Pressure Testing Of Double End Rod Hydraulic Cylinder

Pressure Testing Of Double End Rod Hydraulic Cylinder Youtube Pressure testing of double end rod hydraulic cylinder is very important. double end rod hydraulic cylinder is often used in various construction machinery, m. Test procedure the procedure for conducting the test is as follows: secure the cylinder with its service ports up. fill both sides of the cylinder with clean hydraulic fluid through its service ports. connect ball valves (1) and (2), gauges (3) and (4), relief valve (5) and directional control valve (6) as shown in figure 1. with ball valves (1.

100 Pressure Testing Hydraulic Cylinder For Ship Dock Shipyard The cylinder pressure test, designed to test the integrity of the piston seal and welds in hydraulic cylinders, pressurizes the cylinder during operation. once the pressure has been applied, the cylinder is inspected for signs of leakage past the seal or welded parts. this process also performs a “end of stroke bypass test”, and is a good. The holding pressure is measured to ensure it remains steady at full pressure. the rod is fully retracted and the technician checks the gauges to ensure they are steady at this stage, as well. the cylinder must be able to reach a holding pressure of at least 3000 psi to ensure there are no leaks. every cylinder has a maximum pressure (burst. Parkerxrefbu2. standard test procedure for hydraulic cylinders. function test. once the cylinder is placed on the test stand and hydraulic lines attached, the cylinder will be cycled its full stroke a minimum of three (3) full cycles. the cylinder will be rejected if it functions erratically. erratic function is excessive chatter, slapstrick. Having adjusted the relief valve to back out, the direct flow will be made to the cylinder’s rod side. start increasing the setting of the relief valve until the rated pressure is displayed on the gauge. close the ball valve and center the directional control valve. keep in mind that the hydraulic power unit used in the test has protection.

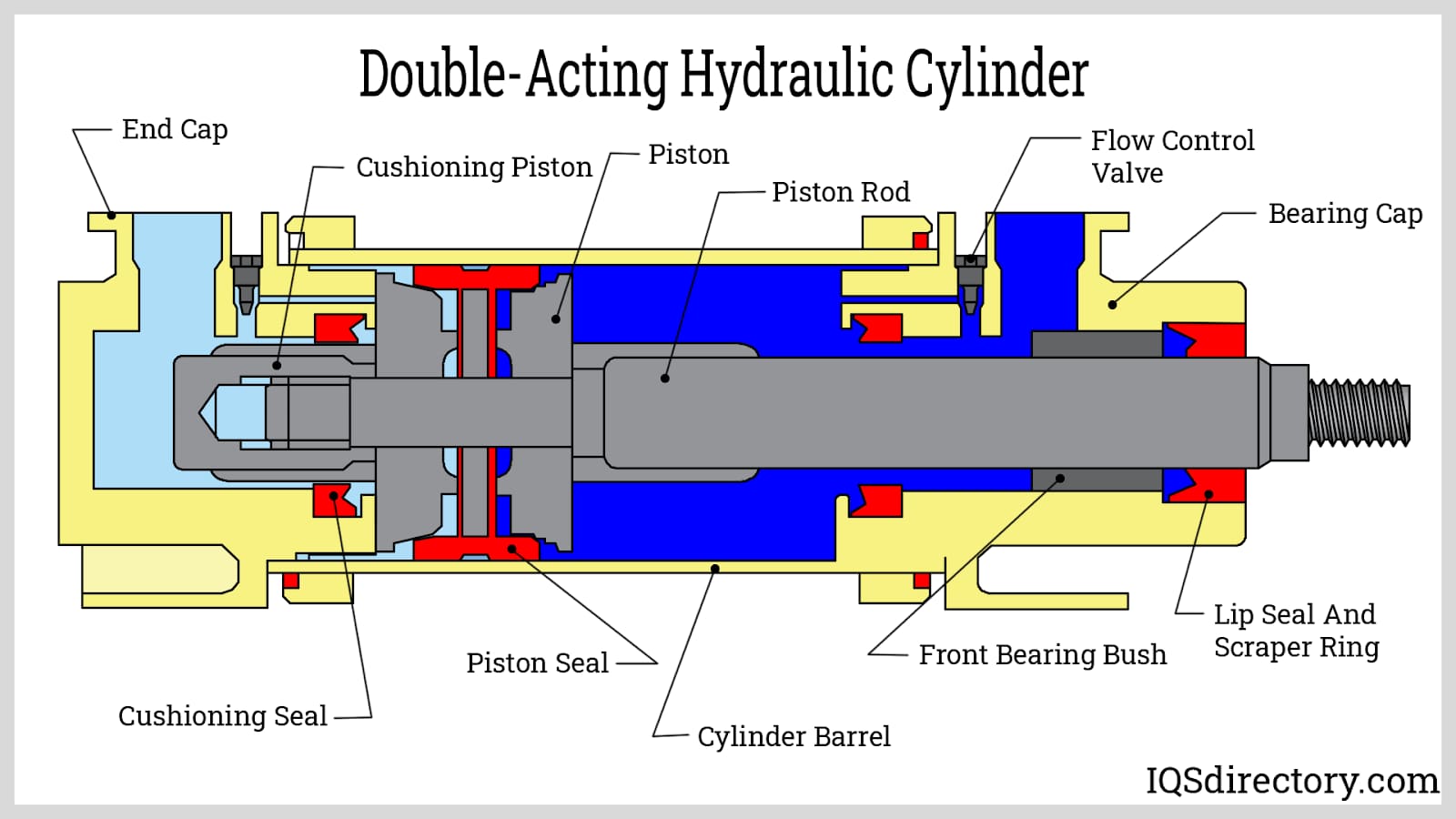

Hydraulic Cylinders Parkerxrefbu2. standard test procedure for hydraulic cylinders. function test. once the cylinder is placed on the test stand and hydraulic lines attached, the cylinder will be cycled its full stroke a minimum of three (3) full cycles. the cylinder will be rejected if it functions erratically. erratic function is excessive chatter, slapstrick. Having adjusted the relief valve to back out, the direct flow will be made to the cylinder’s rod side. start increasing the setting of the relief valve until the rated pressure is displayed on the gauge. close the ball valve and center the directional control valve. keep in mind that the hydraulic power unit used in the test has protection. Test procedure. the procedure for conducting the test is as follows: secure the cylinder with its service ports up. fill both sides of the cylinder with clean hydraulic fluid through its service ports. connect ball valves (1) and (2), gauges (3) and (4), relief valve (5) and directional control valve (6) as shown in figure 1. This means that if the piston side is pressurized to 3,000 psi a pressure of 6,000 psi will be required on the rod side to produce an equal force. this is why pressure intensification can occur in a double acting cylinder. note that pressurizing a cylinder rated at 3,000 psi, to 6,000 psi, can have devastating consequences.

Hydraulic Cylinders Their Applications Hydrastore Hydraulic Systems Test procedure. the procedure for conducting the test is as follows: secure the cylinder with its service ports up. fill both sides of the cylinder with clean hydraulic fluid through its service ports. connect ball valves (1) and (2), gauges (3) and (4), relief valve (5) and directional control valve (6) as shown in figure 1. This means that if the piston side is pressurized to 3,000 psi a pressure of 6,000 psi will be required on the rod side to produce an equal force. this is why pressure intensification can occur in a double acting cylinder. note that pressurizing a cylinder rated at 3,000 psi, to 6,000 psi, can have devastating consequences.

Skb 6u Roto Rack Case With W E Us 97 40 Npcriminaldefence

Comments are closed.