Should You Repair Or Replace A Damaged Hydraulic Cylinder

Should You Repair Or Replace A Damaged Hydraulic Cylinder Hydraulic cylinder starts “juddering”. a hydraulic cylinder lacking smooth and consistent movements is another sign of an underlying issue. “juddering” is when the cylinder becomes jerky or stilted as the cylinder extends. juddering is often caused by physical damage from increased friction, worn down seals, poor lubrication, or worse. Depending on the location and severity of the hydraulic cylinder damage, it may be more cost effective to replace the hydraulic cylinder assembly. most cylinders can be repaired economically if the damage is limited to the seals, head glands, pistons, bushings, or removable mounts. if rod assembly or barrel assembly replacement is required.

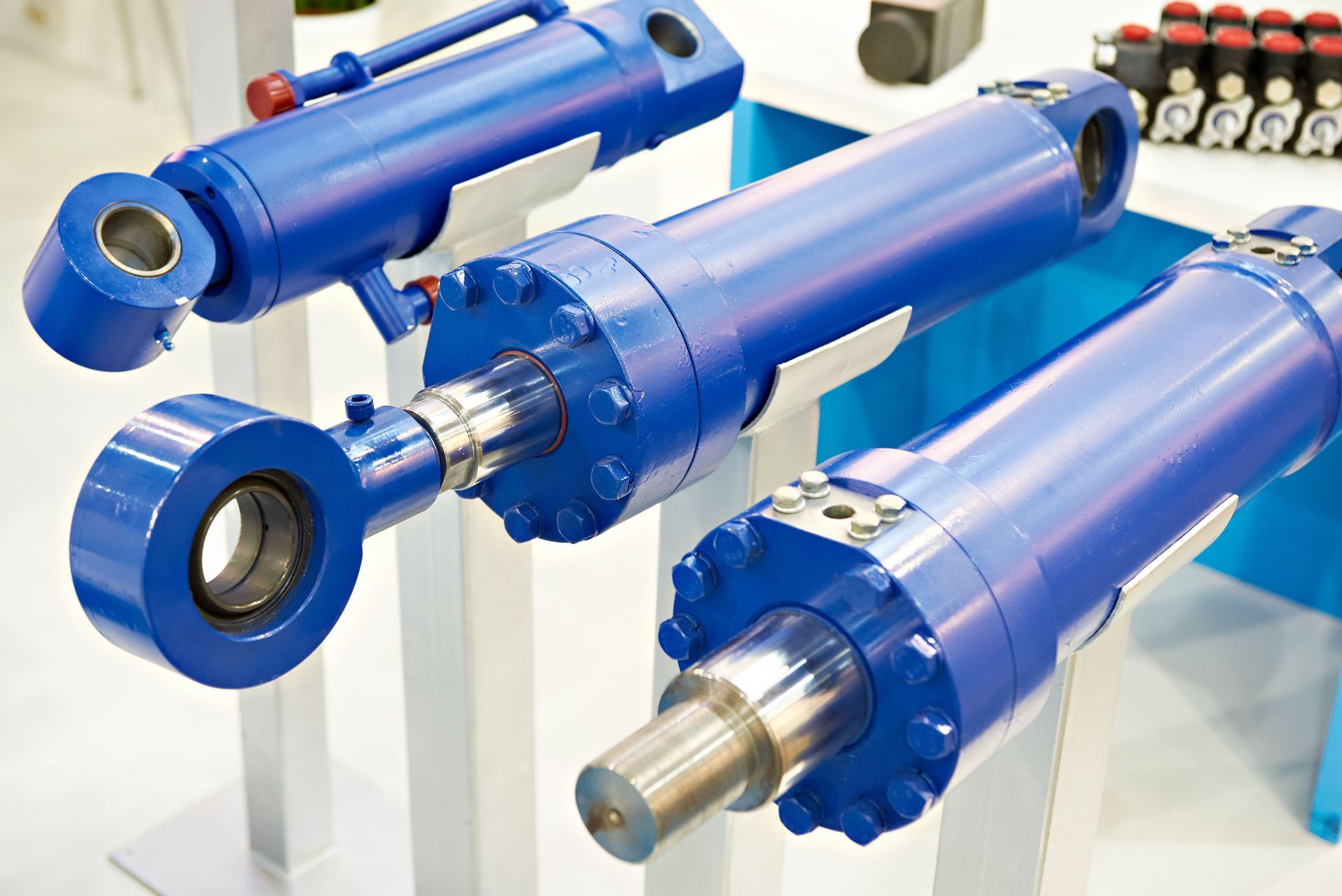

Should I Replace Or Rebuild Damaged Hydraulic Cylinders Prepare a clean and organized workspace. remove the cylinder from your machinery. disassemble your hydraulic cylinder and thoroughly inspect all seals, components, and fluids for wear, damage, or contamination. replace all worn or damaged components following instructions in the manufacturer’s manual. reassemble your hydraulic cylinder. These are just a few things you should think about when deciding to repair or replace your hydraulic cylinder. luckily, in most cases, a hydraulic cylinder repair professional can do repairs. if you are in need of hydraulic cylinder repairs or replacement, please contact kingdom builders machining and hydraulics today. There are many benefits to repairing a hydraulic cylinder. in most cases of failure, a specific component fails rather than the entire system, leaving other parts in excellent condition as long as the failure is caught relatively quickly. in such cases, only the damaged part needs to be replaced as is common with bearing and seal problems. To repair or to replace. a hydraulic cylinder that is beyond repair is usually obvious. the cylinder bore is cracked, the rod is severely bent or the entire cylinder is torched. however, most hydraulic cylinders can be repaired by an experienced hydraulic shop. often a cylinder can be repaired by simply repacking the cylinder with a seal kit.

When Is It Worth Repairing A Hydraulic Cylinder Cylinders Inc There are many benefits to repairing a hydraulic cylinder. in most cases of failure, a specific component fails rather than the entire system, leaving other parts in excellent condition as long as the failure is caught relatively quickly. in such cases, only the damaged part needs to be replaced as is common with bearing and seal problems. To repair or to replace. a hydraulic cylinder that is beyond repair is usually obvious. the cylinder bore is cracked, the rod is severely bent or the entire cylinder is torched. however, most hydraulic cylinders can be repaired by an experienced hydraulic shop. often a cylinder can be repaired by simply repacking the cylinder with a seal kit. To remove a hydraulic cylinder piston nut, you’ll need: secure the rod: hold the piston rod securely, often in a vice with protective jaws to prevent damage. use the right tool: employ a wrench or socket that fits the piston nut. apply force carefully: gradually apply force to turn the nut. Step 1: inspect the cylinder. start by inspecting the cylinder for any signs of damage or wear, such as dents, cracks, or corrosion. if any of these are present, it is best to replace the cylinder before attempting to repair it.

Comments are closed.