Should I Replace Or Rebuild Damaged Hydraulic Cylinders

Should I Replace Or Rebuild Damaged Hydraulic Cylinders Prepare a clean and organized workspace. remove the cylinder from your machinery. disassemble your hydraulic cylinder and thoroughly inspect all seals, components, and fluids for wear, damage, or contamination. replace all worn or damaged components following instructions in the manufacturer’s manual. reassemble your hydraulic cylinder. It can also be difficult to find a replacement for a non standard cylinder. covid 19 has made it difficult to find certain products, including cylinders. if you can't easily find a replacement, hydraulic cylinder repairs may be the better choice. what to choose: repair. number of damaged parts of hydraulic cylinder.

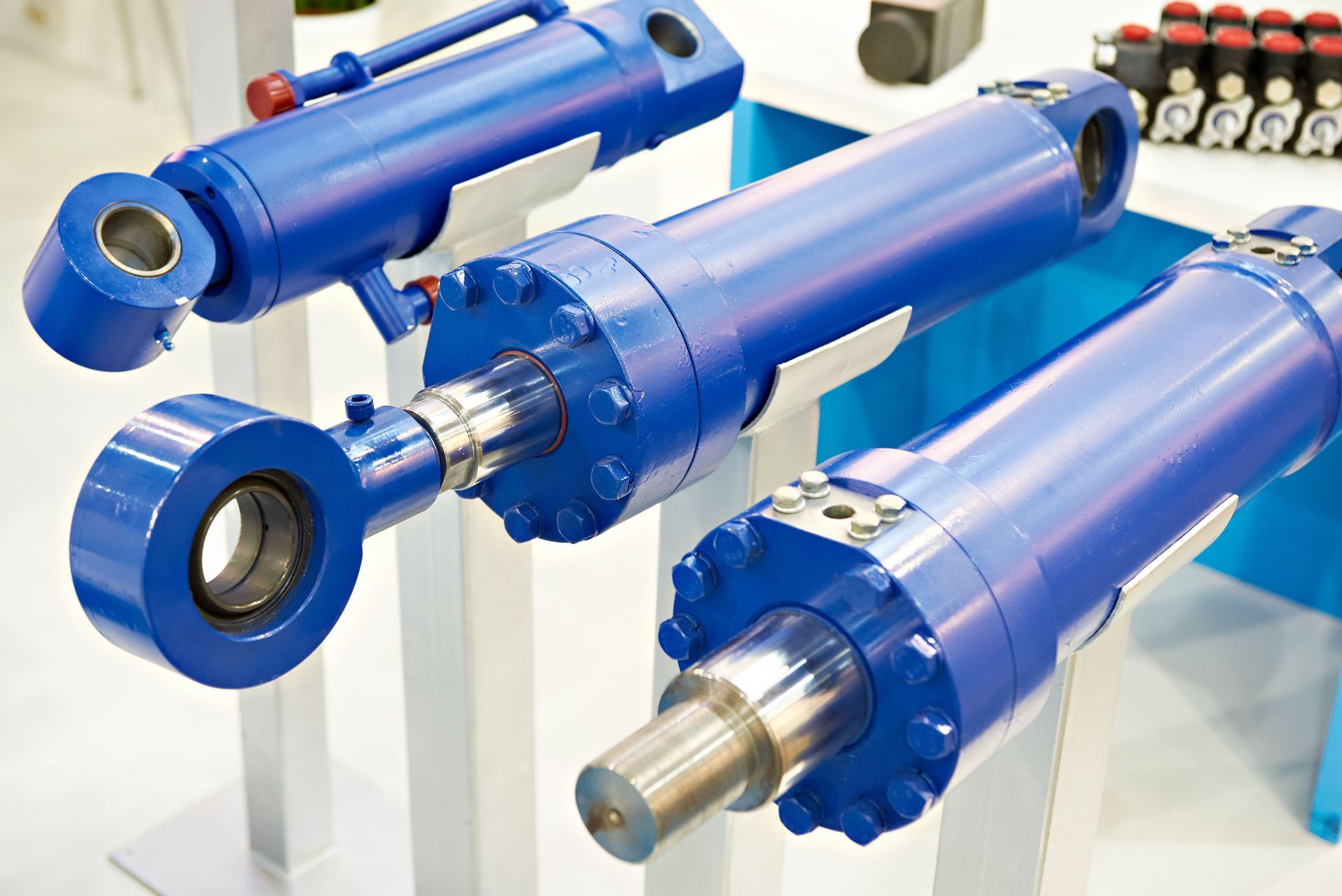

Should You Repair Or Replace A Damaged Hydraulic Cylinder Depending on the location and severity of the hydraulic cylinder damage, it may be more cost effective to replace the hydraulic cylinder assembly. most cylinders can be repaired economically if the damage is limited to the seals, head glands, pistons, bushings, or removable mounts. if rod assembly or barrel assembly replacement is required. By dan anderson june 7, 2022. a seal kit to rebuild a leaky hydraulic cylinder is always cheaper than the cost of a new cylinder. but there are times when it is more economical (not necessarily. There are many benefits to repairing a hydraulic cylinder. in most cases of failure, a specific component fails rather than the entire system, leaving other parts in excellent condition as long as the failure is caught relatively quickly. in such cases, only the damaged part needs to be replaced as is common with bearing and seal problems. Hydraulic cylinder failure primarily stems from contaminated fluid and damaged seals. failure can also be caused by excessive wear or sudden damage to hard parts. a bent piston rod will cause a cylinder to fail rapidly if not immediately. to repair or to replace. a hydraulic cylinder that is beyond repair is usually obvious.

When Is It Worth Repairing A Hydraulic Cylinder Cylinders Inc There are many benefits to repairing a hydraulic cylinder. in most cases of failure, a specific component fails rather than the entire system, leaving other parts in excellent condition as long as the failure is caught relatively quickly. in such cases, only the damaged part needs to be replaced as is common with bearing and seal problems. Hydraulic cylinder failure primarily stems from contaminated fluid and damaged seals. failure can also be caused by excessive wear or sudden damage to hard parts. a bent piston rod will cause a cylinder to fail rapidly if not immediately. to repair or to replace. a hydraulic cylinder that is beyond repair is usually obvious. Cost considerations in cylinder repair and rebuild. how much does it cost to rebuild a hydraulic cylinder? the cost can vary widely based on several factors including the size of the cylinder, the extent of damage, and the cost of replacement parts like seals and piston rods. prices can range from a few hundred to several thousand dollars. To remove a hydraulic cylinder piston nut, you’ll need: secure the rod: hold the piston rod securely, often in a vice with protective jaws to prevent damage. use the right tool: employ a wrench or socket that fits the piston nut. apply force carefully: gradually apply force to turn the nut.

Should I Replace Or Rebuild Damaged Hydraulic Cylinders Cost considerations in cylinder repair and rebuild. how much does it cost to rebuild a hydraulic cylinder? the cost can vary widely based on several factors including the size of the cylinder, the extent of damage, and the cost of replacement parts like seals and piston rods. prices can range from a few hundred to several thousand dollars. To remove a hydraulic cylinder piston nut, you’ll need: secure the rod: hold the piston rod securely, often in a vice with protective jaws to prevent damage. use the right tool: employ a wrench or socket that fits the piston nut. apply force carefully: gradually apply force to turn the nut.

When Is It Worth Repairing A Hydraulic Cylinder Rather Than Replacing

Comments are closed.