Reinforced Concrete Beam Construction

Concrete Beam Construction Process Traditional Timber Formwork We need to calculate the max. bending moment and shear force for our governing uls load and the bending moment due to our quasi permanent load, before we can design the reinforced concrete beam. design load applied to simply supported concrete beam. uls max bending moment. m d = 54.6 k n m ⋅ l 2 8 = 334.4 k n m. What is concrete grade beam? grade beams are commonly concrete beams which are designed to act as horizontal ties between footings or pile caps. they should be reinforced with continuous reinforcement that is developed within or beyond the supported column, or be anchored within the pile cap or footings as per aci 318 14.

Design Of Reinforced Concrete R C Beams Structville To simplify construction and thereby to reduce costs, the overall dimensions of beams, b and h are almost rounded up to nearest 25 mm. design of rectangular reinforced concrete beam procedure the design of concrete beam includes the estimation of cross section dimension and reinforcement area to resist applied loads. Designing reinforced concrete beams is a multifaceted process that plays a pivotal role in the construction industry. this comprehensive guide aims to look into the intricate details of reinforced concrete beam design, providing a thorough understanding of the principles, considerations, and best practices involved. Testing of many reinforced concrete beams has shown that the average stress within the compressive zone is 0.85β 1 fc ', and the resultant location is β 1 c 2 from the face of the concrete beam, as shown in figure 5.23a. the coefficient β 1 ranges from 0.85 for fc ' ≤ 4000 psi, to 0.65 for fc ' ≥ 8000 psi (figure 5.24). Monier patented a method for embedding iron mesh in concrete flower pots in 1867, which later evolved into a method for reinforcing structural elements like beams and slabs. by the late 19th and early 20th centuries, reinforced concrete had become a widely adopted construction material, revolutionizing architecture and engineering.

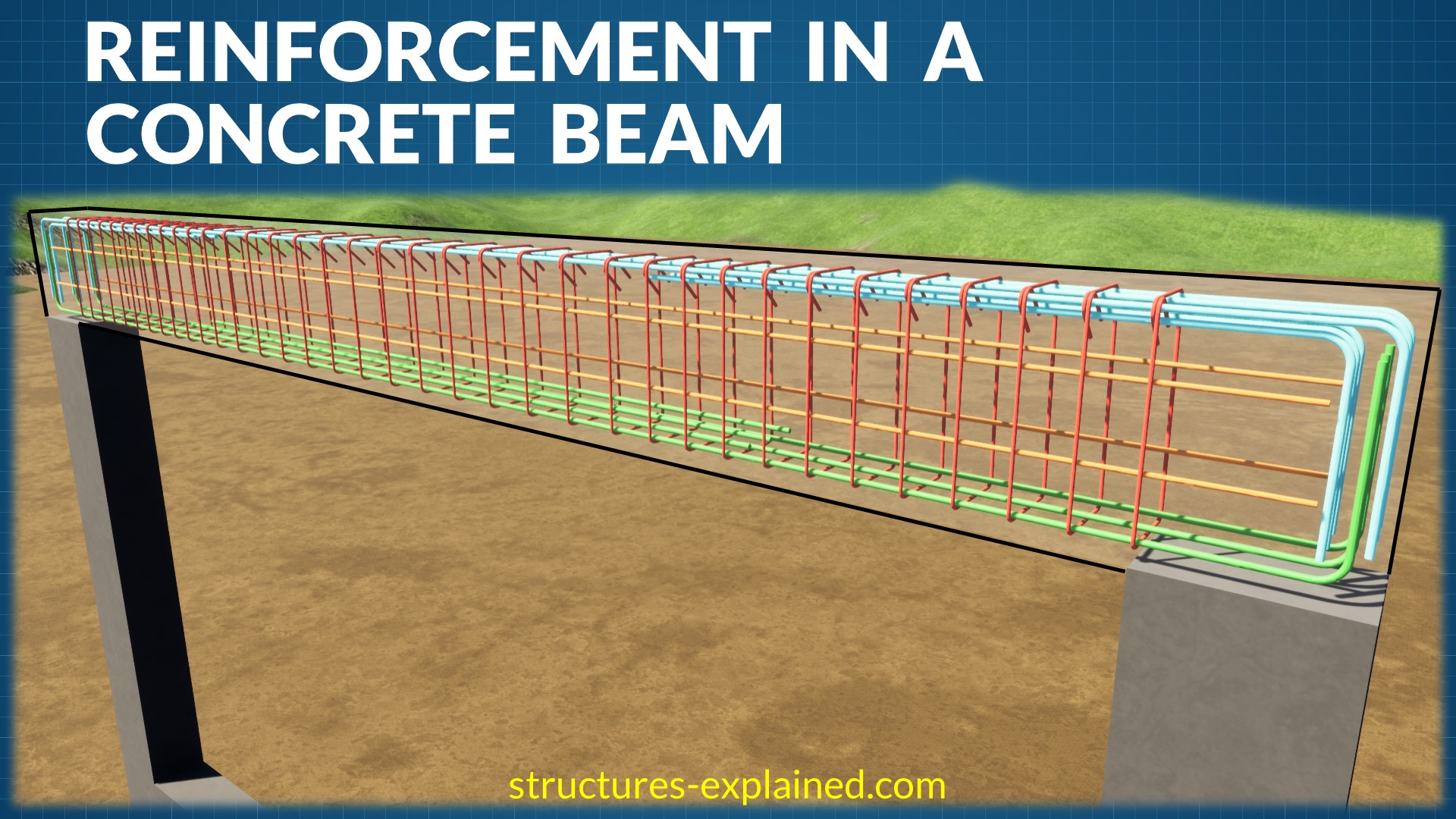

Typical Reinforcement In A Concrete Beam Beam Reinforcement Testing of many reinforced concrete beams has shown that the average stress within the compressive zone is 0.85β 1 fc ', and the resultant location is β 1 c 2 from the face of the concrete beam, as shown in figure 5.23a. the coefficient β 1 ranges from 0.85 for fc ' ≤ 4000 psi, to 0.65 for fc ' ≥ 8000 psi (figure 5.24). Monier patented a method for embedding iron mesh in concrete flower pots in 1867, which later evolved into a method for reinforcing structural elements like beams and slabs. by the late 19th and early 20th centuries, reinforced concrete had become a widely adopted construction material, revolutionizing architecture and engineering. Reinforced concrete is the common term given to a concrete member (or slab) that contains steel reinforcement (usually in the form of steel bars) to increase the strength of the structure. the material that results from the combination of concrete and reinforcing bars is called reinforced concrete (rc). during construction, the reinforcement. This edition of the reinforced concrete design handbook, sp 17m(14), is dedicated to the memory of daniel w. falconer and his many contributions to the concrete industry. he was managing director of engineering for the american concrete institute from 1998 until his death in july 2015. dan was instrumental in the reorganization of building code.

Comments are closed.