Schematics Of The First Neighbor Surrounding For Cu C Defect And Cl I

Schematics Of The First Neighbor Surrounding For Cu C Defect And Cl I The first neighbor surrounding of a substitutional cu c defect shown in on the left in figure 1 includes four regular anion sites "a" that could be occupied either by se atoms, te atoms, or a. Schematics of the first neighbor surrounding for cu c defect and (cl i cu c ) 2þ complex in a stable configuration with c3v symmetry. regular anion sites are shown in red, regular cation sites.

Schematics Of The First Neighbor Surrounding For Cu C Defect And Cl I The first neighbor surrounding of a substitutional cu c defect shown in on the left in figure 1 includes four regular anion sites “a” that could be occupied either by se atoms, te atoms, or a combination of those. since this defect exhibits full tetrahedral symmetry, the surrounding anion positions are symmetrically equivalent, so that cu c. The properties of the cu and cl related point defects in cdte effect could be illustrated using schematic drawing of two defect the first neighbor surrounding of a substitutional cu c. Segregation of charge neutral cu and cl defects at gbs. (a) cl te, (b) cl i, (c) cu i, and (d) cu cd segregations at Σ 3 (111) and te core Σ 3 (112) gbs, respectively. the lowest energy points are set as zero, the layer numbers are labeled in fig. 1, and the structural configurations are shown in fig. 7. Additionally, we have calculated the reaction mechanism of sicl 4 dissociation on the plane cucl 2 (0 0 1) with the similar cl defect and cu si bond, i.e., cl defect si cucl 2 (0 0 1); the highest energy barrier of the most favorable path (sicl 4 → sicl 3 cl( h) → sihcl 3) on the plane cl defect si cucl 2 (0 0 1) is 182.5 kj mol −1.

Schematics Of The First Neighbor Surrounding For Cu C Defect And Cl I Segregation of charge neutral cu and cl defects at gbs. (a) cl te, (b) cl i, (c) cu i, and (d) cu cd segregations at Σ 3 (111) and te core Σ 3 (112) gbs, respectively. the lowest energy points are set as zero, the layer numbers are labeled in fig. 1, and the structural configurations are shown in fig. 7. Additionally, we have calculated the reaction mechanism of sicl 4 dissociation on the plane cucl 2 (0 0 1) with the similar cl defect and cu si bond, i.e., cl defect si cucl 2 (0 0 1); the highest energy barrier of the most favorable path (sicl 4 → sicl 3 cl( h) → sihcl 3) on the plane cl defect si cucl 2 (0 0 1) is 182.5 kj mol −1. The calculations suggest that the p doping of cdte could be enhanced by forming the defect complexes of cl te −v cd. download : download full size image; fig. 3. calculated band structures and partial densities of states corresponding to (a) the ideal bulk of cdte and the defects of (b) v cd, (c) cl te and (d) cl te −v cd. the vertical. The parameters d 0, α and r 0 for cu c interaction are 0.1 ev, 1.7 Å −1 and 2.2 Å, respectively [34], it is also applied in the study of the mechanical behavior nanocrystalline cu sic composites [22]. for cu si, d 0, α and r 0 are 0.194 ev, 1.37 Å −1 and 2.5 Å, respectively [35].

