometry of .00002″, finish 4 micro inch ra. class xx pin gages has an allowed deviation of .00002″, geometry of .00001″, finish 2 micro inch ra. meyer gage company manufactures. Each time you generate a class pin, your students can enjoy 14 fun packed days of all of our game modes—and they can play these games alone, in groups, or with friends. your students can use the class pin feature to study in their own time, recap what they’ve already learned, work on out of class assignments, and prepare for tests or classes.

Pin On Class Reunion Freeprintable Me Class pin – control i o pins. See our website for class x pin gages. class y gages: these gages are available with an inch tolerance of .000070" and a metric tolerance of .00178mm. these gages are used where moderate precision is needed. (note: tolerances vary as the diameter range changes, please see the tolerance table below for tolerance listings from .010" thru 12.010. Tolerance calculator for plain cylindrical i.d. & o.d. gages. In conclusion, proper placement of pins on army uniforms is essential in maintaining a professional appearance and adhering to uniform regulations. understanding the different types of pins, following step by step guidelines, and regularly maintaining the uniform's appearance and accuracy are crucial for every soldier.

Pin On Class Basics Tolerance calculator for plain cylindrical i.d. & o.d. gages. In conclusion, proper placement of pins on army uniforms is essential in maintaining a professional appearance and adhering to uniform regulations. understanding the different types of pins, following step by step guidelines, and regularly maintaining the uniform's appearance and accuracy are crucial for every soldier. This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. gages. input data and result are rounded to 8 decimal places. suggested gage tolerance is calculated using the 10% product tolerance rule. related resources:. Plug gage measuring the art of using pre sized precision metal plugs to determine the acceptability of diameters of drilled or machined holes the difference between any class of gage is not the wear or life span of the gage, it's the tolerance which is allowed in the manufacturing process of the gage.

Pin On English Classes This calculator will determine the gage class and tolerance per ansi asme b89.1.5 for cylindrical i.d and o.d. gages. input data and result are rounded to 8 decimal places. suggested gage tolerance is calculated using the 10% product tolerance rule. related resources:. Plug gage measuring the art of using pre sized precision metal plugs to determine the acceptability of diameters of drilled or machined holes the difference between any class of gage is not the wear or life span of the gage, it's the tolerance which is allowed in the manufacturing process of the gage.

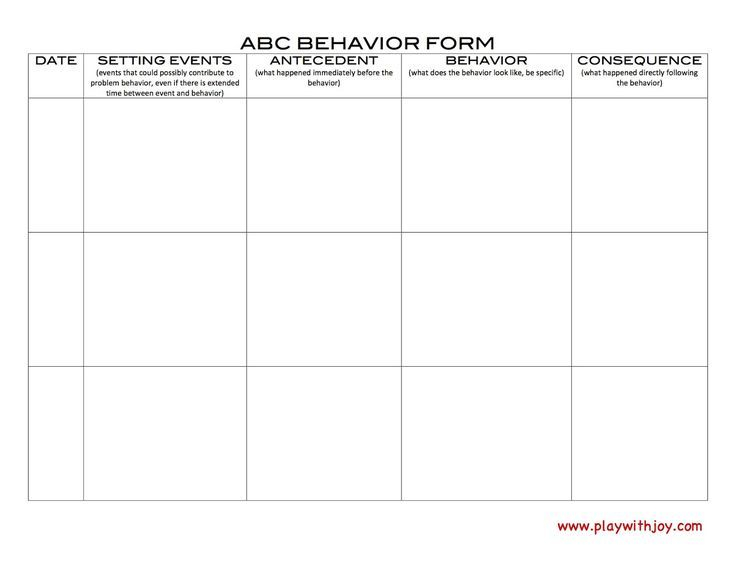

Pin On Class Room Management Printablebehaviorchart

Comments are closed.