Pneumatic Cylinder Principles Types Application

Aventics Hydraulic Cylinder Manufacturers A pneumatic cylinder is a special type device that uses the energy created by compressed gas to create a force for alternating linear motion. since that “pneuma” is the greek word for air, a pneumatic cylinder may also be called an air cylinder. a force is applied into the piston, pushing it in the desired direction, very much like. Telescopic cylinder. both single acting and double acting cylinders are available in telescopic type but widely used in hydraulic applications in high load handling. such as heavy cranes, dumpers, etc., pneumatic telescopic cylinders are rarely used, not discussed more in detail in this article.

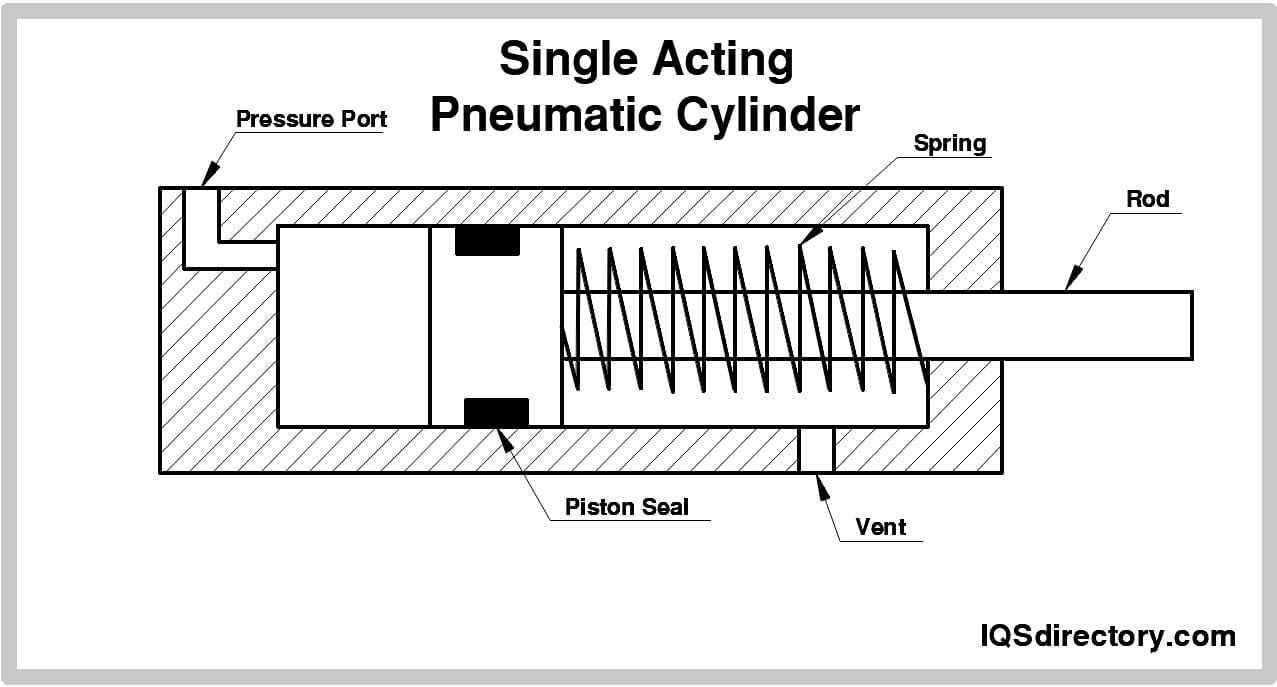

Pneumatic Cylinder Principles Types Application 45 Off A pneumatic cylinder may also be known as an air cylinder or a pneumatic actuator. they are mechanical components that are used to produce power or movement from the air or compressed gas. they are a cheap, cost effective way to produce linear or rotary motion. pneumatic cylinders can also be known as pneumatic actuators or pneumatic drives. Principle, types, specifications, and applications. a pneumatic cylinder is also known as an air cylinder or pneumatic actuator. it is a mechanical device that utilizes compressed air to produce linear motion or force. it is a common component in many industrial automation applications requiring controlled movement or force. January 10, 2018 by charles kolstad. figure 1: pneumatic cylinder. a pneumatic cylinder converts compressed air energy into a reciprocating linear motion. they are simple to use and are a cost efficient solution to move loads linearly, making them commonly used in the automation of machines and industrial processes. Pneumatic cylinder, also known as air cylinder, is a mechanical device which uses the power of compressed gas to produce a force in a reciprocating linear motion. [ 1]: 85. like in a hydraulic cylinder, something forces a piston to move in the desired direction. the piston is a disc or cylinder, and the piston rod transfers the force it.

What Is A Pneumatic Cylinder What Are The Types Of Pneumatic Cylinder January 10, 2018 by charles kolstad. figure 1: pneumatic cylinder. a pneumatic cylinder converts compressed air energy into a reciprocating linear motion. they are simple to use and are a cost efficient solution to move loads linearly, making them commonly used in the automation of machines and industrial processes. Pneumatic cylinder, also known as air cylinder, is a mechanical device which uses the power of compressed gas to produce a force in a reciprocating linear motion. [ 1]: 85. like in a hydraulic cylinder, something forces a piston to move in the desired direction. the piston is a disc or cylinder, and the piston rod transfers the force it. Double acting pneumatic cylinder. note the pressure ports at both the right and left ends of the barrel. image used courtesy of the author . working principle of pneumatic actuators. the types of pneumatic cylinders discussed above have different working principles. here we will analyze the working principle of each type of cylinder. This type controls the piston’s motions and works in both directions. the only downside of double acting is that it consumes more energy and does a complicated operation that is unsuitable for applications needing a cylinder to remain in a particular position. additionally, it has more stroke length and force. 5 types of pneumatic cylinder.

Pneumatic Cylinder Principles Types Application 45 Off Double acting pneumatic cylinder. note the pressure ports at both the right and left ends of the barrel. image used courtesy of the author . working principle of pneumatic actuators. the types of pneumatic cylinders discussed above have different working principles. here we will analyze the working principle of each type of cylinder. This type controls the piston’s motions and works in both directions. the only downside of double acting is that it consumes more energy and does a complicated operation that is unsuitable for applications needing a cylinder to remain in a particular position. additionally, it has more stroke length and force. 5 types of pneumatic cylinder.

Comments are closed.