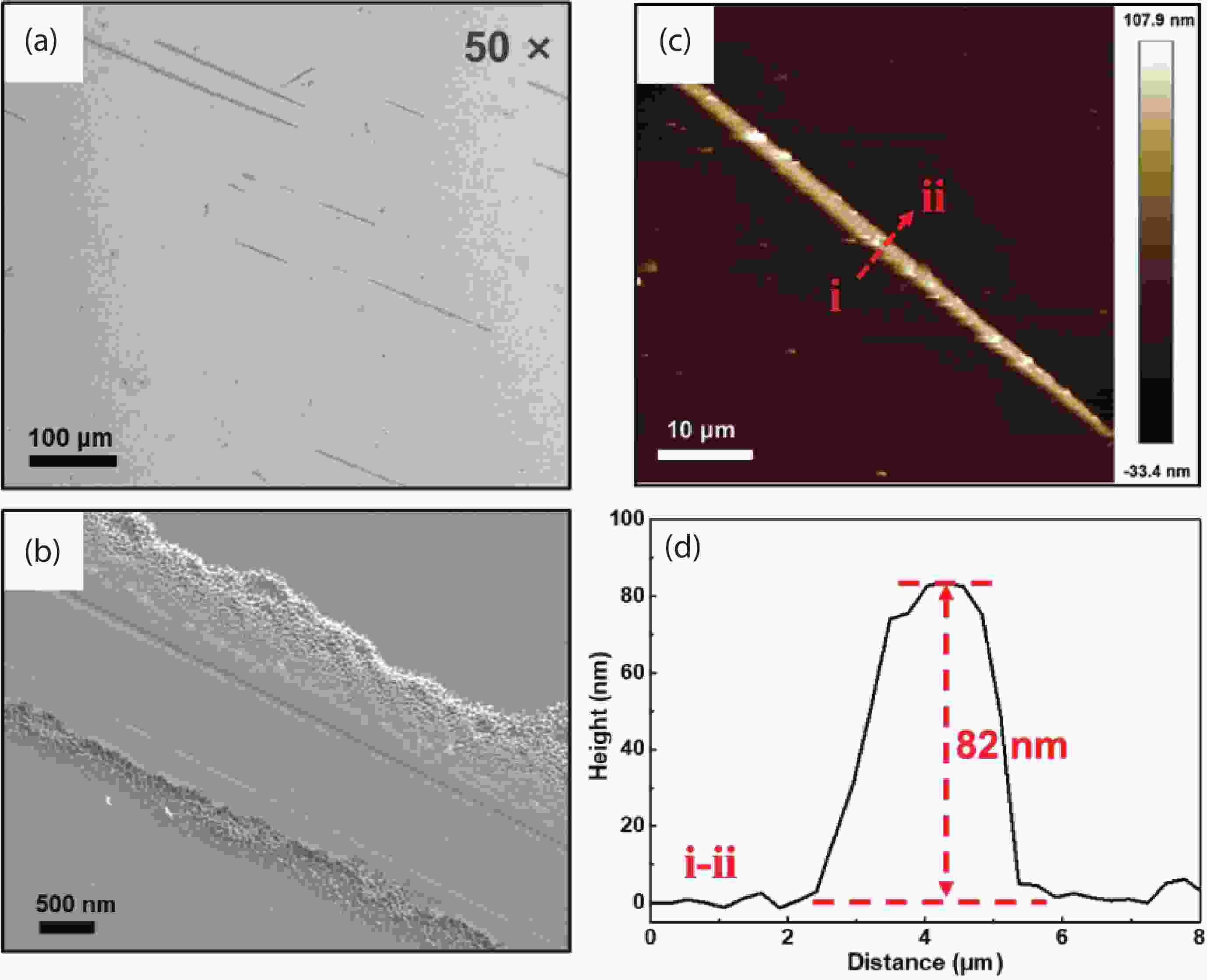

Identification Of Subsurface Damage Of 4h Sic Wafers By Combining Photo The calculations suggest that the p doping of cdte could be enhanced by forming the defect complexes of cl te −v cd. download : download full size image; fig. 3. calculated band structures and partial densities of states corresponding to (a) the ideal bulk of cdte and the defects of (b) v cd, (c) cl te and (d) cl te −v cd. the vertical. The parameters d 0, α and r 0 for cu c interaction are 0.1 ev, 1.7 Å −1 and 2.2 Å, respectively [34], it is also applied in the study of the mechanical behavior nanocrystalline cu sic composites [22]. for cu si, d 0, α and r 0 are 0.194 ev, 1.37 Å −1 and 2.5 Å, respectively [35].

Comments are closed.