Rapid Control Prototype Experiment Compared With Traditional Methods

Rapid Control Prototype Experiment Compared With Traditional Methods Download scientific diagram | rapid control prototype experiment compared with traditional methods. from publication: development of manipulator digital twin experimental platform based on rcp. Rapid prototyping is best leveraged early in the design process when form and fit are being evaluated. as the design matures, traditional prototyping or production intent processes are used to create fully functional prototypes and pre production versions. rapid prototyping process. the process of creating a rapid prototype generally follows.

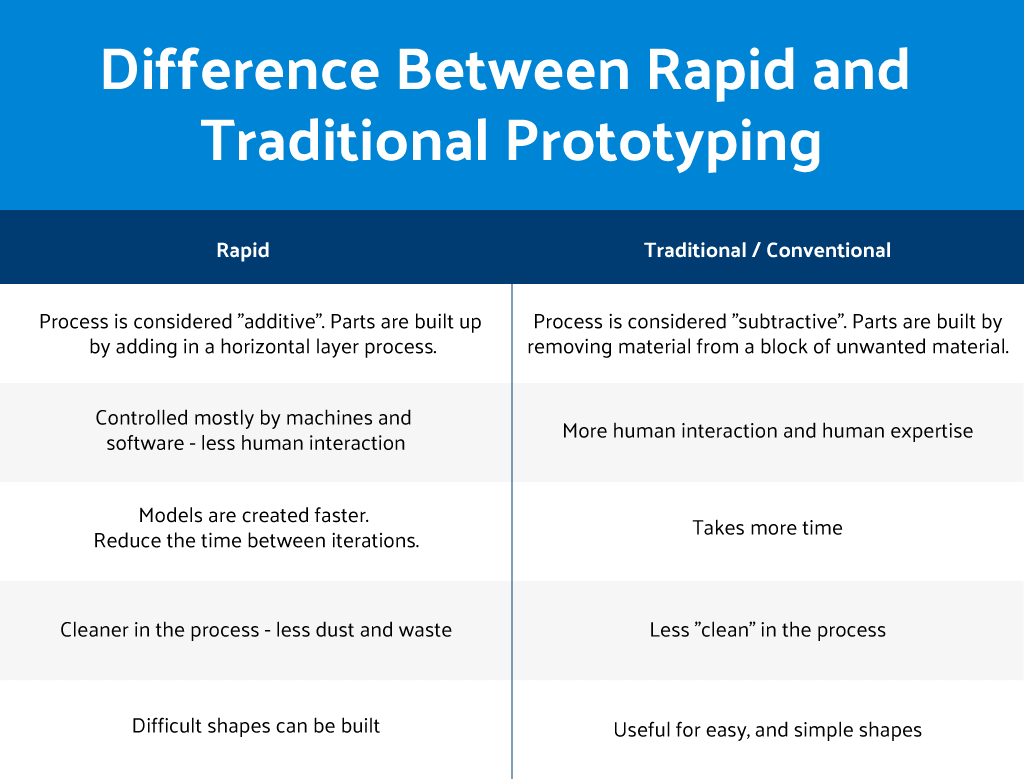

Traditional Vs Rapid Prototyping Process Youtube 2. prototyping vs. traditional methods. unlike traditional product development, which may involve lengthy design cycles and extensive documentation, rapid prototyping emphasizes swift iterations and real time feedback. it accelerates the time from concept to prototype, fostering agility and adaptability in the development process. 3. key. Cost considerations\. traditional manufacturing methods often require significant upfront investment in tooling and molds, making them more suitable for large scale production. in contrast, rapid prototyping eliminates the need for costly tooling, making it more economical for low volume or customized production runs. Unlike traditional manufacturing methods, rapid prototyping, when coupled with 3d printing, allows for immediate adjustments and implementation of feedback and test results. the outcome is a design process that fosters innovation and refinement in the product, as increased experimentation with different geometries, functionalities, and materials can optimize the final part. The ability to test pcb designs quickly through rapid prototyping provides several advantages over traditional methods: faster design iteration: make changes and test new revisions in days rather than weeks. early verification: verify the pcb layout, component choice, etc. while the design concept is still flexible.

Rapid Prototyping Increasing Proficiency In Design Unlike traditional manufacturing methods, rapid prototyping, when coupled with 3d printing, allows for immediate adjustments and implementation of feedback and test results. the outcome is a design process that fosters innovation and refinement in the product, as increased experimentation with different geometries, functionalities, and materials can optimize the final part. The ability to test pcb designs quickly through rapid prototyping provides several advantages over traditional methods: faster design iteration: make changes and test new revisions in days rather than weeks. early verification: verify the pcb layout, component choice, etc. while the design concept is still flexible. Using rapid prototyping to manufacture parts to test for component fit and function can help get your product to market faster than your competition. adjustments in design, materials, size, shape, assembly, color, manufacturability, and strength can be made following the results of your testing and analysis. many rapid prototyping processes are. Here are the general steps involved in the rapid prototyping process: conceptualization: understand the problem or need. draft initial design ideas and concepts using brainstorming or other ideation techniques. design and development: develop detailed 3d models using cad (computer aided design) software.

Comments are closed.